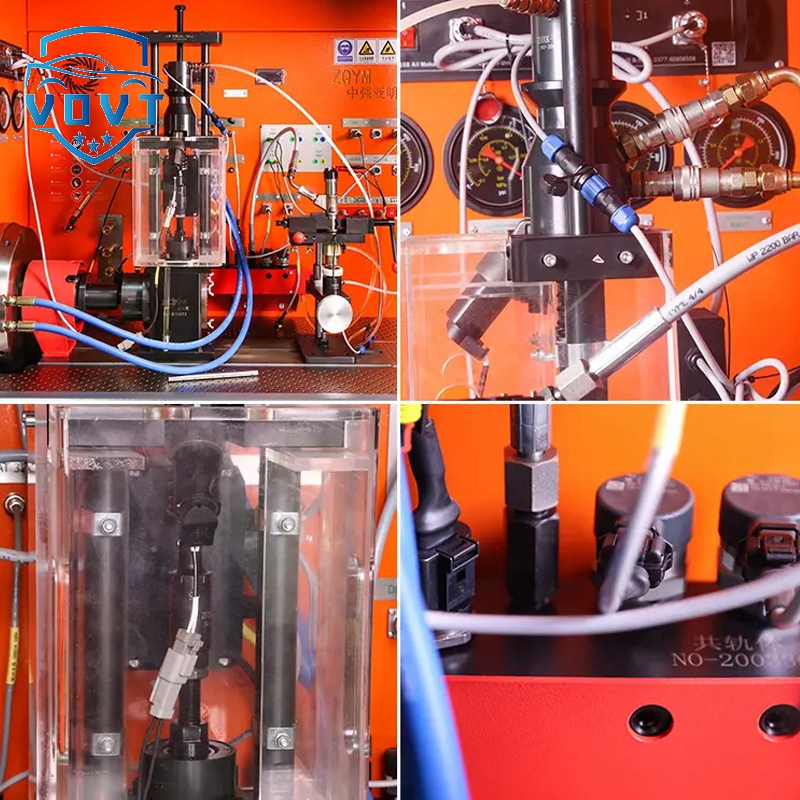

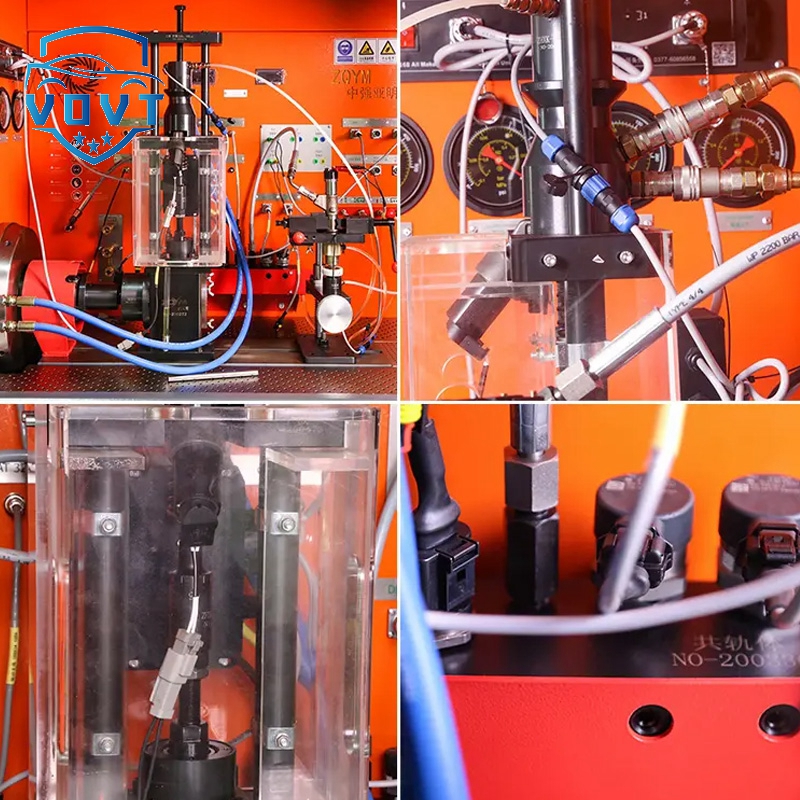

ZQYM-8320 Common Rail Diesel Fuel vp44 Injection Pump Test Bench HEUI injector Test Equipment pump tester simulator

| Supply voltage | 220VAC/380VAC |

| Voltage phase | two /three phase |

| frequency | 50HZ/60HZ |

| Current | 30A(Max) |

| Motor power | 22KW+5.5Kw |

| Application | DPF,SCR ,DOC regeneration |

| Operating temperature | heating/ forced air cooling |

| Max common rail pressure | 2700 Bar |

| ECU pressure-rise | 0-200V |

| Noise level | <70dB |

| Weight | 1450kg |

| size | 2130x1060x1840mm |

| Packing size | 2200x1200x2000mm |

ZQYM-8320 Common Rail Diesel Fuel vp44 Injection Pump Test Bench

Diesel engine performance depends largely on the precise adjustment of the fuel injection pump. Although the fuel injection pump test bench has strict technical requirements to ensure the accuracy of fuel injection pump parameter adjustment, if the use and maintenance are not done properly, the debugging quality of the fuel injection pump cannot be guaranteed.

1 Technical requirements of fuel injection pump test bench

(1) The scale error of the test bench should not exceed ±10' at any position, and the scale should be clear.

(2) The instantaneous speed fluctuation within each revolution of the output shaft of the test bench shall not exceed 1% of the test speed when the measured speed of the output shaft transmission disc is > 600 r/min; when the speed is ≤ 600 r/min, the instantaneous speed fluctuation shall be No more than 6 r/min.

(3) The counting mechanism of the test bench should be accurate and sensitive, and can count 100 to 1000 times in each gear, and the allowable counting error of the whole system is 1 time.

(4) The oil measuring cylinder of the test bench must have a clear and accurate scale, the minimum scale should not be greater than 1% of the full scale, and the scale error should be within 0.5% of the full scale.

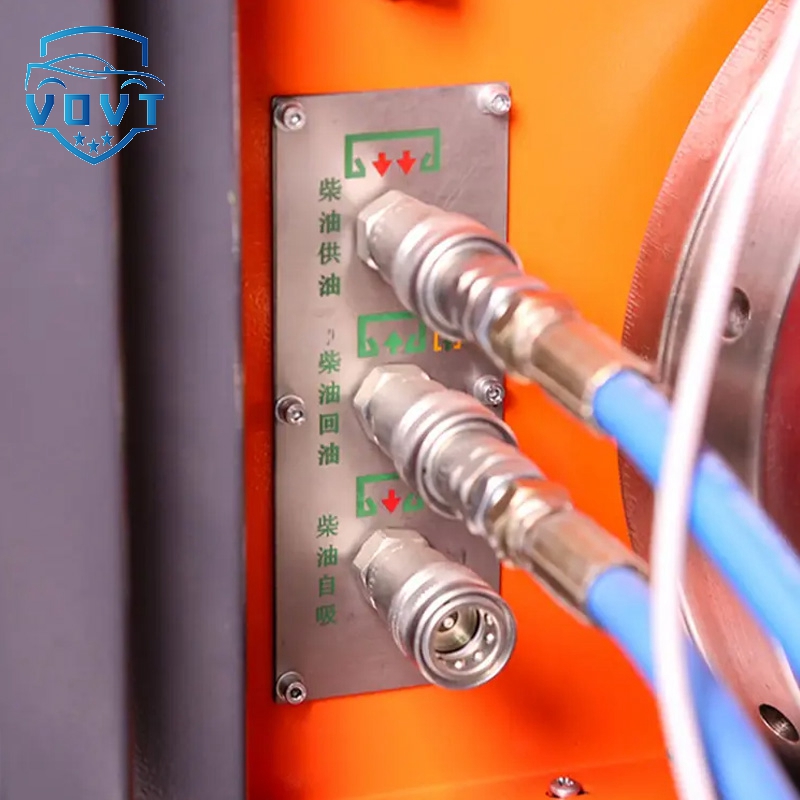

(5) The oil supply pressure of the test bench should be adjustable and kept stable. At the rated speed, when the outlets are all closed, the maximum pressure should reach: low-pressure oil circuit ≥ 0.4 MPa; high-pressure oil circuit ≥ 34 MPa.

(6) Parameters of the high-pressure fuel pipe for debugging the in-line fuel injection pump: length×outer diameter×inner diameter, of which 600 mm×6 mm×2 mm is used for debugging the fuel injection pump whose circulating fuel supply volume does not exceed 300 mm 3 ; 800 mm×8 mm×39 mm is used for commissioning of fuel injection pumps with circulating oil supply exceeding 300 mm; 800 mm×6 mm×2 mm is used for commissioning of distributed fuel injection pumps.

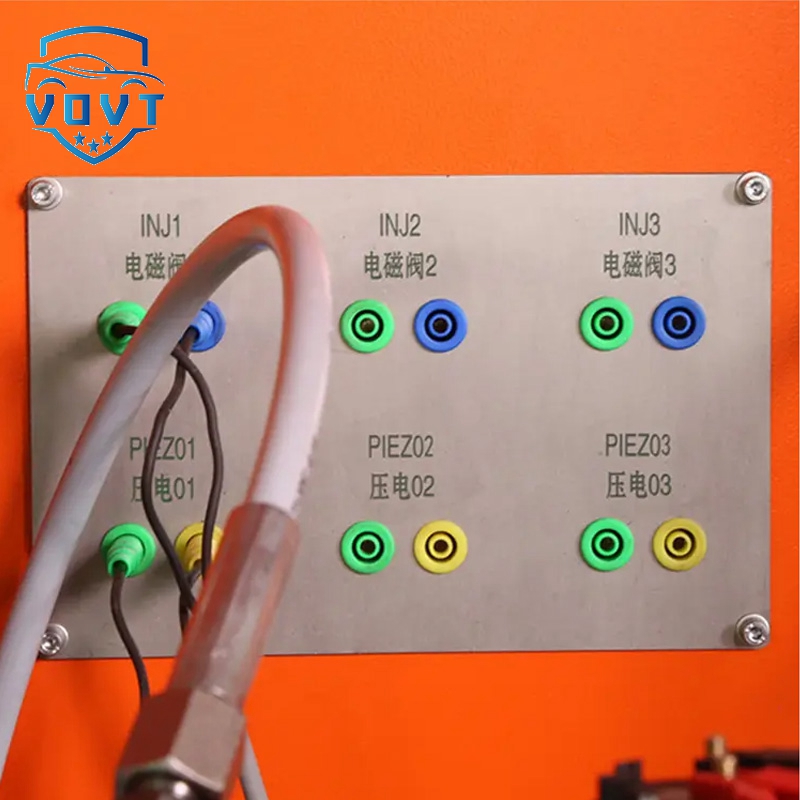

(7) The standard fuel injector selected by the test bench can be used to supply oil of no more than 300 mm3 per cycle. When the speed of the fuel injection pump is 1000 r/min, the oil supply gear rod is fixed at the position of 103 mm3 cycle. 1000 times the pump When the oil volume is in the range of 102-103 cm3, the opening pressure of the needle valve is 17.5 MPa.

(8) For the fuel injection pump in use, due to the limitation of the quality of use, the repaired fuel injector of the original vehicle should be used for the fuel injection pump test. In this way, the engine can be guaranteed to work under normal and uniform oil supply from the beginning until the fuel injector assembly is replaced. If a standard fuel injector is used for debugging, and the engine works with a non-standard fuel injector, it cannot work with the required uniformity of fuel supply, thus losing the significance of fuel injection pump debugging.

(9) The temperature of the test room has a great influence on the fuel supply of the fuel injection pump, because the degree of diesel oil changes with the temperature, and the standard fuel supply specified in the technical documents refers to the standard room temperature of 20 ℃. Fuel supply. A test has proved that when the temperature drops from 40°C to 6°C, the fuel supply can increase by 20% to 40%, and if the temperature is further lowered, the resistance of the high-pressure oil pipe and the injector will increase sharply due to the great increase in the degree of diesel oil , the fuel supply will decrease instead. In order to adjust the fuel supply accurately, the temperature of the test workshop should be kept in the normal temperature range of 15-20°C, especially the high-speed fuel injection pump is more sensitive to the change of fuel temperature.