ZQYM-6320S heui test bench equipment injector tester common rail diesel fuel injector test bench for bosch injector

| Supply voltage | 220VAC/380VAC |

| Voltage phase | two /three phase |

| Frequency | 50Hz/60Hz |

| Current | 30A(Max) |

| Motor power | 5.5KW |

| Oil Temperature Control | heating/ forced air cooling |

| Operating temperature | -10-35℃ |

| Max common rail pressure | 2700 Bar |

| ECU pressure-rise | 0-200V |

| Noise level | <85dB |

| Weight | 500kg |

| size | 1400x950x1670mm |

| Packing size | 1500x1100x1800mm |

common rail diesel injector test bench

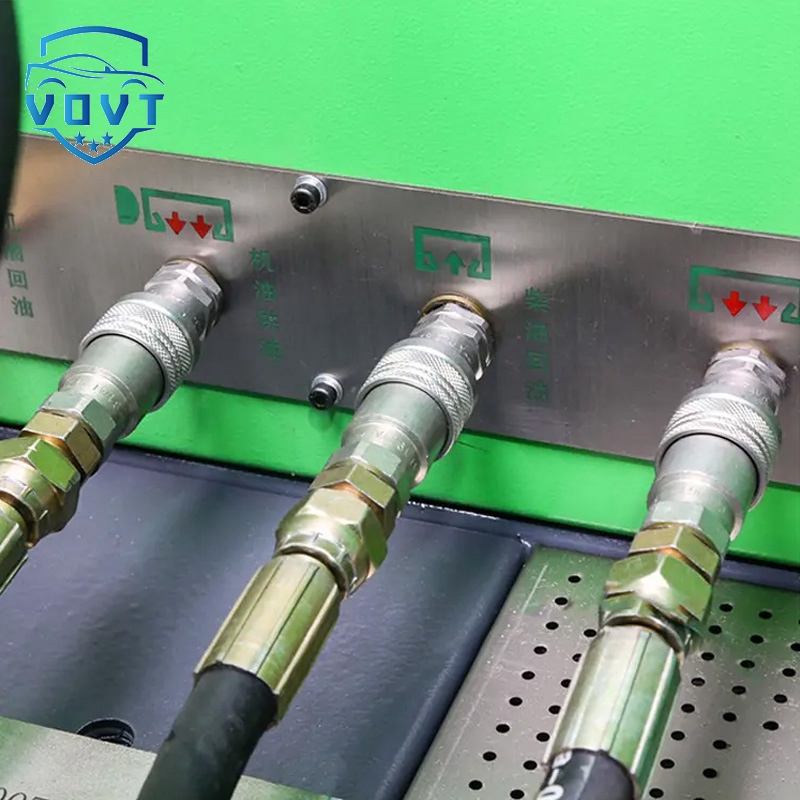

In the structural diagram of the embodiment of the electronically controlled common rail injector performance test bench, the fuel tank, the fuel filter, the high-pressure fuel supply pump and the electric motor are all installed under the working table of the test bench. The upper part of the test bench is equipped with a display that can display various parameters such as the single injection volume of the injector, the fuel return volume, the common rail pressure Pc, the speed of the fuel supply pump n, the fuel temperature tF, and the pulse width, and their changes. The test bench is also equipped with a keyboard for controlling the work of the test bench and inputting and adjusting parameters. On the working table of the test bench, there are single fuel injection gauges, fuel injector fixtures, electronically controlled fuel injectors under test, common rail and related pulse attenuators, high-pressure oil pipes and other components are arranged on the upper part of the test bench. Therefore, the design structure is reasonable, and the operation and use are convenient.

The schematic diagram of the electronically controlled common rail injector performance test bench shows the flow direction of the test oil and the connection of the oil return pipe in the test bench system. In order to control the fluctuation range of the common rail pressure on the test bench of the utility model, and ensure the accuracy and stability of the test results. In a typical embodiment, the pressure accumulation volume of the common rail is more than doubled than that of the common rail on the tested diesel engine, and the common rail is equipped with the same In addition to the common rail pressure sensor and pressure limiter, a pulsation attenuator is also installed. The design scheme of another embodiment is to make the pressure accumulation volume of the common rail on the test bench and the common rail on the diesel engine under test the same. In order to increase the pressure accumulation volume, two or more common rails can be connected in series or in parallel ; In order to further stabilize the common rail pressure, a pulsation attenuator can be added.