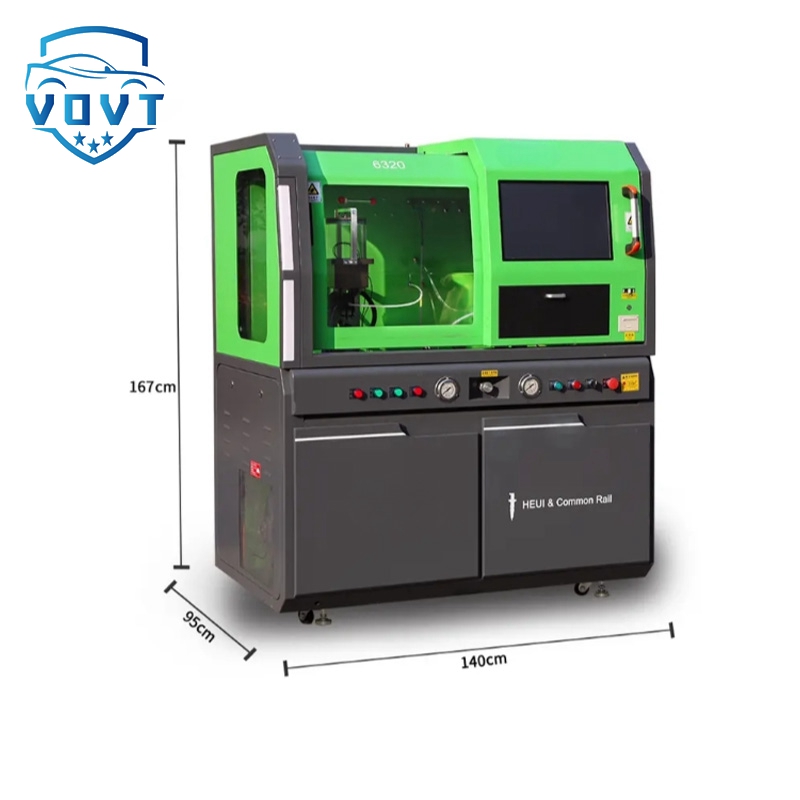

ZQYM-6320C High pressure test bench common rail diesel injector test bench machine for bosch /denso /delphi /siemens injector

| Supply voltage | 220VAC/380VAC |

| Voltage phase | two /three phase |

| Frequency | 50Hz/60Hz |

| Current | 30A(Max) |

| Motor power | 5.5KW |

| Oil Temperature Control | heating/ forced air cooling |

| Operating temperature | -10-35℃ |

| Max common rail pressure | 2700 Bar |

| ECU pressure-rise | 0-200V |

| Noise level | <85dB |

| Weight | 500kg |

| size | 1400x950x1670mm |

| Packing size | 1500x1100x1800mm |

common rail diesel injector test bench

Among the existing domestic and foreign publications and patent documents, Chinese patent 01126935.9 "Diesel Automobile Nozzle Detector" is a device for maintenance, which can modulate and display pulse width, but cannot measure fuel injection volume. European patent EP1343968 is applicable to ignition engine (gasoline engine), is not suitable for compression ignition engine (diesel engine). The patent FR2795139 of the French EFS company and the patent DE10061433 of the German R.Bosch company have proposed a method for measuring the transient fuel injection quantity (single injection quantity) of the internal combustion engine, but they are not an electronically controlled common rail fuel injection for practical use. Device performance test bench.

SUMMARY OF THE INVENTION The purpose of this utility model is to provide a performance test bench for electronically controlled common rail injectors that can test the single injection quantity of electronically controlled injectors for diesel engines.

The technical solution adopted by the utility model is to design a test bench for electric control common rail fuel injector integrated with electromechanical instrument. The test bench consists of bench (10), fuel filter (2), oil return valve (3) , high-pressure fuel supply pump (4), common rail (5), electronically controlled fuel injector (6), electronic controller (7), fuel injector fixture (8), electric motor (9), various sensors (11, 12 , 13...) and various oil pipes, instruments and other accessories; its characteristics are: (a) the fuel tank (1), fuel filter (2), high-pressure fuel supply pump (4) and electric motor (9) are placed in the test bench They are all installed under the workbench of the test bench (10); (b) the upper part of the test bench is equipped with a single injection quantity of the fuel injector, the oil return quantity and the common rail pressure Pc, the speed of the fuel supply pump n, and the fuel temperature Displays (20) of various parameters such as tF, pulse width and their changing conditions; (c) a keyboard (21) for controlling the work of the test bench and inputting and adjusting parameters is installed on the test bench; There is a single fuel injection meter (22), which is used to measure the fuel injection quantity per cycle of the electronically controlled fuel injector (6), or when multiple injections are used, to measure the fuel injection quantities of pre-injection, main injection and post-injection respectively , It can also measure the oil return volume of the injector. An oil temperature control system (30) for controlling the temperature of the fuel used for the test is also installed on the electric control common rail injector test bench, and the oil temperature control system is composed of parts such as a cooler and a temperature control switch. The cooler is a water-cooled oil-water heat exchanger or an air-cooled heat exchanger. The cooler can be installed in the fuel tank (1) or outside the fuel tank to form a separate component; when an air-cooled cooler is used, a cooling fan needs to be installed. The fuel injector fixture (8) in the above-mentioned test bench can be a pneumatic or hydraulic fixture that can be clamped quickly.