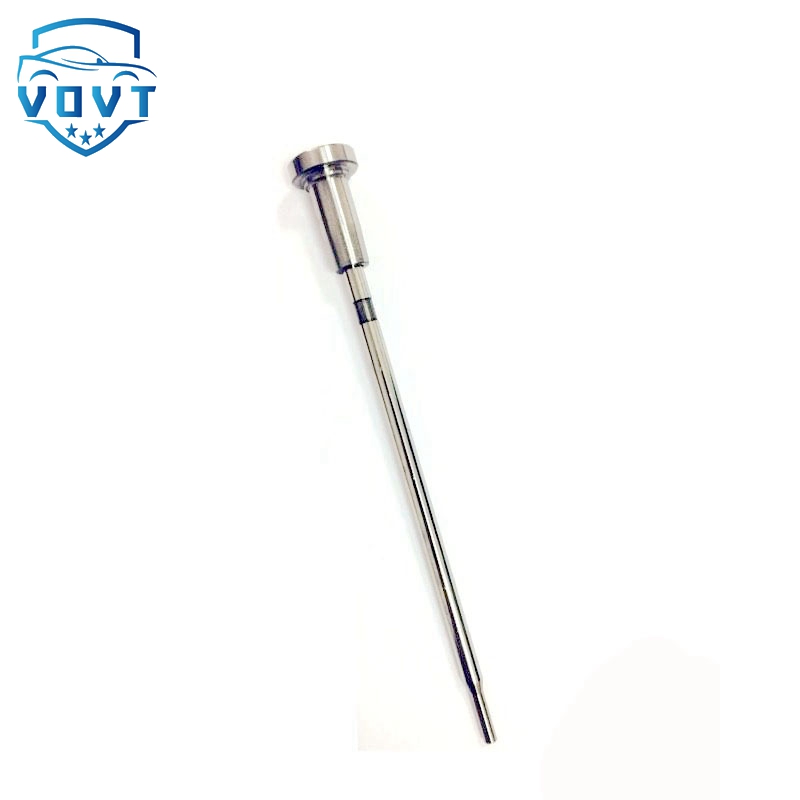

Common Rail Control Valve Set Assembly F00VC01037 & Injector Spare Part for Injector 0445110112 0445110187

| Produce Name | F00VC01037 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL,as your preference |

Inspection method of needle valve assembly of fuel injector

(1) Neck tightness test. Use mixed oil or 20# light diesel oil, and use the decompression method to carry out on a special test bench. During the test, use a hand pump to raise the pressure to 23-24 MPa, and measure the time for the pressure to drop from 20 MPa to 18 MPa. The test results are consistent with The standard product should be compared with the required range.

(2) Seat sealing test. Use 20# light diesel oil on a test bench with a pressure accumulator, first adjust the fuel injection pressure to the specified pressure of 12.5 MPa, and then increase the oil pressure by 0.1 MPa every 3 to 5 s evenly to the start of injection. Oil, observe the sealing quality, a small amount of oil leakage is allowed, and the diameter of the oil leakage is not more than 5 mm (the seat and the surface do not grind each other) or 3 mm in diameter (the seat and the surface grind each other). But not in a convex spherical shape.

(3) Spray test. Use 20# light diesel oil on the test bench, adjust the fuel injection pressure to 12.5 MPa, and carry out the spray test with the number of injections of 40-80 times/min.

The spray quality should meet the following requirements:

① The injected fuel should be atomized, and there should be no splashing oil particles and local uneven concentration that can be seen by the naked eye.

②The start and end of spraying should be obvious, and the sound should be crisp.

③Before the start of spraying and after the end of spraying, oil leakage is not allowed at the spray hole, but moisture is allowed.

(4) Check the spray angle. Check with the naked eye, compare the spray angle under the fuel injection pressure used on the diesel engine with the sample, and the deviation between the center line of the spray angle of the fuel injector and the center line of the fuel injector is not greater than 4°30'. The spray cone angle is observed within 100 mm.

(5) Sliding test. Carefully clean and lubricate the parts with well-filtered light diesel oil. When the needle valve is at 45° to the horizontal position, pull the needle valve out of the needle valve body by 1/3 of its own length. Turn it to any position and let it go. The weight itself slides freely without hindrance.