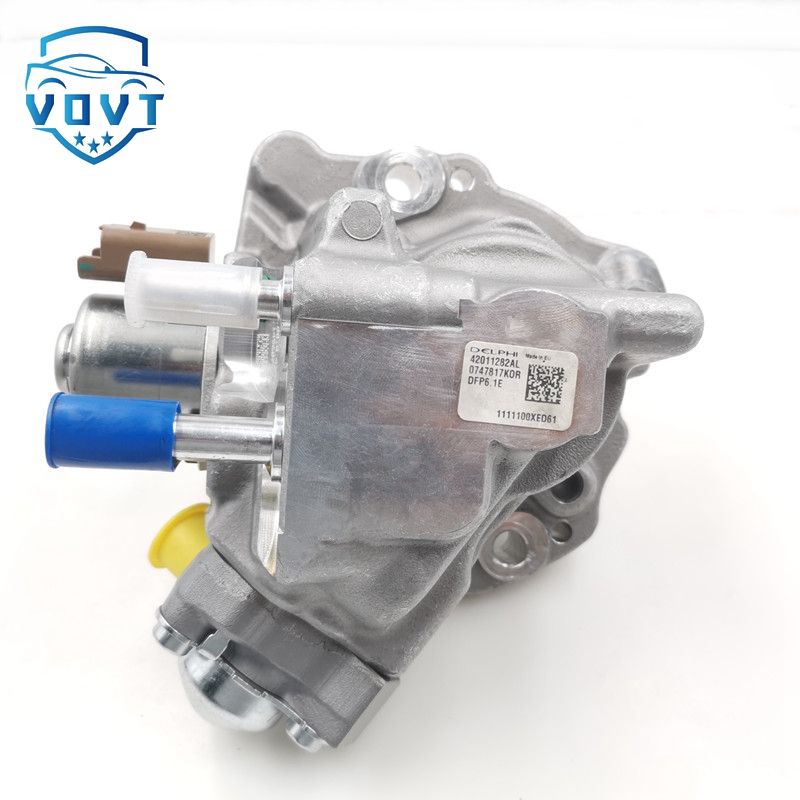

Fuel Injection Pump assembly 42011282AL Carter 320D common rail injector 32F61-00062 assembly 32F61-00062

| Produce Name | 42011282AL |

| Engine Model | / |

| Application | / |

| MOQ | 1 pcs / Negotiated |

| Packaging | plywood case Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Installation inspection and adjustment of fuel injection pump for diesel engine

The fuel injection pump is an important part of the fuel system of a diesel engine. Its working condition directly affects the power, economy and reliability of the diesel engine. Its function is to increase the oil pressure, control the injection time, and the injection volume to adjust the speed of the diesel engine. and power etc.

The oil outlet valve and plunger of the fuel injection pump are all precision coupling parts, which must be used as a set and are not allowed to be exchanged.

When installing the fuel injection pump, the starter handle should be pulled first so that the roller is at the lowest position. Fix the pointers on the shift fork and the fuel injection pump at the center of the sight hole, then press the fuel injection pump in place, turn the shift fork to see if the pointer moves with the shift fork, if so, tighten the upper two nuts first , and then install and tighten the gasket, cover plate and nut in sequence. Otherwise, take out the fuel injection pump, and readjust the position of the shift fork and pointer to assemble.

Remove the high-pressure oil pipe of the fuel injection pump, block the fuel outlet of the fuel injection pump with your fingers, and pull the start handle. If you feel that the fuel injection pressure is high, you can preliminarily think that the fuel injection pump is good. If you feel that the fuel injection pressure is low, it means that the fuel injection pump failure. Remove the tight seat of the oil outlet valve and turn the flywheel to see if the plunger moves up and down. If it does not move down, it means that the plunger spring is broken or the plunger is stuck near the top dead center. Otherwise, see if there is diesel oil flowing out of the oil outlet valve hole when the plunger goes down. If not, it means that the oil inlet hole of the oil pump is blocked and should be cleaned. If the oil supply pressure of the fuel injection pump is too low and the fuel supply volume is small, it is necessary to focus on checking whether the oil inlet hole of the fuel injection pump is blocked, whether the plunger couple is seriously worn, whether the fuel outlet valve couple and the camshaft are seriously worn.

Adjust the throttle handle to the starting position, first turn the flywheel clockwise quickly until the fuel injection pipe comes out. Then slowly turn the flywheel clockwise, and stop turning after the fuel injection pipe comes out. Rotate the flywheel counterclockwise to about 90 degrees after top dead center, and wipe off the residual fuel at the outlet of the fuel injection pipe with a rag. Then slowly turn the flywheel clockwise, and observe the outlet of the fuel injection pipe at this time. When there is a sign of oil coming out of the outlet, stop rotating the flywheel. Read the value of the engraved line on the flywheel that is aligned with the top dead center mark of the box body, which is the fuel supply advance angle at this time.

The standard fuel injection advance angle is 17-19 degrees. If the reading is greater than 19 degrees, the thickness of the adjusting gasket under the fuel injection pump should be increased; if it is less than 17 degrees, the thickness of the adjusting gasket under the fuel injection pump should be reduced. Generally, the gasket thickness is increased/decreased by 0.1mm, and the fuel injection advance angle is delayed/advanced by 1 degree.