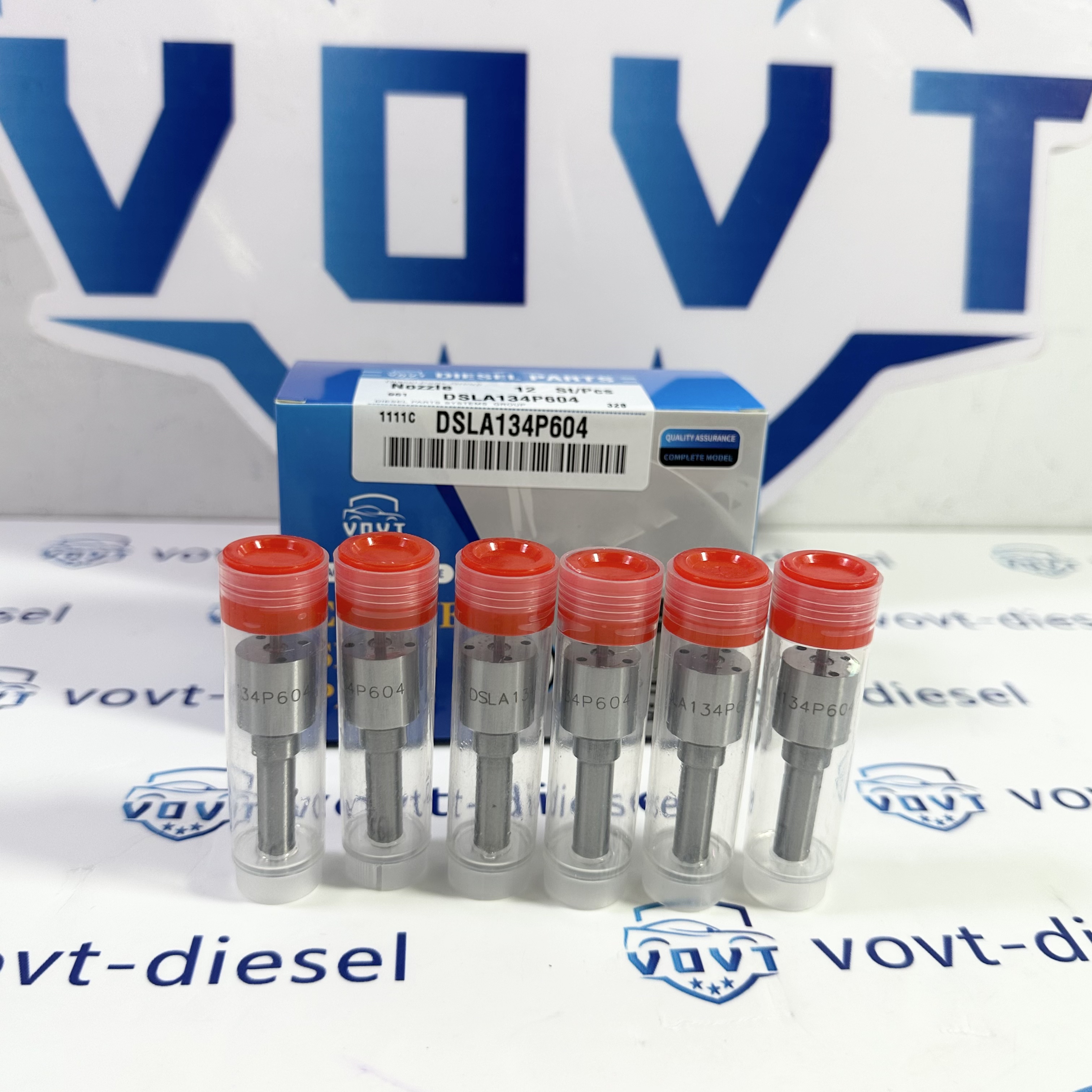

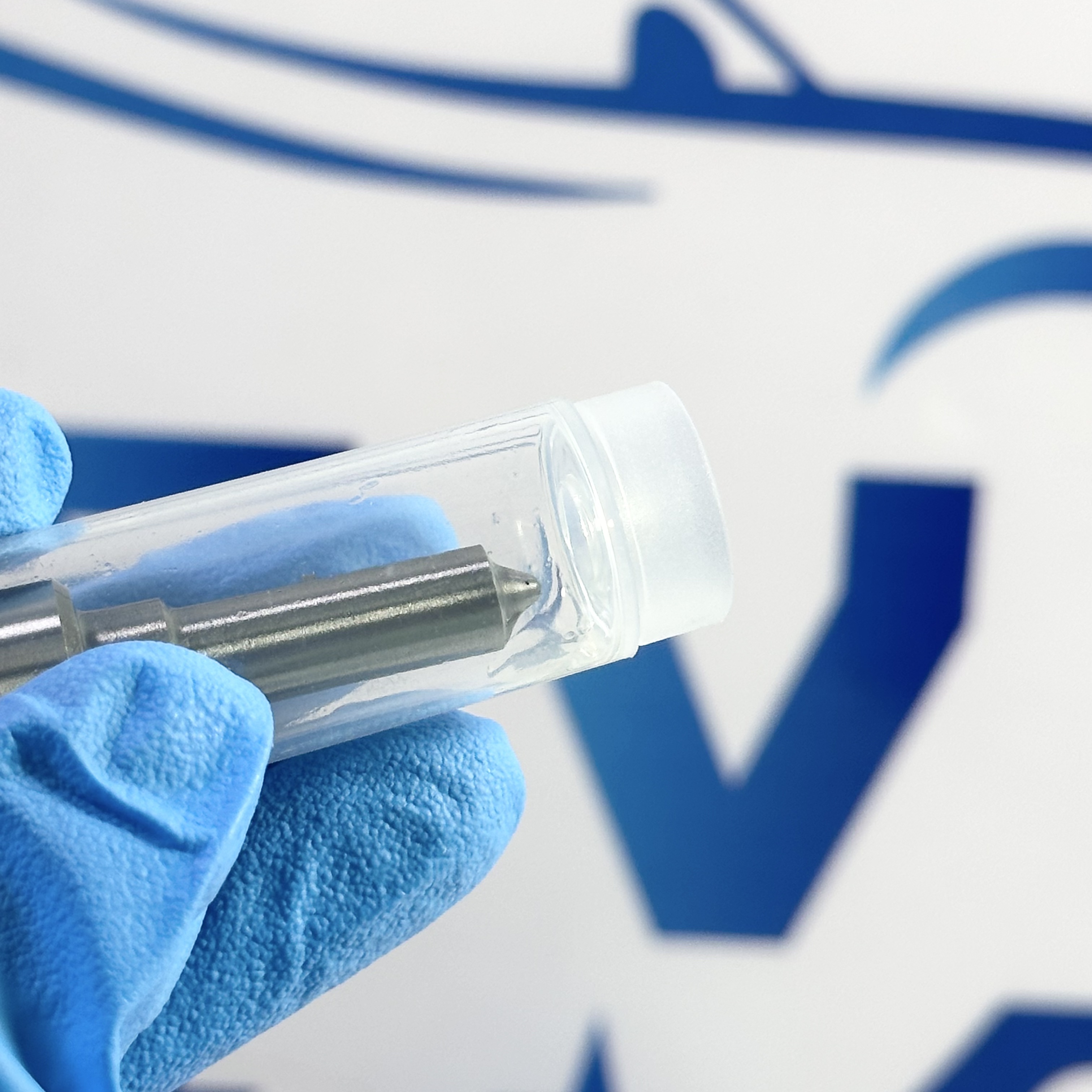

New High Quality Diesel Nozzle DSLA134P604 for Injection Nozzle Diesel Engine Parts

Products Description

| Reference. Codes | DSLA134P604 |

| Application | / |

| MOQ | 4PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Laser Cladding Strengthening Process and Wear Resistance Mechanism of High-Temperature Alloy Injector Nozzles

Abstract

Injector nozzles in modern diesel and gasoline direct injection systems operate under severe conditions of high temperature, high pressure, and corrosive fuel environments. Conventional nozzle materials often suffer from wear, erosion, and fatigue damage, which compromise fuel atomization and engine performance. Laser cladding has emerged as an advanced surface engineering technique for reinforcing high-temperature alloy nozzles. This paper investigates the strengthening process of laser cladding applied to injector nozzles and analyzes the underlying wear resistance mechanisms.

1. Introduction

High-pressure fuel injection systems demand nozzles with excellent strength, hardness, and wear resistance to maintain long-term stability of spray characteristics. High-temperature alloys, such as nickel-based and cobalt-based materials, are widely used due to their thermal stability. However, their intrinsic wear resistance under high-pressure cyclic loading remains insufficient. Laser cladding offers a promising solution by depositing wear-resistant coatings with metallurgical bonding and controllable microstructure.

2. Laser Cladding Strengthening Process

Laser cladding involves using a high-energy laser beam to melt alloy powders onto the nozzle surface, forming a dense, metallurgically bonded coating. The process offers:

-

Precise control of cladding thickness and geometry, suitable for micro-scale injector components.

-

Rapid solidification, leading to fine-grained microstructures with high hardness.

-

Flexibility in material selection, enabling the incorporation of carbides, ceramics, or composite phases for enhanced wear resistance.

Key parameters such as laser power, scanning speed, and powder feed rate determine coating quality, residual stress distribution, and bonding strength.

3. Wear Resistance Mechanisms

The improved wear resistance of laser-cladded injector nozzles can be attributed to several mechanisms:

-

Microstructural refinement: Fine-grained martensite or dendritic structures increase hardness and reduce abrasive wear.

-

Dispersion strengthening: Hard phases such as WC, TiC, or ceramic reinforcements act as load-bearing particles, reducing material removal.

-

Metallurgical bonding: Strong interface bonding prevents delamination during cyclic loading.

-

Oxidation and corrosion resistance: Alloying elements in the cladded layer form stable oxide films, reducing chemical attack in aggressive fuel environments.

4. Experimental Verification and Performance Improvement

Experimental studies show that laser-cladded high-temperature alloy nozzles exhibit:

-

Increased microhardness (up to 2–3 times higher than the substrate).

-

Significant reduction in wear volume and erosion rate under high-pressure fuel flow.

-

Stable spray cone angle and droplet size distribution over extended operation, indicating improved durability of atomization performance.

5. Conclusion

Laser cladding is an effective technique for enhancing the wear resistance of high-temperature alloy injector nozzles. The strengthening mechanisms involve microstructural refinement, hard-phase reinforcement, and improved surface stability under high-pressure and high-temperature conditions. By tailoring process parameters and coating composition, laser cladding offers a practical pathway to extend nozzle service life and ensure reliable fuel atomization in next-generation high-efficiency engines.

Related products

| NO. | STAMPING NO. | ORIGINAL NO. |

| 1 | DLLA140PN003 | 105017-0030 |

| 2 | DLLA140PN013 | 105017-0130 |

| 3 | DLLA140PN291 | 105017-2910 |

| 4 | DLLA143PN265 | 105017-2650 |

| 5 | DLLA143PN325 | 105017-3250 |

| 6 | DLLA145PN238 | 105017-2380 |

| 7 | DLLA146PN028 | 105017-0280 |

| 8 | DLLA146PN055 | 105017-0550 |

| 9 | DLLA146PN218 | 105017-2180 |

| 10 | DLLA146PN220 | 105017-2200 |

| 11 | DSLA149PN903 | 105017-9030 |

| 12 | DLLA150PN021 | 105017-0211 |

| 13 | DLLA150PN056 | 105017-0560 |

| 14 | DLLA150PN088 | 105017-0880 |

| 15 | DLLA150PN315 | 105017-3150 |

| 16 | DLLA151PN086 | 105017-0860 |

| 17 | DLLA152PN009 | 105017-0090 |

| 18 | DLLA152PN014 | 105017-0140 |

| 19 | DLLA152PN184 | 105017-1840 |

| 20 | DLLA152PN063 | 105017-0630 |

| 21 | DLLA152PN077 | 105017-0770 |

| 22 | DLLA153PN152 | 105017-1520 |

| 23 | DLLA153PN177 | 105017-1770 |

| 24 | DLLA153PN178 | 105017-1780 |

| 25 | DLLA153PN203 | 105017-2030 |

| 26 | DLLA154PN005 | 105017-0051 |

| 27 | DLLA154PN006 | 105017-0061 |

| 28 | DLLA154PN007 | 105017-0700 |

| 29 | DLLA154PN0171 | 105017-0171 |

| 30 | DLLA154PN040 | 105017-0400 |

| 31 | DLLA154PN049 | 105017-0490 |

| 32 | DLLA154PN061 | 105017-0610 |

| 33 | DLLA154PN062 | 105017-0620 |

| 34 | DLLA154PN064 | 105017-0640 |

| 35 | DLLA154PN067 | 105017-0670 |

| 36 | DLLA154PN068 | 105017-0680 |

| 37 | DLLA154PN087 | 105017-0870 |

| 38 | DLLA154PN089 | 105017 -0890 |

| 39 | DLLA154PN101 | 105017-1010 |

| 40 | DLLA154PN116 | 105017-1160 |

| 41 | DLLA154PN155 | 105017-1550 |

| 42 | DLLA154PN0171 | 105017-0171 |

| 43 | DLLA154PN185 | 105017-1850 |

| 44 | DLLA154PN186 | 105017-1860 |

| 45 | DLLA154PN208 | 105017-2080 |

| 46 | DLLA154PN270 | 105017-2700 |

| 47 | DLLA154PN940 | 105017-9400 |

| 48 | DLLA155PN046 | 105017-0460 |

| 49 | DLLA155PN053 | 105017-0530 |

| 50 | DLLA155PK107 | 105017-1070 |