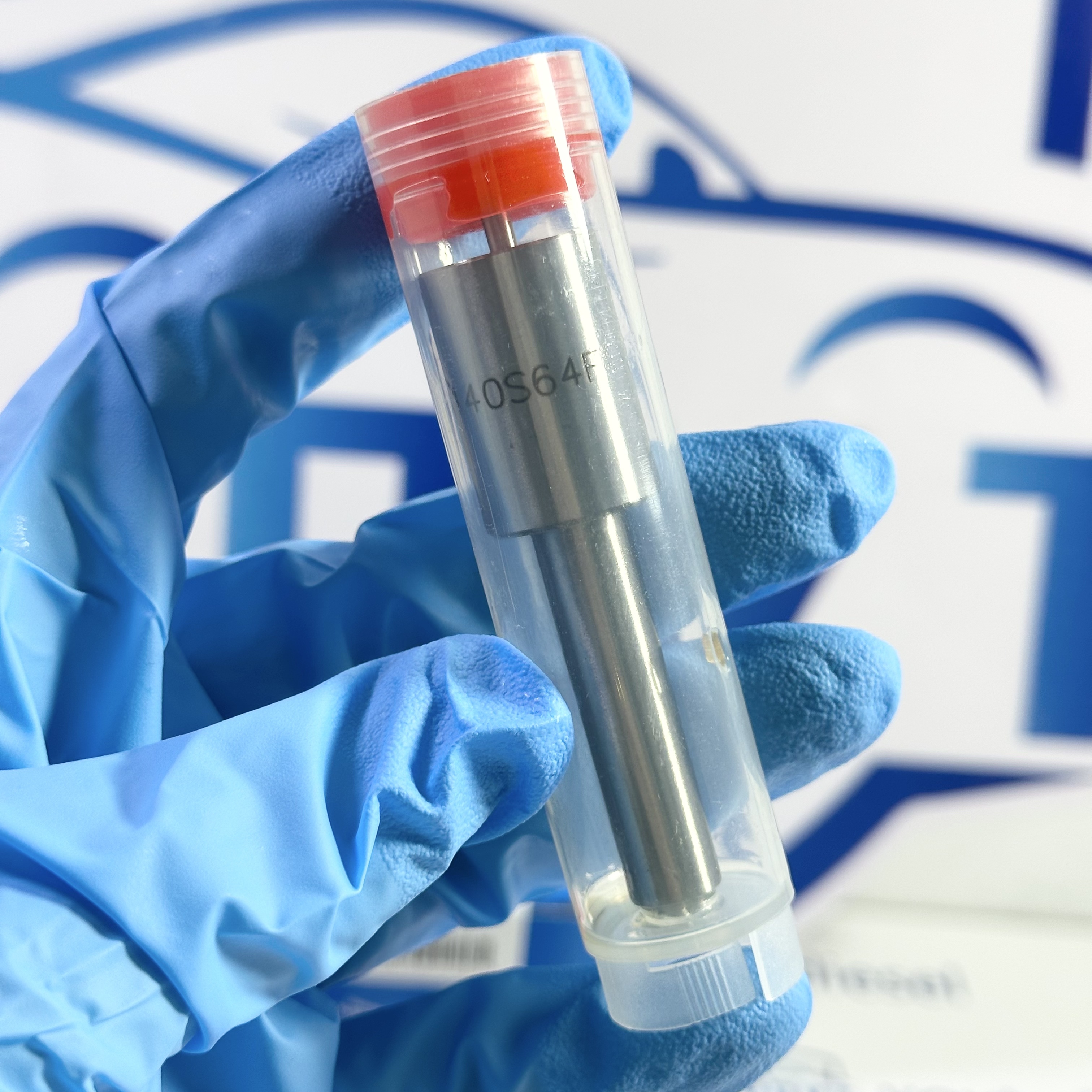

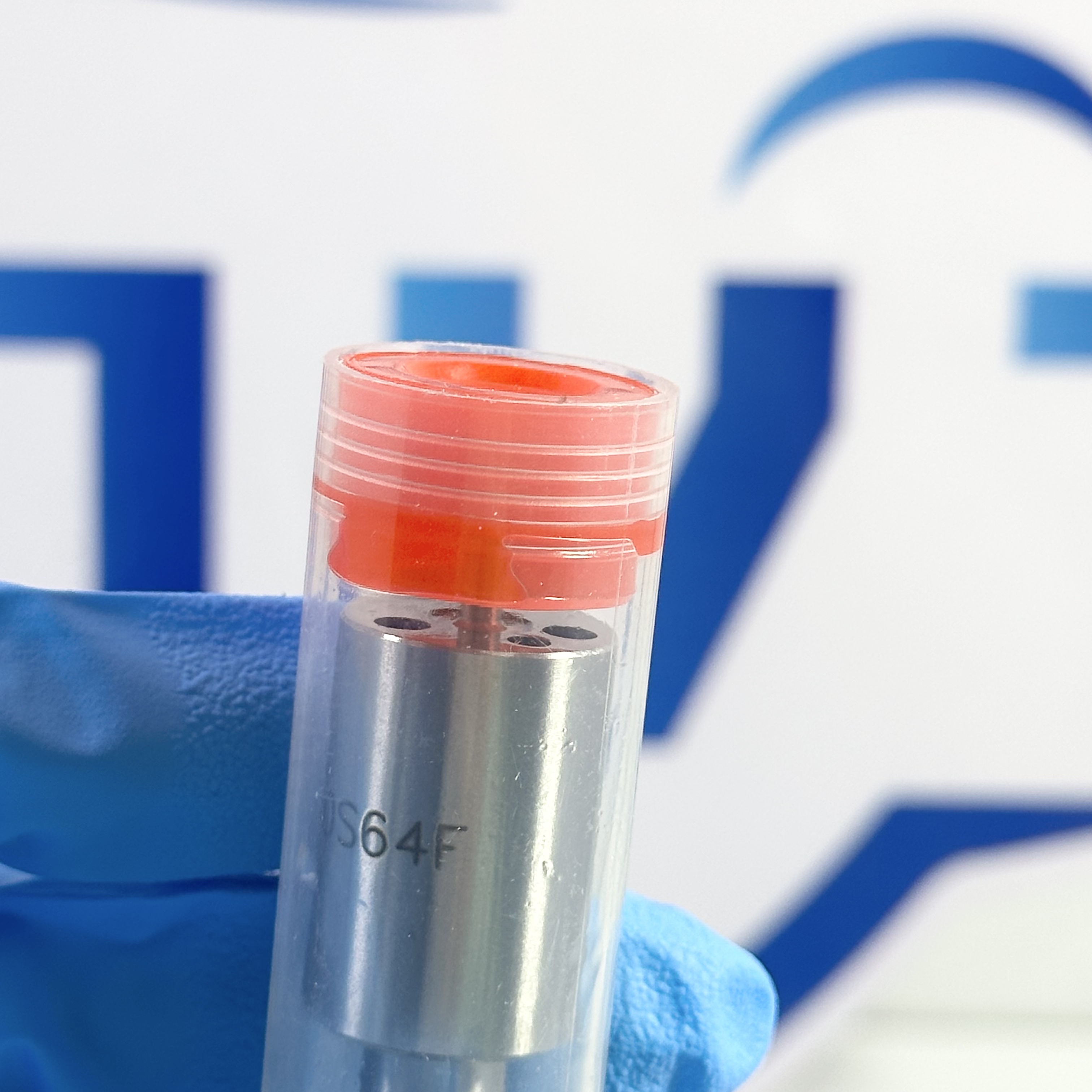

New High Quality Diesel Nozzle DLLA140S64F for Injection Nozzle Diesel Engine Parts

Products Description

| Reference. Codes | DLLA140S64F |

| Application | / |

| MOQ | 4PCS |

| Certification | ISO9001 |

| Place of Origin | China |

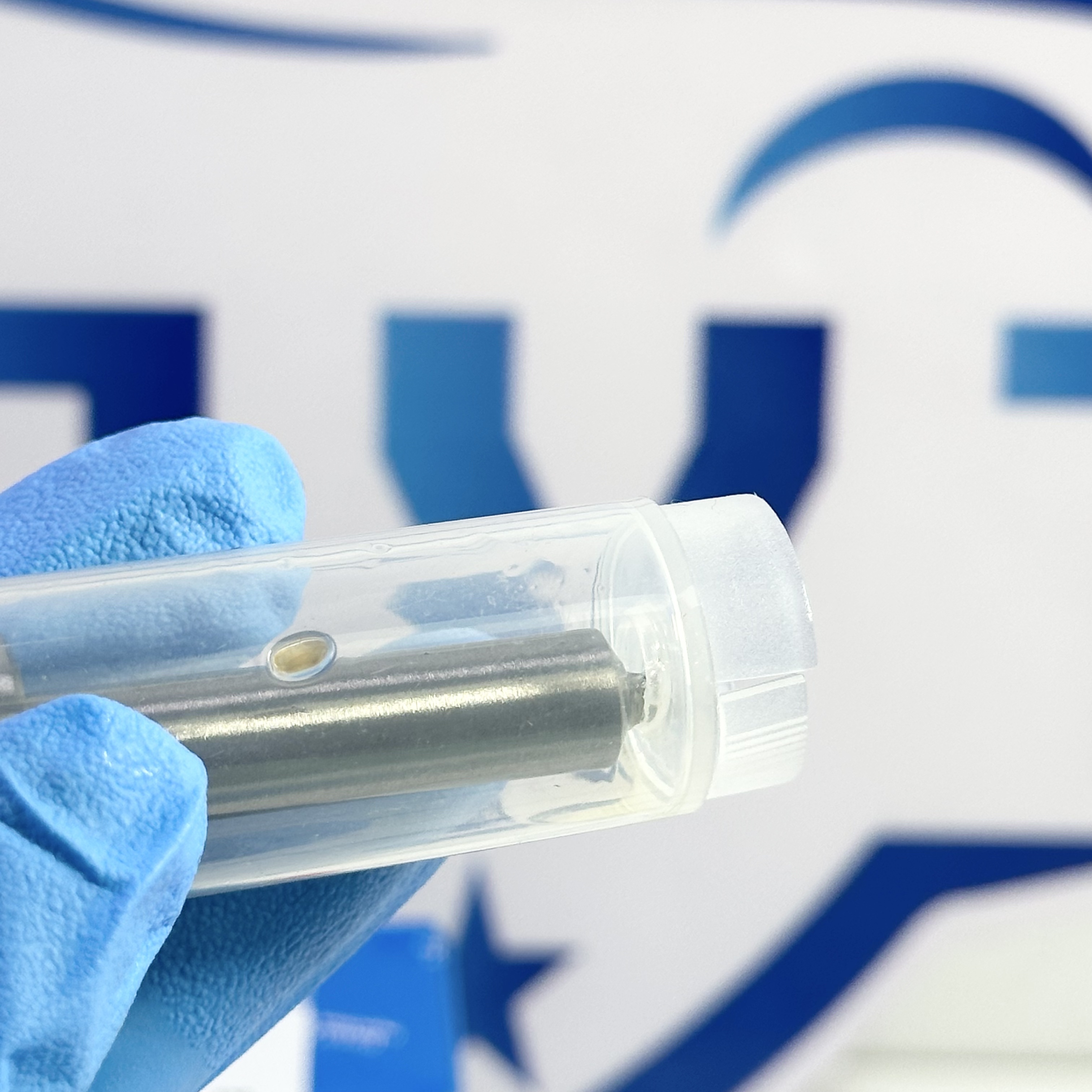

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Tribological Characteristics and Failure Modes of Diamond-Like Carbon (DLC) Coated Injector Nozzles

Abstract

Diamond-Like Carbon (DLC) coatings are widely applied to injector nozzles to improve wear resistance, reduce friction, and extend service life under harsh fuel injection environments. However, despite their superior tribological properties, DLC coatings are susceptible to specific failure modes when subjected to extreme pressure, high temperature, and cyclic loading. This paper examines the tribological behavior of DLC-coated injector nozzles and analyzes the mechanisms behind their failure modes.

1. Introduction

Modern fuel injection systems operate under ultra-high pressures exceeding 200 MPa, where injector nozzles are exposed to severe mechanical and chemical stresses. Conventional metallic surfaces often suffer from abrasive wear, adhesion, and erosion, leading to deteriorated spray performance. DLC coatings, with their high hardness, low friction coefficient, and chemical inertness, have emerged as effective protective layers. Investigating their tribological performance and failure mechanisms is essential for optimizing nozzle design and ensuring long-term durability.

2. Tribological Characteristics of DLC Coatings

The excellent tribological performance of DLC coatings can be attributed to the following properties:

-

Low friction coefficient (0.05–0.2): Reduces sliding resistance between the nozzle and fuel flow or moving parts.

-

High hardness (15–30 GPa): Provides resistance to abrasive wear under high-pressure injection.

-

Chemical inertness: Protects against corrosion from biodiesel, ethanol blends, and other aggressive fuels.

-

Solid lubrication effect: Graphitic phases within DLC coatings form transfer films that further reduce wear.

These properties contribute to improved fuel spray stability, reduced leakage, and longer service intervals for injector nozzles.

3. Failure Modes of DLC-Coated Injector Nozzles

Despite their advantages, DLC coatings may fail under prolonged service in high-pressure environments through several mechanisms:

-

Delamination and spallation: Poor adhesion or high residual stresses at the coating–substrate interface can lead to peeling under cyclic loading.

-

Micro-cracking: High contact stresses cause crack initiation within the coating, eventually propagating and exposing the substrate.

-

Thermal degradation: Elevated temperatures may induce graphitization, reducing hardness and increasing friction.

-

Erosion wear: Continuous impingement of high-velocity fuel droplets or particulates may thin and erode the coating.

-

Chemical attack: Certain fuel additives may weaken interfacial bonding, accelerating coating failure.

4. Strategies for Enhancing Durability

To mitigate failure modes and extend the lifespan of DLC coatings, several strategies can be adopted:

-

Optimizing deposition techniques (e.g., PECVD, magnetron sputtering) to improve coating density and adhesion.

-

Introducing interlayers (e.g., Cr, Ti) to reduce residual stress and enhance bonding strength.

-

Tailoring hydrogen content and sp²/sp³ ratios to balance hardness and toughness.

-

Applying multi-layer or nanocomposite DLC coatings for improved resistance to cracking and erosion.

5. Conclusion

DLC coatings significantly enhance the tribological performance of injector nozzles, offering low friction, high hardness, and excellent chemical stability. However, their failure modes—such as delamination, cracking, and thermal degradation—pose challenges under extreme service conditions. By optimizing coating design, deposition processes, and interfacial engineering, the durability and reliability of DLC-coated injector nozzles can be further improved, supporting the development of next-generation high-efficiency, low-emission engines.

Related products

| NO. | STAMPING NO. | ORIGINAL NO. |

| 1 | DLLA140PN003 | 105017-0030 |

| 2 | DLLA140PN013 | 105017-0130 |

| 3 | DLLA140PN291 | 105017-2910 |

| 4 | DLLA143PN265 | 105017-2650 |

| 5 | DLLA143PN325 | 105017-3250 |

| 6 | DLLA145PN238 | 105017-2380 |

| 7 | DLLA146PN028 | 105017-0280 |

| 8 | DLLA146PN055 | 105017-0550 |

| 9 | DLLA146PN218 | 105017-2180 |

| 10 | DLLA146PN220 | 105017-2200 |

| 11 | DSLA149PN903 | 105017-9030 |

| 12 | DLLA150PN021 | 105017-0211 |

| 13 | DLLA150PN056 | 105017-0560 |

| 14 | DLLA150PN088 | 105017-0880 |

| 15 | DLLA150PN315 | 105017-3150 |

| 16 | DLLA151PN086 | 105017-0860 |

| 17 | DLLA152PN009 | 105017-0090 |

| 18 | DLLA152PN014 | 105017-0140 |

| 19 | DLLA152PN184 | 105017-1840 |

| 20 | DLLA152PN063 | 105017-0630 |

| 21 | DLLA152PN077 | 105017-0770 |

| 22 | DLLA153PN152 | 105017-1520 |

| 23 | DLLA153PN177 | 105017-1770 |

| 24 | DLLA153PN178 | 105017-1780 |

| 25 | DLLA153PN203 | 105017-2030 |

| 26 | DLLA154PN005 | 105017-0051 |

| 27 | DLLA154PN006 | 105017-0061 |

| 28 | DLLA154PN007 | 105017-0700 |

| 29 | DLLA154PN0171 | 105017-0171 |

| 30 | DLLA154PN040 | 105017-0400 |

| 31 | DLLA154PN049 | 105017-0490 |

| 32 | DLLA154PN061 | 105017-0610 |

| 33 | DLLA154PN062 | 105017-0620 |

| 34 | DLLA154PN064 | 105017-0640 |

| 35 | DLLA154PN067 | 105017-0670 |

| 36 | DLLA154PN068 | 105017-0680 |

| 37 | DLLA154PN087 | 105017-0870 |

| 38 | DLLA154PN089 | 105017 -0890 |

| 39 | DLLA154PN101 | 105017-1010 |

| 40 | DLLA154PN116 | 105017-1160 |

| 41 | DLLA154PN155 | 105017-1550 |

| 42 | DLLA154PN0171 | 105017-0171 |

| 43 | DLLA154PN185 | 105017-1850 |

| 44 | DLLA154PN186 | 105017-1860 |

| 45 | DLLA154PN208 | 105017-2080 |

| 46 | DLLA154PN270 | 105017-2700 |

| 47 | DLLA154PN940 | 105017-9400 |

| 48 | DLLA155PN046 | 105017-0460 |

| 49 | DLLA155PN053 | 105017-0530 |

| 50 | DLLA155PK107 | 105017-1070 |