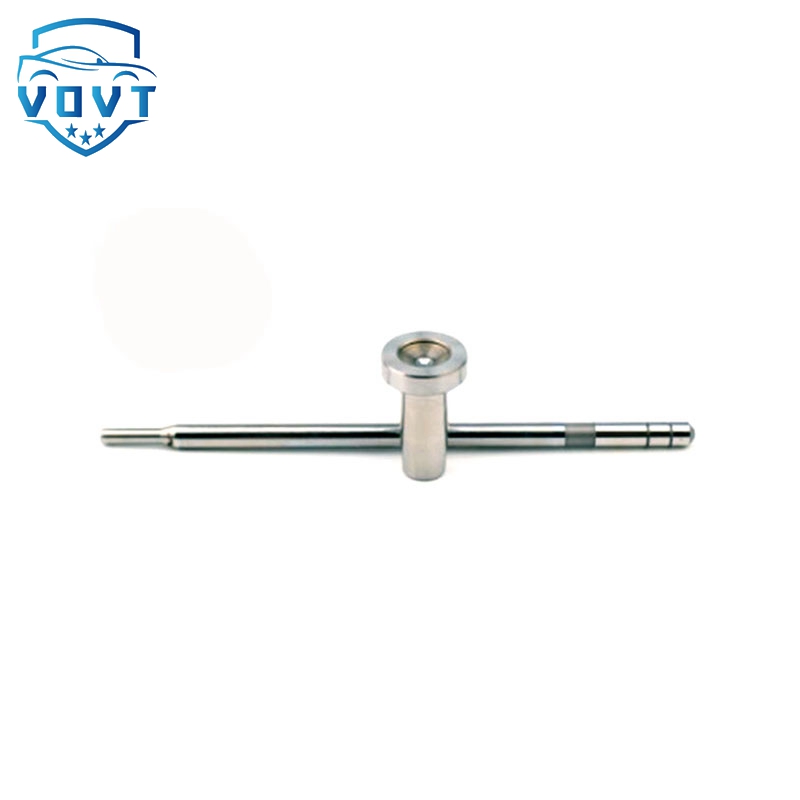

New Common Rail Fuel Injector F00RJ01683 Control Valve Assembly for Injector 0445120080 0445120268

| Produce Name | F00RJ01683 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Numerical analysis and experimental studies on solenoid common rail diesel injector with worn control valve (part1 )

Abstract.

mathematical model of a solenoid common rail fuel injector was developed. Its difference from existing models is control valve wear simulation. A common rail injector of 0445110376 Series (Cummins ISf 2.8 Diesel engine) produced by Bosch Company was used as a research object. Injector parameters (fuel delivery and back leakage) were determined by calculation and experimental methods. GT-Suite model average R2 is 0.93 which means that it predicts the injection rate shape very accurately (nominal and marginal technical conditions of an injector). Numerical analysis and experimental studies showed that control valve wear increases back leakage and fuel delivery (especially at 160 MPa). The regression models for determining fuel delivery and back leakage effects on fuel pressure and energizing time were developed (for nominal and marginal technical conditions).

1. Introduction

Most of modern vehicles with diesel engines are equipped with common rail fuel injection systems. They help to meet strict requirements for exhaust gas emission rates. This is possible due to high fuel pressure generation (until 300 MPa) and use of biodiesel fuel [1-4]. Common rail fuel injectors are the most important components of the system [5]. They allow fuel delivery into cylinders with high accuracy depending on the operating engine mode. There are two types of injectors - with piezo actuators and with solenoid actuators [6-8]. Each of them has some advantages and disadvantages [9]. Regardless of the type of an injector used, high accuracy of fuel delivery must be provided for quite a long period. Technical conditions of a common rail fuel injection system change with an automobile mileage increase [10].