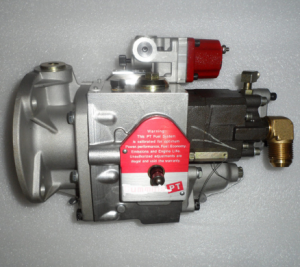

High Quality Common Rail Control Valve Set Assembly F00RJ00447 for Diesel Injector

products detail

Used in Vehicles / Engines

| Product Code | F00RJ00447 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

(1) The speed change of high pressure common rail diesel engine will cause the intake lag, which can not keep up with the fuel injection rate obviously. The matching optimization of intake gas and fuel injection volume is obtained through the main injection volume correction algorithm of speed change, and the appropriate air-fuel ratio is maintained to make up for the hysteresis phenomenon. (2) Multiple injection causes rail pressure fluctuation, which affects the execution accuracy of the main injection amount. The oil injection execution accuracy can be improved by pre-correcting the pulse width of the main injection amount through the correction algorithm of rail pressure fluctuation oil amount. (3) Through the software/hardware control system developed by ourselves, relevant tests are carried out on the engine stand to verify the correctness of the relevant fuel injection control algorithm.

The oxygen content in the air in the plateau area is much lower than that in the plain area, resulting in incomplete combustion in the diesel engine cylinder, which makes the diesel engine appear a series of performance deterioration trends such as power decline, fuel consumption increase, exhaust temperature increase. At present, the study of diesel engine operating characteristics at high altitude mainly adopts one-dimensional simulation or plateau environment simulation bench test method, but the study of flow field in cylinder, oil and gas mixing and combustion mechanism in cylinder is not deep enough. In addition, most of the high altitude power recovery of diesel engines is achieved by studying supercharging system, which greatly improves the adaptability of diesel engines to changing altitude. The disadvantage is that the test period is long and the cost is high. The effect of injection advance Angle on fuel economy, power performance and emission performance of direct injection diesel engine is more significant than other parameters.