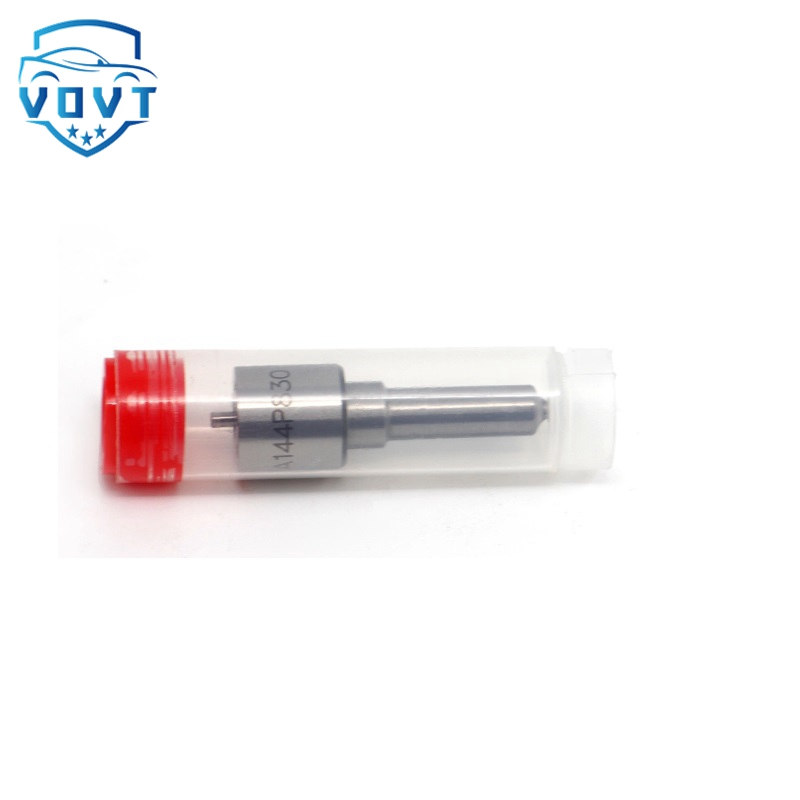

High Quality Common Rail Diesel /Fuel Injector Nozzle DLLA144P830 for Abarth, Toyota

| Produce Name | DLLA144P830 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Analysis of why the injector nozzle stuck in the injectors. (part 4)

The test items that did not meet the design requirements in the data are: 1) The matching gaps of the two steel stamp numbers are greater than the design value;

2) The surface hardness and roughness of the nozzle inner holes of the two steel stamp numbers do not meet the design requirements. The surface hardness of No. HHM is much lower than the design value;

3) The roundness of the needle valve and nozzle of the steel stamp No. HHM exceeds the design requirements;

4) The C and V content of the needle valve materials of the two steel stamps are lower than the national standard requirements, and the initial steel stamp No. HD nozzle C content of 0.20% is slightly higher than the national standard requirements.

5 Conclusion It can be seen from the photo of the stuck needle valve (Figure 2) that thick carbon deposits have formed on the surface of the needle valve, so it can be considered that the matching clearance of the needle valve pair is out of tolerance, and the inclination of the needle valve in the nozzle exceeds Due to the design range, the conical surface at the front end of the needle valve cannot be reliably sealed. high temperature

The high-pressure gas travels retrogradely through the nozzle orifice to the oil cavity of the coupling to generate carbon deposits, which will eventually cause the coupling to stick as the carbon deposits increase. In addition, the surface hardness and roughness of the inner hole of the nozzle did not meet the design requirements, so that the needle valve assembly was more likely to be affected by carbon deposits and cause stagnation.