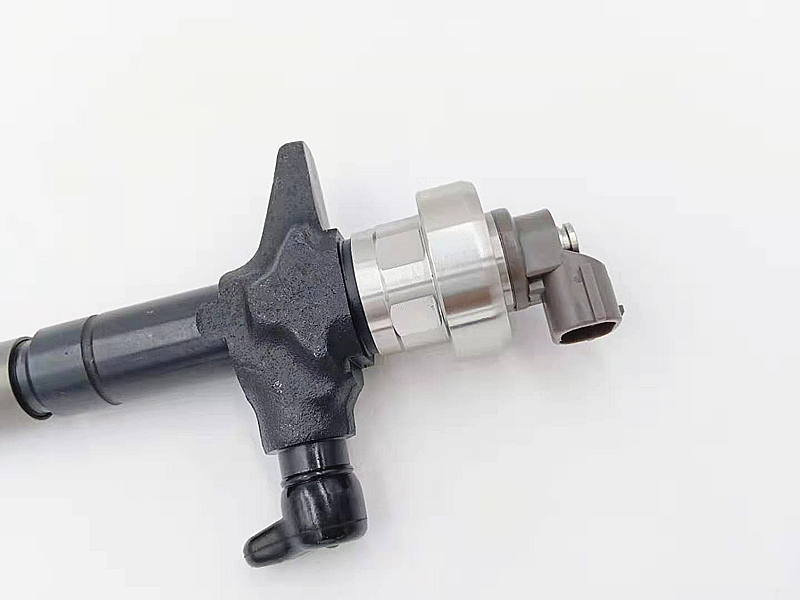

Diesel Injector Fuel Injector 8-98011604-1 Denso Injector for 4jj1

products detail

Used in Vehicles / Engines

| Product Code | 8-98011604-1 |

| Engine Model | 4jj1 |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Atomization performance of automotive fuel injector

The combustion status of an automobile engine directly affects a series of performance indicators such as power performance, fuel economy and exhaust emission characteristics, and the atomization performance of automobile fuel is the key to determining the combustion performance. A better atomization effect can promote more efficient combustion, which plays a very important role in energy saving and air purification. Therefore, it is very important to analyze the working principle of spray atomization, study the physical characteristics and selection methods of spray, and then control combustion to improve engine combustion performance.

Atomization performance of engine fuel

The principle of fuel atomization in the engine is: the pressure nozzle of the fuel injector flows the fuel from the nozzle of the fuel injector into the surrounding gas at high speed so that it breaks up into discrete droplets. After a lot of research and research, it has been shown that when the engine is sprayed, there is not only a process of breaking up the injected fluid (called the first atomization), but the small liquid droplets after the injection will continue to split to form a fine liquid mist (called the first atomization). For the second atomization), these two processes determine the spray characteristics of the engine. Also this process is that the jet stream rupture under the combined influence of the internal and external forces of the liquid is forced by the surface tension of the jetted liquid to form a small sphere, impelling it to have the minimum surface energy of the liquid: the viscosity of the jetted liquid will keep the liquid with of the original shape. The surrounding aerodynamic forces act on the surface of the jetted liquid causing it to break apart. When all the aerodynamic forces combined are greater than all the surface tension forces plus the viscous forces, the liquid will rupture. The surface tension of the liquid and the viscosity of the liquid are the main factors affecting the spray performance. In addition, the design size and dimensions of the nozzle holes as well as the shape of the injected fluid and the injection environment of the liquid all have a profound effect on the atomization performance of the fuel.