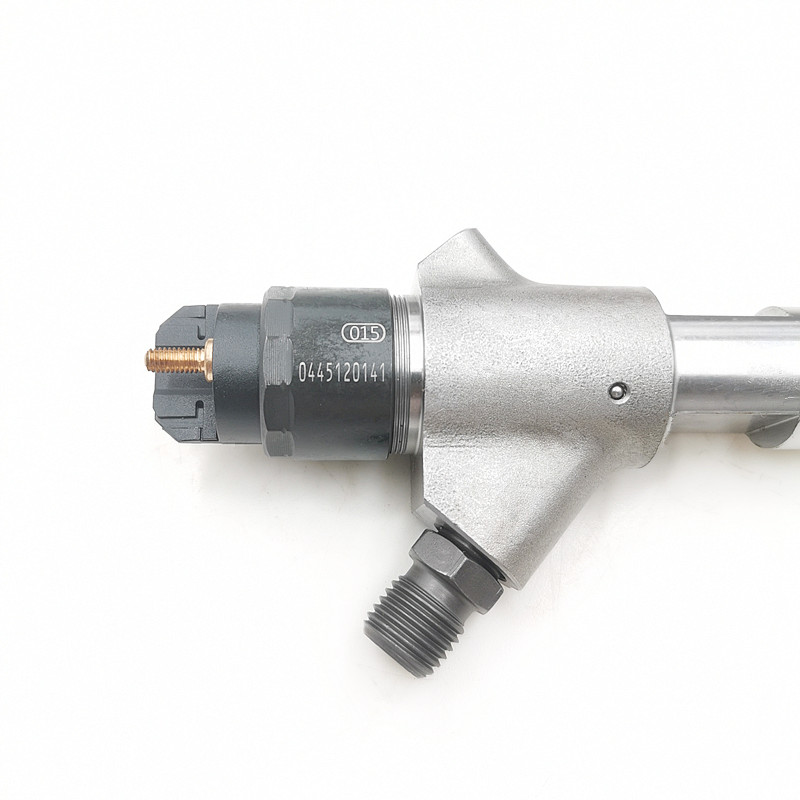

Diesel Injector Fuel Injector 0445120141 Bosch for Gazon Engine D 245.7 E3 Mmz Serie D D 245.30 E3

| Produce Name | 0445120141 |

| Engine Model | GAZon engine D 245.7 E3 MMZ Serie D D 245.30 E3 |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Cavitation Inside High-Pressure Optically Transparent Fuel Injector Nozzles (PART 7)

4 Conclusions (continue)

This approach considered the most common failure mechanisms for brittle materials, and used Finite Element Analysis to resolve the operating loads on the nozzle in detail. The design used sapphire clamps with simple geometries to compress an acrylic nozzle piece in order to minimize the tensile stresses on the inner surfaces of the piece where the pressure from the fuel was applied. For a given pressure capacity, this design is less expensive than one constructed exclusively from sapphire and more durable than one constructed exclusively from acrylic.

The cavitation in the orifices showed dependence on geometry, specifically on the inclination angle of the central axis of the orifice. While cavitation was found on both side of the orifice with the larger inclination angle, it was not due to string cavitation, which is what cavitation in this area has been most commonly attributed to in past studies.

Future work will remove the clearance holes from the sapphire clamps, and instead use simpler sapphire pieces mounted inside stainless steel clamps. This change is expected to reduce the stress concentration in the sapphire pieces and allow greater clamping forces than were possible with the previous design.

The new pieces will be tested to confirm their performance and then experiments will be conducted over a range of back pressures (cavitation umbers) in a pressurized chamber. This will produce a range of cavitating flows for further study.

5 Acknowledgements

The authors would like to thank the EU for supporting this work under the HERCULES-C project, and also to thank the Swedish Energy Agency for their support.

6 References

[1] Soteriou, C., Andrews, R., and Smith, M., 1999, “Further Studies of Cavitation and Atomization in Diesel Injection,” (724).

[2] Arcoumanis, C., Flora, H., and Gavaises, M., 2000, “Cavitation in Real-Size Multi-Hole Diesel Injector Nozzles,” (724).

[3] Reid, B. a., Hargrave, G. K., Garner, C. P., and Wigley, G., 2010, “An investigation of string cavitation in a true-scale fuel injector flow geometry at high pressure,” Phys. Fluids, 22(3), p. 031703.

[4] Badock, C., Wirth, R., Fath, A., and Leipertz, A., 1999, “Investigation of cavitation in real size diesel injection nozzles,” Int. J. Heat Fluid Flow, 20(5), pp. 538–544.

[5] Blessing, M., König, G., Krüger, C., Michels, U., and Schwarz, V., 2003, “Analysis of Flow and Cavitation Phenomena in Diesel Injection Nozzles and I ts Effects on Spray and Mixture Formation.”

[6] Butcher, a. J., Aleiferis, P. G., and Richardson, D., 2013, “Development of a real-size optical injector nozzle for studies of cavitation, spray formation and flash-boiling at conditions relevant to direct-injection spark-ignition engines,” Int. J. Engine Res., 14(6), pp. 557–577.

[7] Mitroglou, N., McLorn, M., Gavaises, M., Soteriou, C., and Winterbourne, M., 2014, “Instantaneous and ensemble average cavitation structures in Diesel micro-channel flow orifices,” Fuel, 116, pp. 736–742.