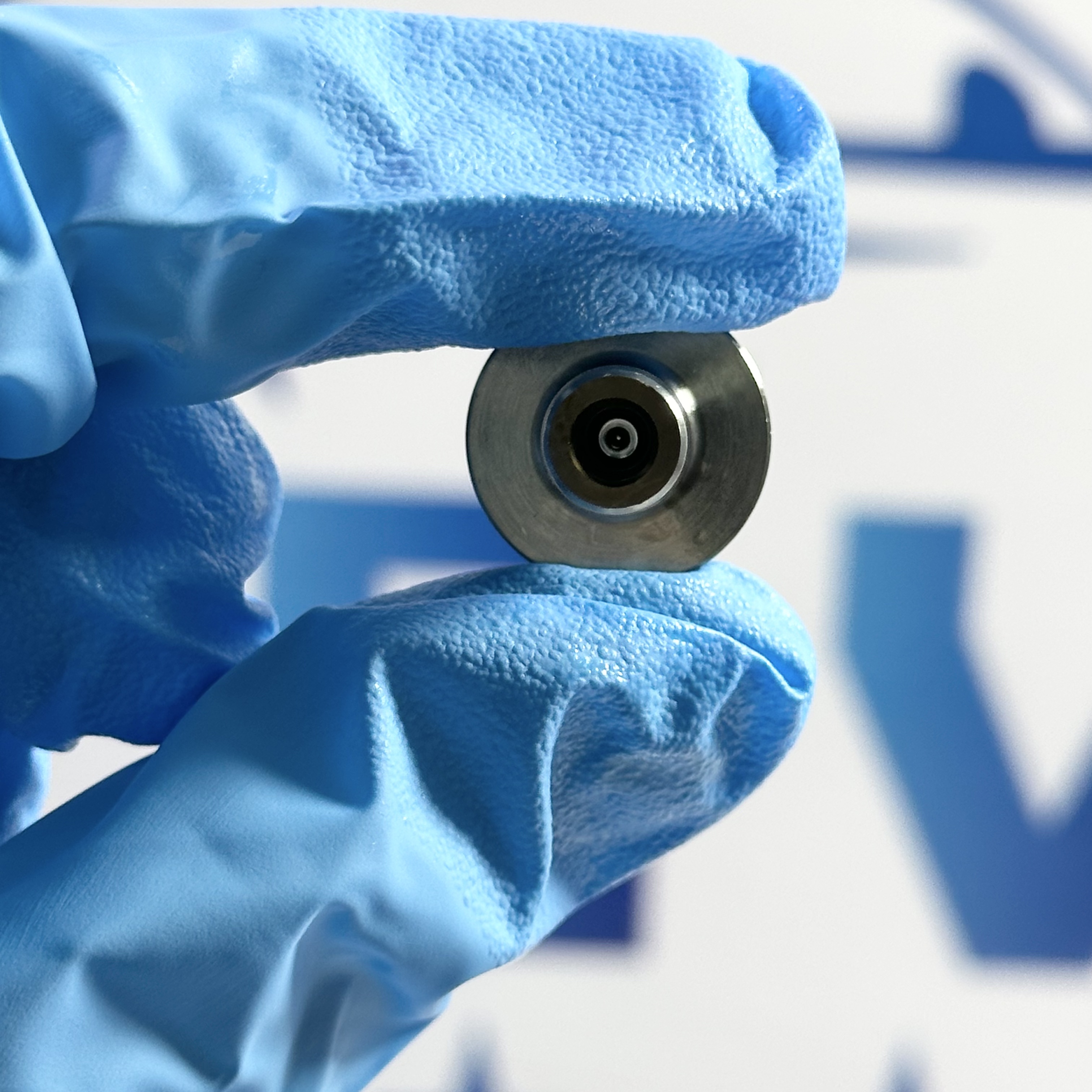

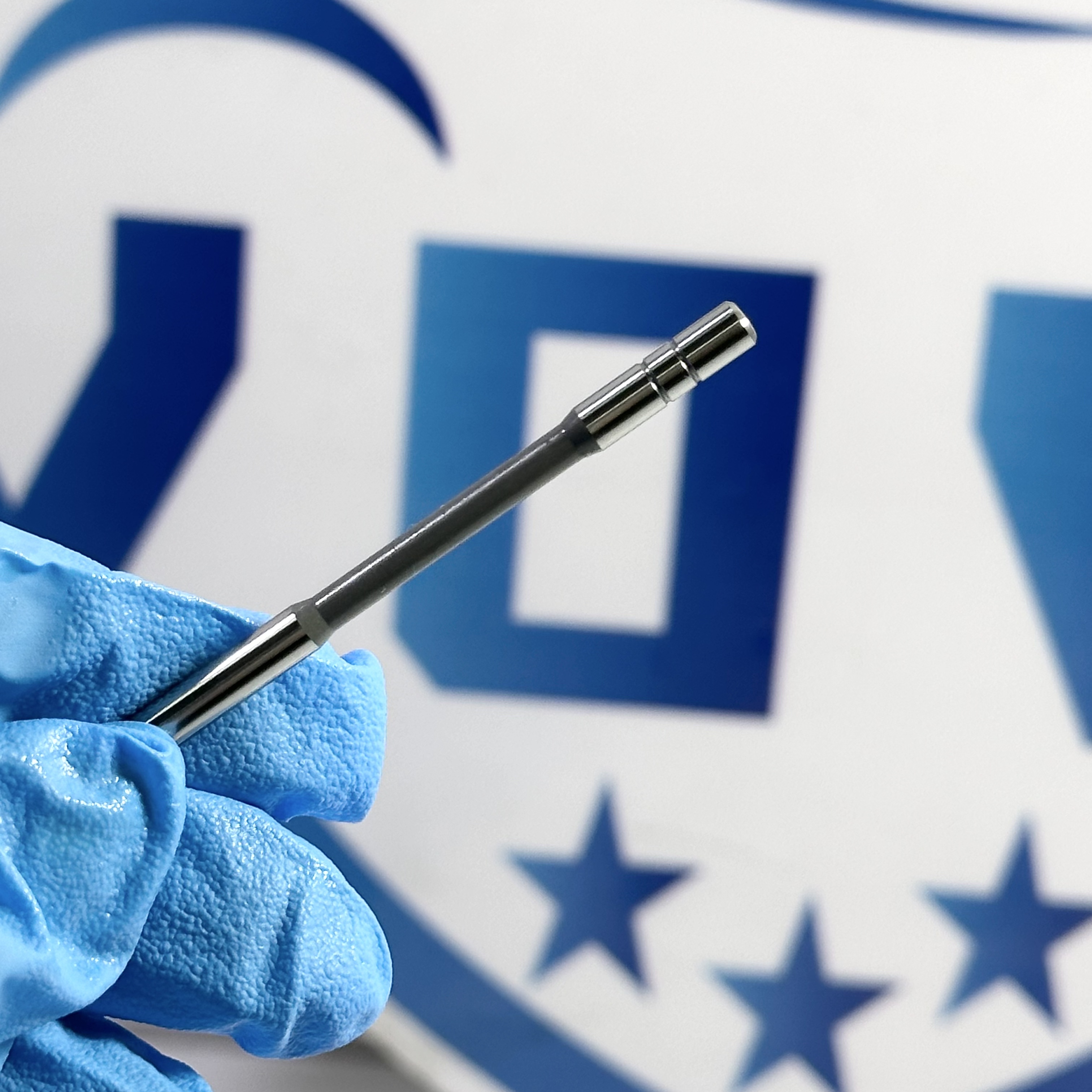

High Precision New Diesel Injector Control Valve F00RJ02410 Valve Assembly for Fuel Injector Engine Spare Parts

Products Description

| Reference Codes | F00RJ02410 |

| Application | / |

| MOQ | 6 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Mechanism of the Influence of Micro-Gap Flow on the Leakage Characteristics of Valve Assemblies

Abstract

Valve assemblies are critical components in hydraulic and fuel injection systems, where sealing performance directly affects pressure stability and system efficiency. Due to unavoidable manufacturing and assembly tolerances, micro-gaps often exist between the valve spool and sleeve, leading to fluid leakage. Although leakage volumes are usually small, they can accumulate and cause performance deterioration under long-term operation. This paper investigates the fundamental characteristics of micro-gap flow and analyzes its influence on the leakage behavior of valve assemblies, providing insights for structural optimization and reliability enhancement.

1. Introduction

Under high-pressure operating conditions, valve assemblies must ensure both fast dynamic response and reliable sealing. However, micro-gaps between moving pairs inevitably result in leakage, which not only reduces volumetric efficiency but may also induce pressure fluctuations and premature wear. Therefore, understanding the mechanism of micro-gap flow and its impact on leakage characteristics is essential for improving valve performance.

2. Characteristics of Micro-Gap Flow

The fluid flow in micro-gaps is typically characterized by low Reynolds numbers, dominated by viscous effects. It can be approximated as Poiseuille-type laminar flow, where leakage rate is proportional to the cube of the gap height. Consequently, even micron-scale variations in clearance can significantly affect leakage volume. In addition, fluid viscosity, pressure gradients, and temperature conditions further modify flow resistance and leakage behavior.

3. Leakage Mechanism Analysis

The leakage mechanism of valve assemblies is influenced by several key factors:

-

Gap size: Leakage flow increases exponentially with clearance size, making it the most critical parameter.

-

Pressure differential: A higher pressure drop accelerates fluid through the micro-gap, resulting in greater leakage.

-

Surface roughness: Microscopic asperities alter the effective flow channel, potentially inducing local turbulence and amplifying leakage.

-

Fluid properties: High-viscosity fluids reduce leakage but increase energy loss, whereas low-viscosity fluids leak more readily.

4. Engineering Optimization Strategies

To mitigate leakage in valve assemblies, the following measures can be considered:

-

Precision machining and surface finishing to minimize clearance tolerance and improve surface quality.

-

Optimized valve spool and sleeve geometry to achieve uniform pressure distribution across the gap.

-

Application of advanced surface coatings or composite materials to enhance wear resistance and delay clearance growth.

-

Integration of CFD simulations with experimental validation to predict leakage behavior under various operating conditions.

5. Conclusion

Micro-gap flow is the fundamental cause of leakage in valve assemblies, governed by the interaction between clearance geometry, pressure conditions, and fluid properties. By controlling clearance accuracy, optimizing structural design, and employing advanced surface treatments, leakage levels can be significantly reduced, thereby improving reliability and extending the service life of valve assemblies.