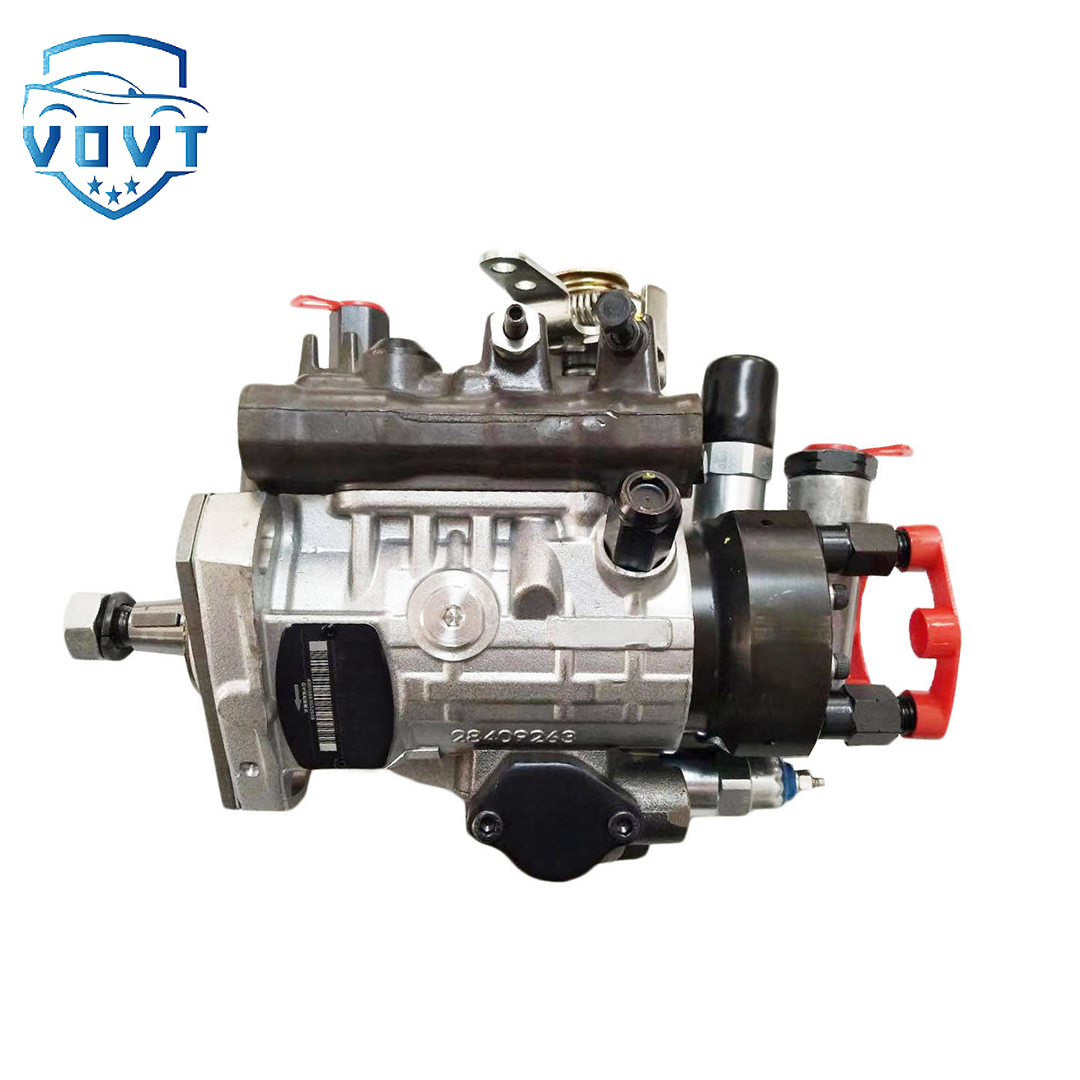

High Performance Fuel Injection Pump 9520A413G Diesel Injection Pump for Perkins Vista 1104D Delphi

products description

| Reference Code | 9520A413G |

| MOQ | 1 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

the common methods for diesel engine fault diagnosis

1. Observation method: Determine the fault situation by observing the fault characteristics such as the exhaust smoke color of the diesel engine.

2. Auscultation method: Use hearing to determine the nature of the fault location and the degree of damage based on the abnormal sound of the diesel engine.

3. Comparison method: For some assemblies or parts, use replacement parts comparison method to determine whether there is a fault.

4. Cylinder cutting method: Stop the operation of a certain cylinder to determine whether the fault occurs in that cylinder. The cylinder cutoff method generally stops the oil supply to the cylinder that is suspected to be faulty, and compares the state changes of the diesel engine before and after the cylinder cutoff to narrow down the scope of further finding the fault location or cause. It is worth noting that unlike the mechanical fuel injection system, the electronically controlled common rail fuel injection system cannot cut off the fuel by loosening the high-pressure oil pipe, but must disconnect the fuel injector harness.

5. Fault light diagnosis method: When the machine fails, you can read the flash code through the flash code light on the vehicle dashboard, and refer to the flash code table to initially determine the cause of the error.

6. Special diagnostic equipment: Use the diesel engine manufacturer's special fault diagnosis equipment to make a comprehensive and systematic judgment on the diesel engine.

All of the above methods can be used to diagnose diesel engine faults, but when performing fault diagnosis, the corresponding operating specifications and safety precautions must be strictly followed to ensure the safety of personnel and equipment.