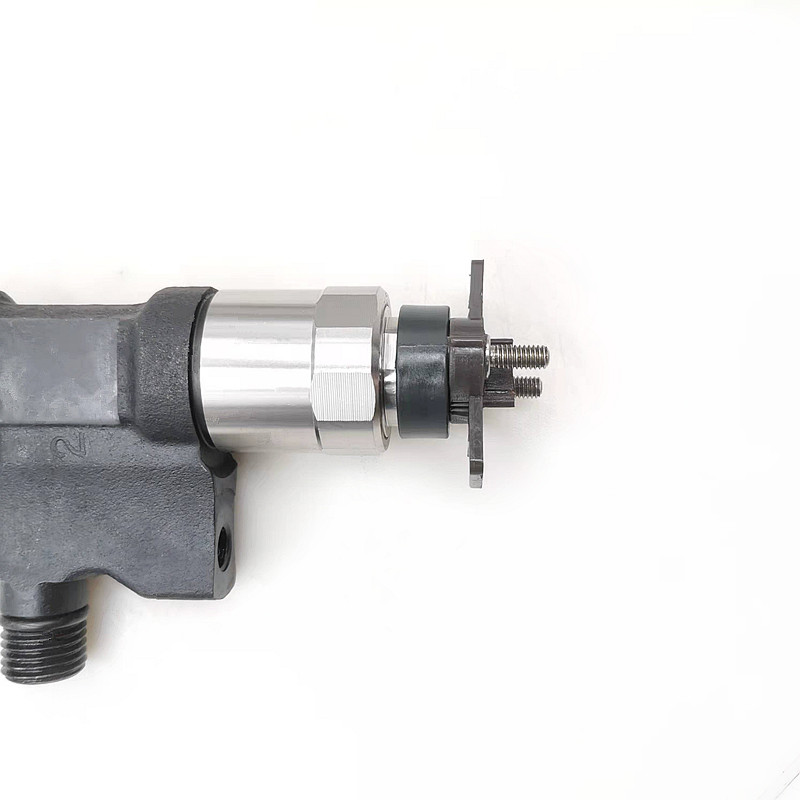

Diesel Injector Fuel Injector 095000-8903 Denso Injector for Isuzu/Hitachi HP3 / Cdi, Isuzu N-Series 4HK1 5.2 D, Isuzu N-Series 6HK1 7.8 D, Isuzu F Series 6HK

products detail

Used in Vehicles / Engines

| Product Code | 095000-8903 |

| Engine Model | 4HK1 / 6HK1 |

| Application | Isuzu/Hitachi HP3 / CDI |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

But because the gap is small, in the range of 0.01 ~ 0.02mm, so at the beginning of the injection stage, due to the needle valve throttling effect is large, the injection of high pressure fuel less, as the needle valve continues to rise, the annular gap channel is also increasing, the needle valve throttling effect is significantly reduced, the injection of high pressure fuel will increase.

The power and economy of a diesel engine depend on the state of fuel injection into the combustion chamber. In order to make full combustion, the fuel injected into the combustion chamber should meet the following two conditions: First, in order to make the fuel combustion, the fuel should be quickly evaporated into fuel steam. In order to promote the evaporation of fuel, fuel atomization should be made, increase the surface area, and the surrounding air is a good exchange of heat and quality. Second, in order to make the fuel steam and air can be very good mixing, perfect combustion organization, should be sent to the fuel steam to every corner of the combustion chamber. The former is the atomization characteristics of the spray, the latter is the distribution characteristics and penetration. Fuel atomizing injector into the combustion chamber of fuel into fine oil particles, that is, into the fog of the process called atomization. Due to the viscosity and pressure of the fuel, the liquid fuel is ejects from the annular gap between the inverted cone or conical part of the head of the needle valve and the jet hole in a cylindrical shape. When the jet leaves the jet hole, it gradually disperses into a group of particles, which generates a conical spray on the macro level. Fuel oil atomization methods vary according to the use, atomization methods can be summarized as pressure atomization, two-fluid atomization, centrifugal atomization, vibration atomization and many other methods.