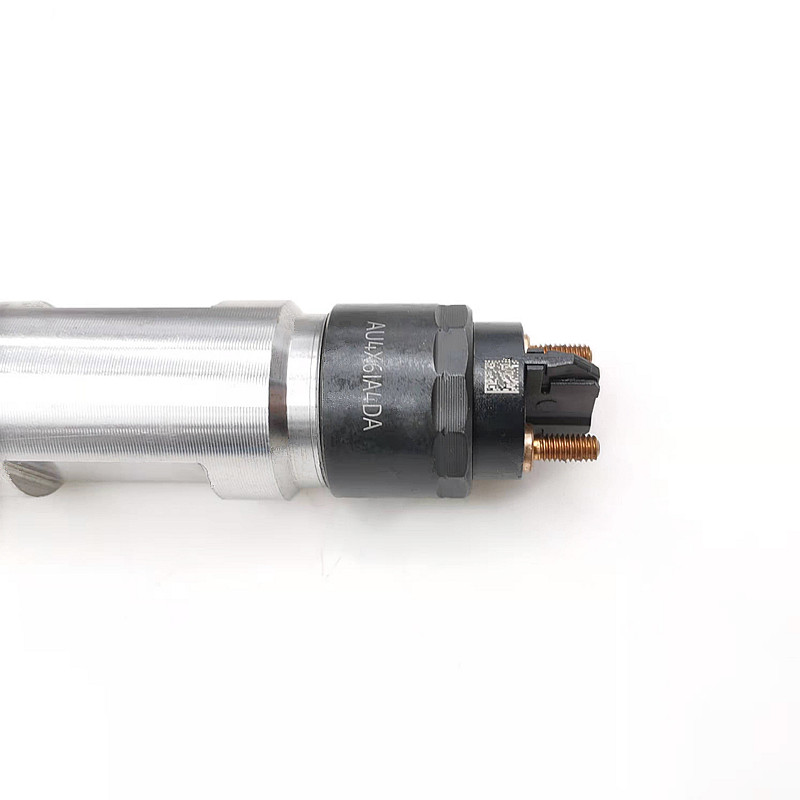

Diesel Injector Fuel Injector 0445120355 Bosch for MAN TRUCK/BUS

| Produce Name | 0445120355 |

| Engine Model | / |

| Application | MAN TRUCK/BUS |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Injector Inspection - Injector Tips

(1) Use a magnifying glass to check the nozzle hole of the fuel injector and the end of the nozzle head, and compare them with the new nozzle head. The fuel injector head should be discarded if it has any of the following conditions:

1 Abrasive wear, this kind of wear will occur inside the injector head, therefore, both the inner and outer sides should be inspected.

2 There are corrosion, ablation damage and overheating, which are usually caused by high water, acid and sulfur content in the fuel or due to overload work.

3 The spray hole is enlarged or deformed, which is caused by cleaning the spray hole with a drill or other tools and using it for too long. Note that the size of the nozzle hole of the injector head must not be changed. (2) Check the shape of the plunger contact surface on the nozzle head. Choose a new plunger and paint it Prussian blue. Insert the plunger into the injector tip and turn it 90°. Injectors can be reused if the plunger contact surface is continuous and occupies 40% of the area around the injector tip cone or plunger bore. At the same time, the plunger must be in contact with the cone area from 1/4 to the entire cone area on the nozzle head. Nozzle tips with a contact surface below 1/4 of the nozzle tip end area cannot be used. If the contact surface of the injector tip is at the end, its contact area must be greater than 1/2 cone surface area. Use the tester to check the oil leakage of the injector and plunger. 3) Check the damage and unevenness of the end plane of the plunger sleeve of the injector head. Check the unevenness of the surface with a flat plate (preferably a ground plate) and "blueing agent". If the nozzle head is found to be damaged or uneven, mark it for repair.

(4) The fuel injector can be inspected by spraying on a special maintenance tool. This tool can be used to check the injector tip before it is installed on the injector.