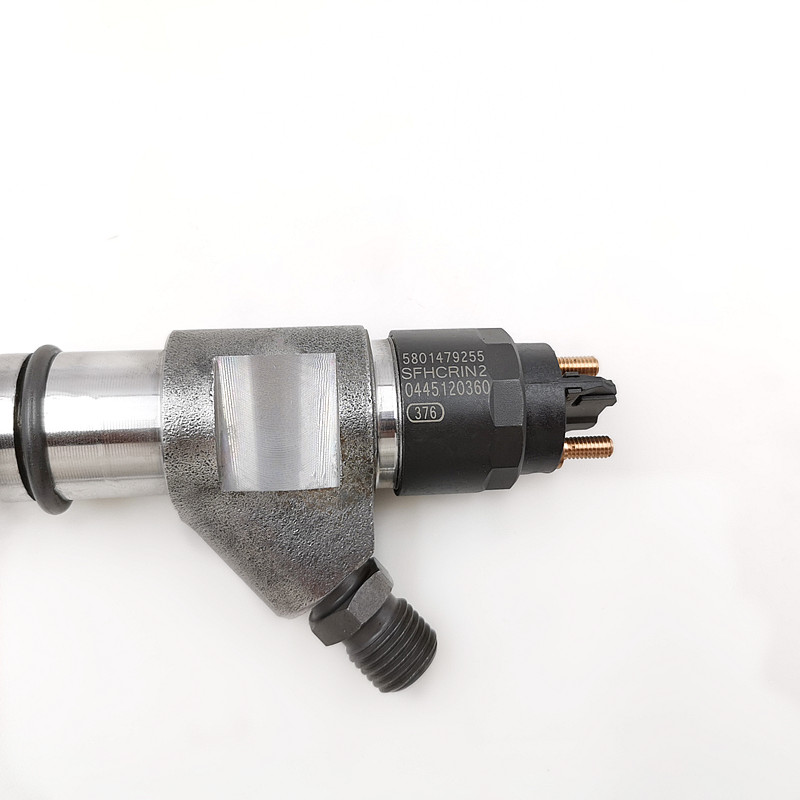

Diesel Injector Fuel Injector 0445120360 Bosch for SFH Isuzu Diesel Engine

| Produce Name | 0445120360 |

| Engine Model | SFH Isuzu Diesel Engine |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Dealing with the main injector problems

Among the many failures of the injector, the failures caused by the damage of the needle valve assembly and the damage of the injection hole account for the vast majority according to statistics. Therefore, we should focus on the maintenance methods and measures for the needle valve assembly and the nozzle hole 3.1 Maintenance of the needle valve assembly

If there is stagnation in the needle valve and the needle valve body, or slight ablation and wear on the sealing cone surface of the needle valve, it is necessary to grind the needle valve couple. Try not to slap the valve seat when grinding to reduce the wear of the valve seat. You can grind it manually or by clamping the handle of the needle valve on a bench vise with a soft metal protection port.

After the wear between the needle valve and the needle valve seat, the valve seat can be ground to ensure the sealing performance. When grinding, a small amount of abrasive can be applied to the sealing surface of the needle valve cone surface. Be careful not to stick abrasive to the guide when inserting the needle valve to avoid excessive wear on the guide. Grind with abrasive until finally, you can use clean lubricating oil for grinding, until the sealing cone surface has an obvious ring with a width of 0.20~0.25mm, and the sealing performance meets the requirements.

After the needle valve is overhauled, it can be soaked in clean diesel oil at 70~80C for about 10 minutes, and then clean the needle valve assembly with clean diesel oil to remove internal debris. The needle valve is a precision coupling, and it should be handled with care during maintenance, and it must not touch hard objects, otherwise its scratches may lead to the direct scrapping of the coupling. The maintenance of the needle valve coupler can solve such problems as the seal failure of the needle valve coupler, the needle valve stuck, and so on. If the fuel injector does not meet the necessary technical requirements after inspection, it must be replaced with a new one.