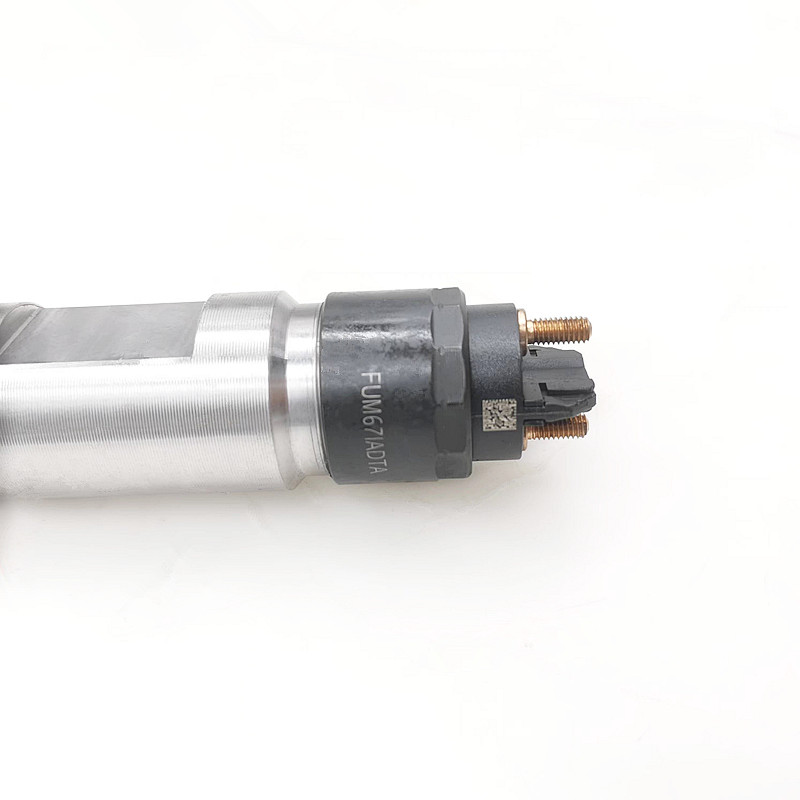

Diesel Injector Fuel Injector 0445120311 Bosch for Man Tgx 18.440 / 24.440 / 26.440 12.4 L D2676 I6 (Turbocharged)

products detail

Used in Vehicles / Engines

| Product Code | 0445120311 |

| Engine Model | / |

| Application | Gaz Deutz Yamz Engine |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

| Delivery Method | DHL, TNT, UPS, FedEx, EMS or Requested |

Mechanism of injector carbon deposit formation part2

- 3) From the perspective of the thermal oxidation process of diesel engines, Singer et al. used pure diesel oil samples for heat treatment, studied the influence of temperature and time on the formation of carbon deposits in the thermal oxidation reaction of diesel oil, and believed that the formation of carbon deposits largely depends on the temperature at which diesel is exposed , and the formation process of carbon deposits is divided into the following two stages: 1) When the diesel oil exposure temperature is higher than 140C, after heating in the air for a long time, the diesel oil degrades and decomposes, and a part of it forms high molecular weight oxidized diesel products (High Molecular Weight Oxygenated Fuel Products, MOFP), at this time MOFP can further oxidize with the evaporated diesel, and may be taken away by clean diesel; when the diesel exposure temperature is lower than 140C, even if it is continuously heated in the air for several hours, No obvious MOFP formation 2) When MOFP is heated to 150C, MOFP begins to form bifurcated high molecular weight substances. When the heating time is short, most of the substances will still be taken away by diesel oil; as the heating temperature increases As the temperature increases and the heating time prolongs, the MOFP increases continuously, and when the critical temperature reaches 300C, most of the material forms an insoluble and interconnected polymeric network, and finally forms carbon deposits.

4) 4) From the perspective of adding zinc element, Ikemoto et al. [0] proposed the formation mechanism of carbon deposit inside the nozzle hole of the fuel injector when zinc element was added to diesel, and believed that when diesel oil containing zinc element was used, the formation process of carbon deposit in the nozzle hole could be It is divided into three stages, as shown in Fig. 2: (1) In the initial stage, since the outlet of the nozzle hole is close to the combustion gas, the temperature is higher, so more carbon deposits are formed, while the inlet temperature of the nozzle hole is lower, and the carbon deposits are less. Zinc reacts with a small amount of anteline acid in the combustion gas to form zinc antelope, which forms a bottleneck at the outlet of the injection hole, restricting the flow of diesel; The carbon deposit at the inlet of the nozzle hole forms zinc carbonate, and the zinc anteline at the outlet of the nozzle hole gradually reaches saturation (the zinc carbonate decomposes as the temperature rises), and the carbon deposit gradually develops towards the middle and the inlet side of the nozzle hole; (3) saturated state , the zinc carbonate at the inlet of the nozzle hole gradually reaches saturation, and forms a bottleneck at the outlet of the nozzle hole, at this time a balance is reached between the formation and removal of carbon deposits.

Write your message here and send it to us