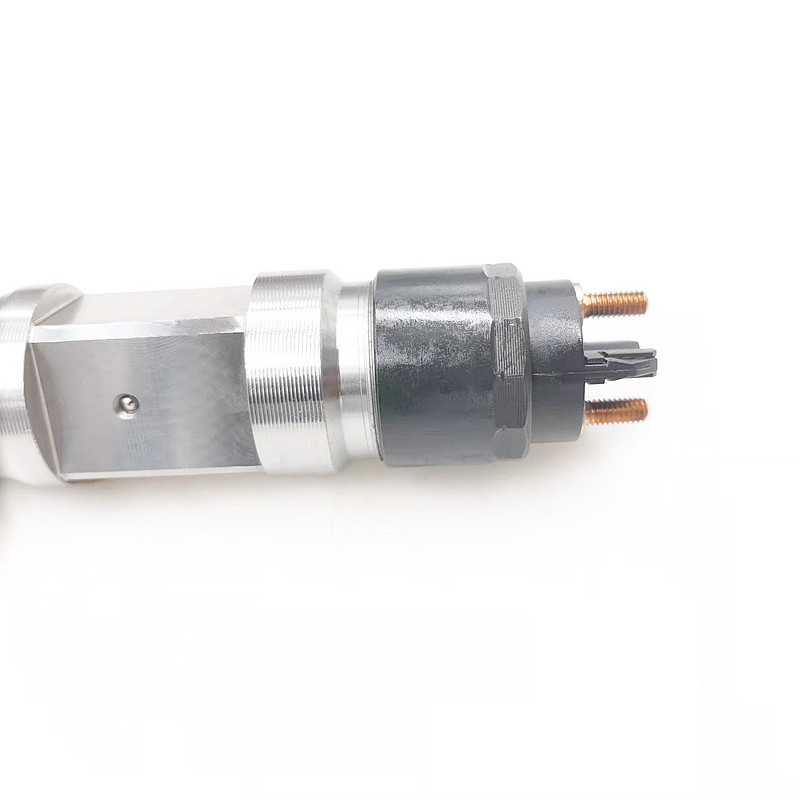

Diesel Injector Fuel Injector 0445120312 Bosch for Man Truck/Bus Engine

products detail

Used in Vehicles / Engines

| Product Code | 0445120312 |

| Engine Model | / |

| Application | Gaz Deutz Yamz Engine |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

| Delivery Method | DHL, TNT, UPS, FedEx, EMS or Requested |

Our advantage

- 1 Competitive price

- 2 Ready stock

- 3 Fast delivery

- 4 100% tested before shipped

- 5 Small order allowed

Methods to Solve Diesel Engine Fuel Injector Faults

Some small negligence of users in the process of using and maintaining diesel engines may lead to major failures, emphasizing the matters that should be paid attention to when using and maintaining fuel injectors. Once the fuel injector of a diesel engine fails, maintenance personnel must perform "4-R" processing on several failed parts, that is, dismantling, repairing, remodeling, and replacing 4 procedures. If the performance of the diesel injector is difficult to meet the set requirements, it is necessary to adopt a systematic and scientific troubleshooting method to accurately find the root cause of the failure and formulate effective solutions. There are two most commonly used methods when solving diesel injector failures: one is the active method, which can quickly identify the root cause of diesel injector failure while the performance of the components of the diesel injector is declining; The other is preventive maintenance. Compared with active maintenance, preventive maintenance has the characteristics of non-destructive maintenance, and maintenance is carried out on the basis of not affecting the normal operation of agricultural machinery. This kind of maintenance can be mainly divided into three categories: the first category, regular maintenance and maintenance of the working subsystems, mechanical devices and various parts; the second category, check whether the spare parts are damaged, and repair them if necessary and replacement; the third category is timely replacement of severely damaged parts.

Diesel injector: 1-nozzle; 2-tight cap; 3-spring; 4-injector body; 5 and 17-O-ring; 6-pressure adjusting screw; 7-nut; 8-cotter pin; 9 and 15-double ear stop washer; 10-jack; 11-pin; 12-needle valve; 13-connecting ring; 14-screw; 16-injector connector