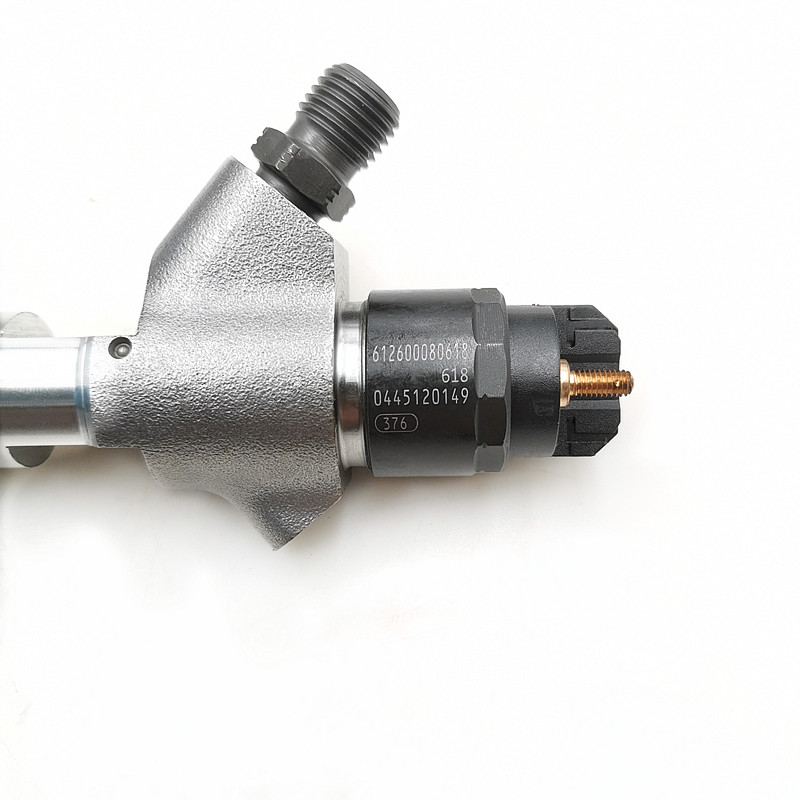

Diesel Injector Fuel Injector 0445120149 Bosch for Longgong855 Forklift Engine Weichai Wd10

| Produce Name | 0445120149 |

| Engine Model | WEICHAI DW10 |

| Application | LONGGONG 855 Forklift |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL,as your preference |

Effect of Double Injector on Combustion Process in a 396 Series Diesel Engine (part 5)

When the 8-hole injector is adopted, the impact of the reduced penetrating distance on the combustion process is intensified, the total fuel distribution area and the pre-mixed combustion are reduced, and the diffusion combustion is decelerated, thus making the combustion incomplete and thermal efficiency lower. After the 4-hole dual-injector is adopted, as the two injectors are separated by a certain distance, the spatial distribution area of the fuel is widened, and the mixing effect between fuel spray and air in cylinder is intensified.

Although the penetrating distance is still shorter and the pre-mixed combustion is still less than that of the 5-hole injector, the accumulated heat release is equivalent to that of the 5-hole injector because the air in cylinder is fully utilized, the combustion duration of diffusion combustion is slightly longer and the combustion is more complete. Figure 5 shows that, when the 8-hole injector is adopted, the combustion is incomplete, the combustion pressure and average temperature in cylinder and the NO emission are lower. When the 4- hole dual-injector is adopted, the NO emission is about 60% of that of the 5-hole injector due to the low maximum combustion temperature.

4 Simulation results and analysis of shortening injection duration of the 4-hole dual-injector

Under the condition that the injection duration and the effective flow area are unchanged, the thermal efficiency is reduced when changing the 5-hole injector to the 8-hole injector. However, if the 4-hole dual-injector is adopted, the thermal efficiency is kept the same as that of the 5-hole injector. If the injection pressure is increased, the injection duration is shortened and the penetrating distance of oil beam is increased, the mixing of fuel and air is further increased and the combustion process is improved. Figure 6, Figure 7 and Figure 8 respectively show the pressure in cylinder, heat release rate, average temperature in cylinder, accumulated heat release and NO mass fraction when the injection angle of the 4-hole dual-injector is 26.84°CA, 22°CA and 20°CA.