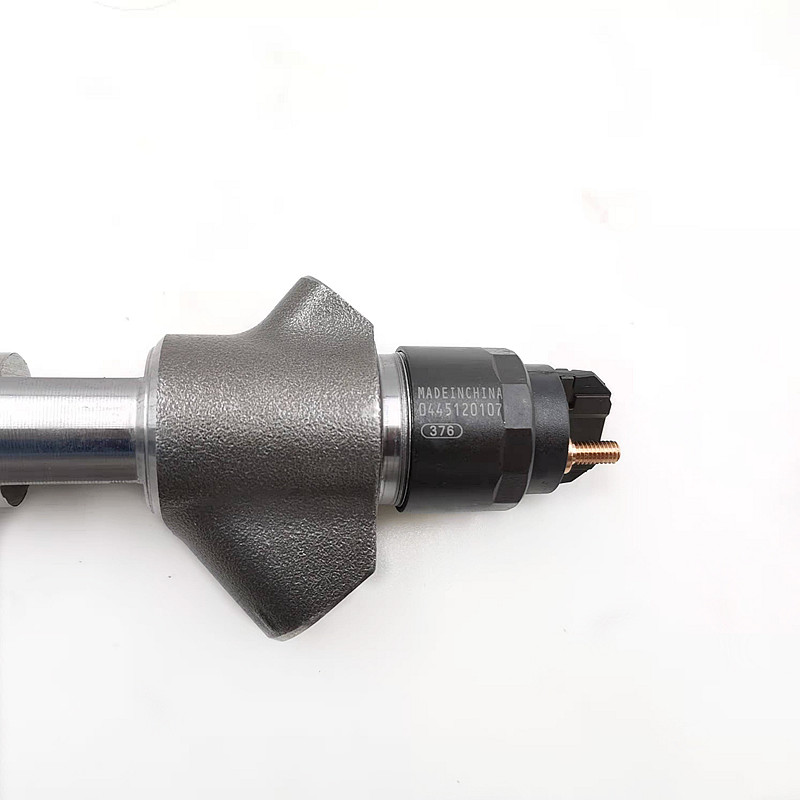

Diesel Injector Fuel Injector 0445120107 Bosch for Nbe 6.2 Wdew (WEICHAI POWER CO.)

| Produce Name | 0445120107 |

| Engine Model | NBE 6.2 WDEW (WEICHAI POWER CO.) |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Bosch's latest fuel injector technology

1. Reduce the flow rate of the fuel injector. Same as Denso's development strategy, Bosch is also developing high-pressure injectors to reduce the flow rate of injectors. The purpose of this is to reduce fuel consumption and NO. emissions (reduce combustion temperature) at the same time, but this will have a side effect, which is to increase noise, so the second technology described below is required to compensate for the increase in noise.

2. Digital Waveform Technology (DRS, Digital Rate Shape) This technology has gone through 2 generations. The first generation of DRS was first used on the CRI2-20 injector, which makes the pre-injection and main injection with the help of CRI2-20 enhanced solenoid valve The injection interval is reduced to 0.2 ms, and the pre-injection amount is precisely controlled at 1.5 mg/str. The advantage of this is that the ignition time of the pre-injection is delayed, making the pre-injection closer to the main injection, which is conducive to the rapid combustion of the main injection !0. The difference between the second generation DRS strategy and the first generation is that it can be digitally simulated to achieve the shape of the continuous slope and can increase the mass fraction and raw NO. Injection plus main injection (divided into 2 parts, up to 3 parts) to limit the amount of ready fuel for ignition delay, and limit the heat release to a certain level so that the smoke (soot value) can be reduced to a certain basic level. There is a significant decrease

3. Closed-loop control. Similar to Denso's iart technology, Bosch plans to install a pressure measurement unit on its CRI2-20 and later products and all CRI3 products to achieve closed-loop control.