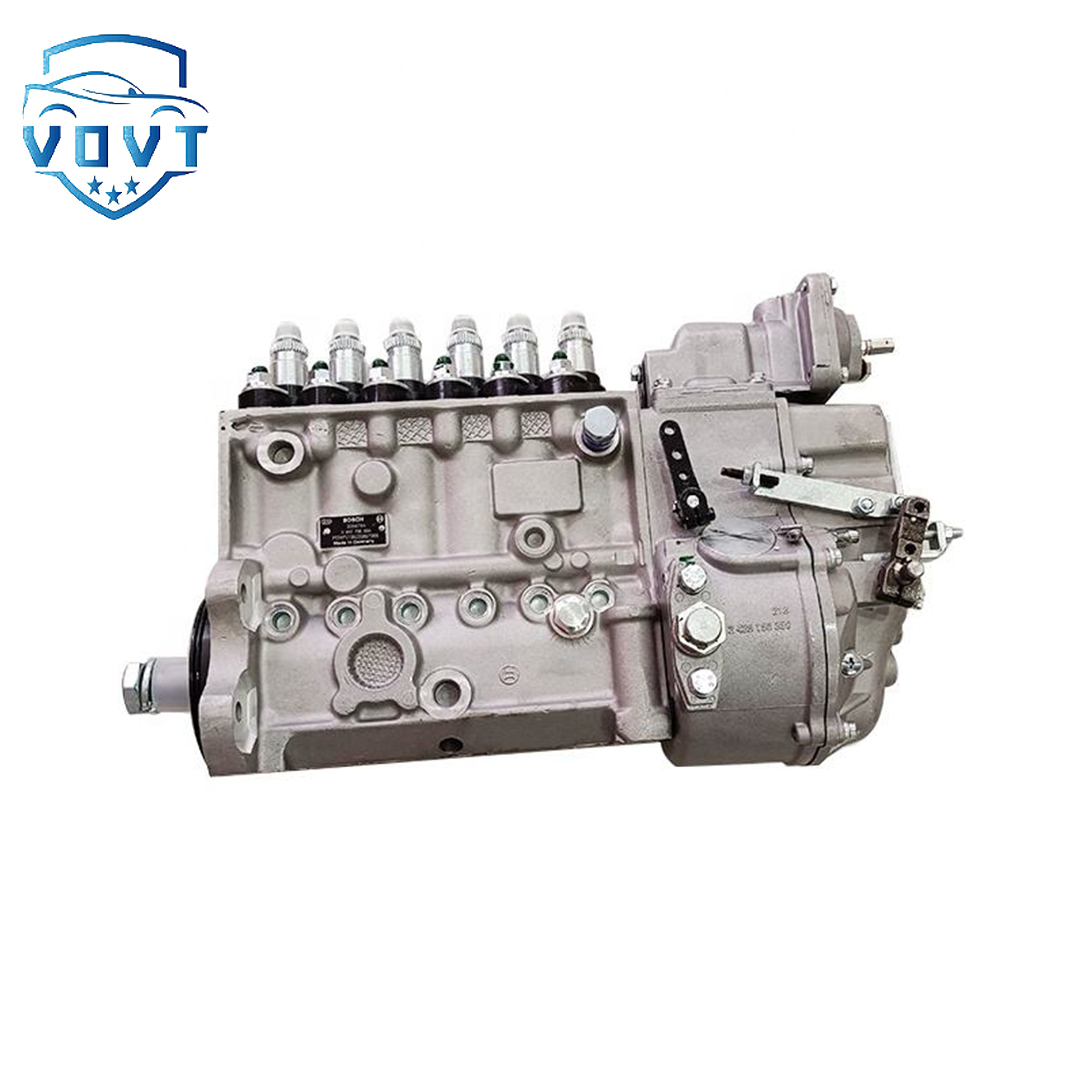

4945791 Diesel Fuel Pump Common Rail High Pressure Fuel Pump for Engine Parts

products description

| Reference Code | 4945791 |

| MOQ | 1PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Fuel pump installation methods and precautions

Installation method and sequence of fuel pump:

1. Place the unit on the foundation with embedded anchor bolts, and use pairs of wedge pads between the base and the foundation for calibration.

2. Loosen the large coupling shaft, use a level to place it on the pump shaft and base respectively, adjust the wedge pad to correct the level of the unit, and tighten the anchor bolts appropriately to prevent movement.

3. Correct the concentricity of the pump shaft and the motor shaft. On the outer circle of the coupling road, the allowable deviation is 0.1 mm; the gap between the two coupling planes should be guaranteed to be 2 to 4 mm (the smaller value is taken for the smaller pump). The gap should be uniform. The tolerance is 0.3 mm.

4. After connecting the pipeline and determining the rotation direction of the motor, connect the coupling and check the concentricity of the shaft again.

5. After the actual trial operation of the unit for 2 to 3 hours, make a final inspection. If there are no adverse phenomena, the installation is deemed to be qualified. During the trial operation, check the temperature and vibration of the bearings as follows: imported pump valve

6. During the installation process, all holes in the unit should be covered to prevent debris from falling into the machine.

7. In order to prevent debris in the pipeline from entering the pump, for newly installed pipelines, a filter should be installed on the pump glue, and its effective cross-section should be 2 to 3 times larger than the cross-section of the suction pipe. Imported pump.

Things that should be paid attention to during the installation process of fuel pump:

1. The quality of the fuel pump installation has a very important impact on the smooth operation and service life of the pump. Therefore, the installation and correction work must be carried out carefully and not hastily.

2. The installation height, length and diameter of the fuel pump suction pipe should meet the calculated values, strive to be brief, and reduce unnecessary losses (such as elbows, etc.); and ensure that the allowable cavitation margin is not exceeded when the pump is working.

3. The suction and discharge pipes of the fuel pump should have brackets. The pump is not allowed to bear the load of the pipeline.

4. The location where the fuel pump is installed should be spacious enough to facilitate maintenance work.