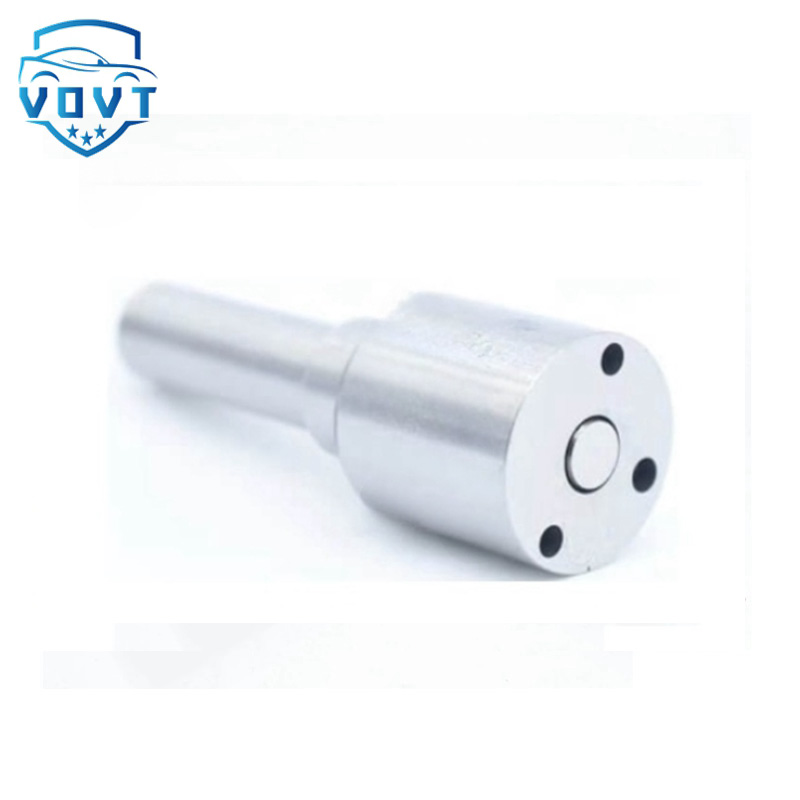

New 100% Tested Common Rail Diesel /Fuel Injector Nozzle DLLA155S295c2

| Produce Name | DLLA155S295c2 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

The dismantling process of the injector nozzle pair (part 3)

If the valve line of the needle valve and the injector body is uneven, it can be forced to cooperate by knocking and stamping. Put the needle valve dipped in some oil into the fuel injector body, put a plunger chip on the needle valve handle, and lightly hit a dozen hammers with a half-pound hammer to prevent the needle valve and the fuel injector body from being knocked hard. If the wire is damaged, turn it 90° and knock again, and turn it three times in total to achieve a good fit.

There are signs of damage to the injector body valve wire and needle valve wire. If the damage marks are large, apply a small amount of coarse abrasive paste to the valve line of the needle valve head, and clamp the needle valve handle to the special disassembly tool for impact and rotary grinding. If you have a bench drill or a hand drill, you can install the needle valve handle on the chuck and turn it for grinding, but the speed should not be too fast, so as to prevent the valve line from being difficult to restore smoothness due to quick grinding.

When grinding, you should pinch the injector body with your hands and continuously impact and rotate in the axial direction. Grind for 2~3 minutes to see the joint surface of the needle valve taper valve line. But special attention should be paid to the fact that the abrasive paste must not be applied or touched on the cylindrical guide surface of the needle valve to prevent abrasion from damaging the smoothness of the cylindrical guide surface of the needle valve. Grind away the traces of damage, use a syringe to inhale clean diesel oil, and flush the abrasive paste against the nozzle body hole. Then use chromium oxide to grind the injector body in the same way as shown in Figure 6, and then grind it with engine oil for 1~2min, so that the valve line of the needle valve taper reaches the surrounding smoothness. The width of the joint surface of the valve wire is generally about 0.1mm.