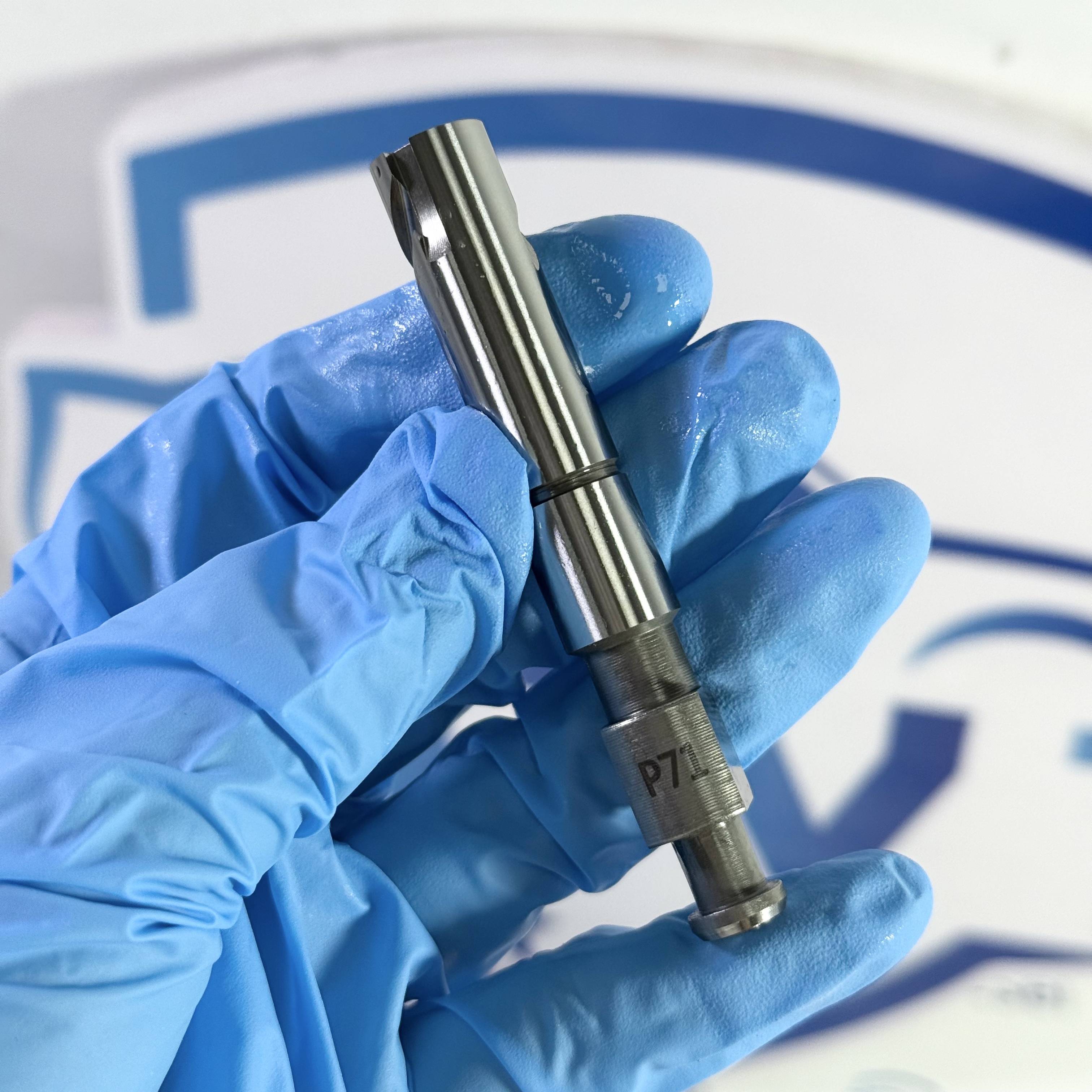

Made in China Fuel Injection Pump Plunger P71 Pump Elements Engine Accessories

products description

| Reference. Codes | P71 |

| OE/OEM Codes | / |

| Application | / |

| MOQ | 5 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Paypal, Western Union or as your requirement |

Study on the Influence of Lightweight Plunger Structural Design on Engine Fuel Economy

Abstract

In modern high-pressure fuel injection systems, the plunger is a key component responsible for precise fuel delivery and pressure buildup. However, its reciprocating motion introduces significant inertial loads, friction losses, and mechanical vibration. Lightweight structural design of the plunger can effectively reduce mechanical energy consumption and improve the overall fuel economy of internal combustion engines. This paper investigates the relationship between plunger mass reduction, structural optimization, and engine fuel efficiency through theoretical analysis, finite element modeling, and experimental validation.

1. Introduction

With increasingly stringent emission and fuel economy regulations, the optimization of key components in the fuel injection system has become a major focus of engine design. The plunger in the high-pressure pump operates at frequencies exceeding 100 Hz, where inertial and frictional losses account for a considerable portion of the mechanical input power. Reducing the plunger mass without compromising strength and fatigue resistance can enhance response speed, reduce driving torque, and improve fuel economy at both low and high loads.

2. Lightweight Design Strategies

The lightweight design of plungers primarily involves structural, material, and manufacturing innovations:

-

Structural Optimization: Finite Element Analysis (FEA) is used to identify stress concentration regions. By adopting hollow-core, tapered, or rib-reinforced geometries, weight can be reduced by 15–25% while maintaining stiffness.

-

Material Substitution: Advanced high-strength steels, titanium alloys, and ceramic composites provide higher strength-to-weight ratios and improved wear resistance under high-pressure conditions.

-

Surface Engineering: Application of DLC (diamond-like carbon) or ceramic coatings can offset the wear risks introduced by reduced cross-sectional thickness, ensuring long-term durability.

3. Impact on Fuel Economy and System Efficiency

Lightweight plungers contribute to fuel economy improvement through several mechanisms:

-

Reduced Inertial Loss: Lower mass decreases reciprocating inertia, reducing the energy required to drive the plunger each cycle.

-

Enhanced Dynamic Response: Improved acceleration characteristics enable more accurate fuel metering, enhancing combustion efficiency and reducing unburned fuel.

-

Decreased Frictional Power Loss: Optimized contact geometry and coatings minimize boundary lubrication friction during cold starts and high-speed operation.

-

Improved Mechanical Efficiency of the Pump: Experimental results indicate that for every 10% reduction in plunger mass, the mechanical efficiency of the high-pressure pump can increase by 1–2%, translating into measurable fuel savings at the engine level.

4. Simulation and Experimental Verification

A coupled dynamic–thermal simulation model was established to evaluate the influence of mass reduction on stress, deformation, and temperature rise. Bench tests were conducted under steady and transient conditions, confirming that lightweight plungers exhibit lower vibration amplitude and improved flow stability. The correlation between plunger optimization and brake specific fuel consumption (BSFC) demonstrated an average reduction of 2–3%.

5. Conclusion

Lightweight plunger structural design offers a promising pathway to improving engine fuel economy by reducing inertial and frictional losses without sacrificing durability. Through advanced materials, structural optimization, and surface engineering, the plunger can achieve both high strength and low mass. Future research should focus on intelligent topology optimization and additive manufacturing techniques to further enhance design flexibility and efficiency in high-pressure fuel systems.