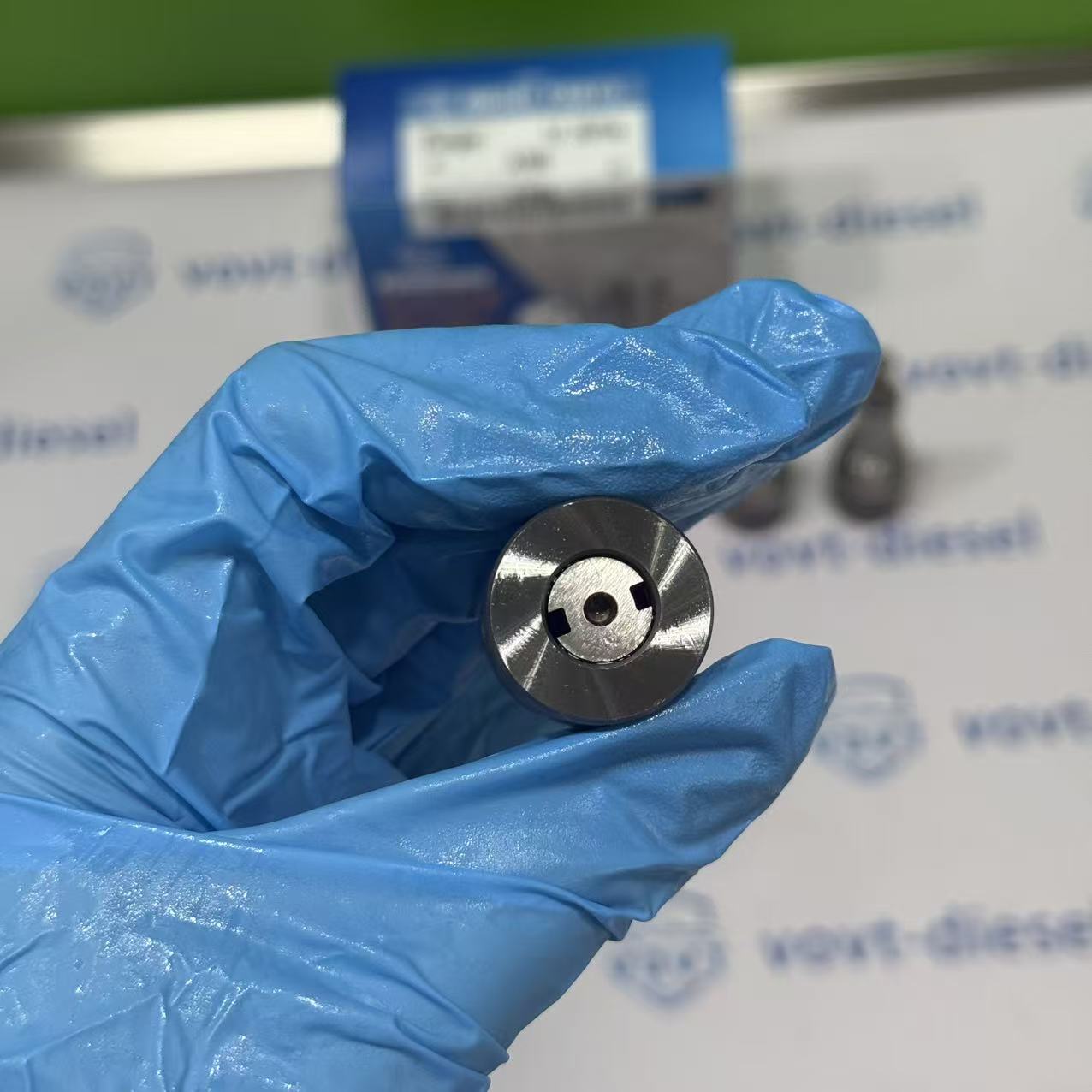

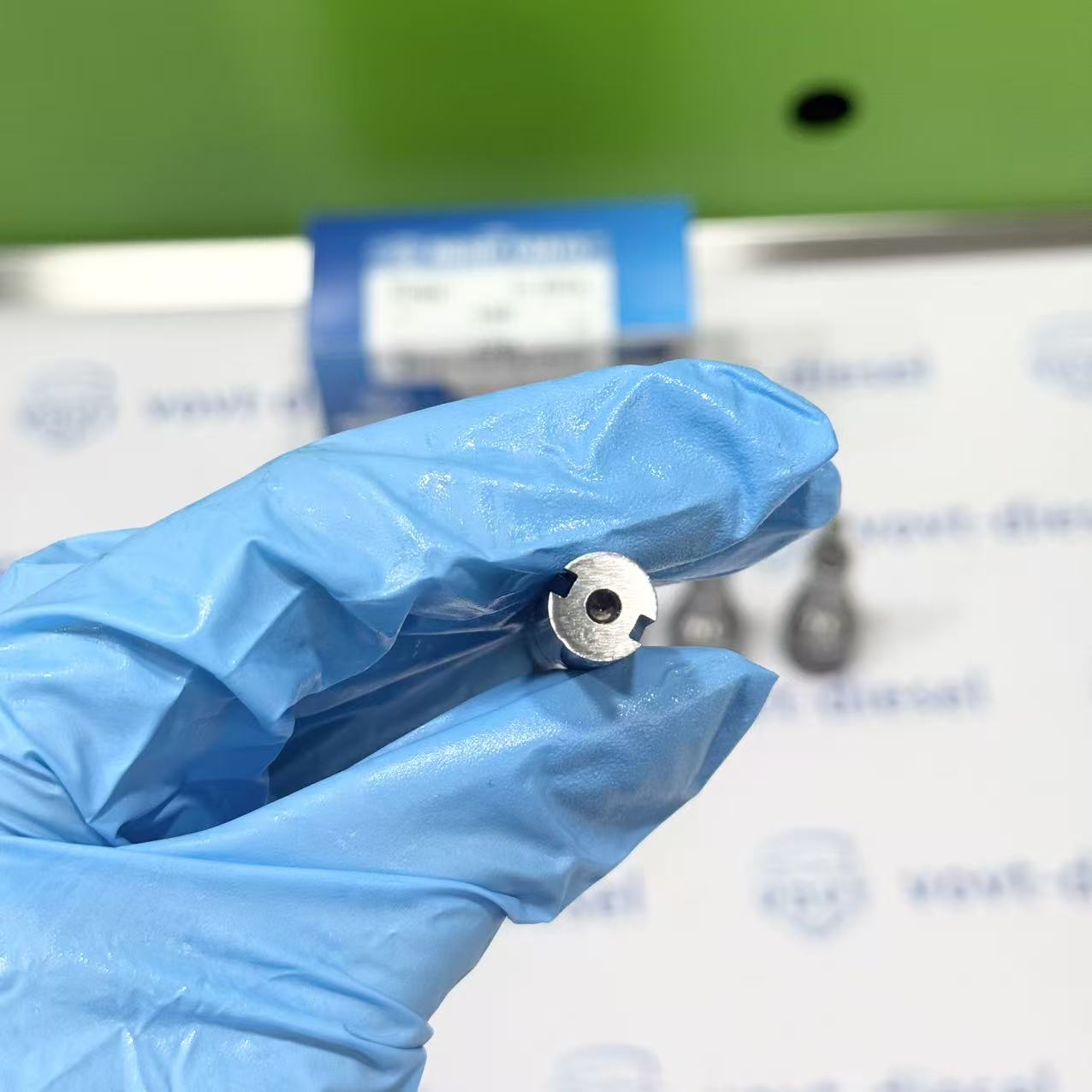

Made in China Fuel Injection Pump Plunger A765 Pump Elements Engine Accessories

products description

| Reference. Codes | A765 |

| OE/OEM Codes | / |

| Application | / |

| MOQ | 5 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Paypal, Western Union or as your requirement |

Multi-Objective Optimization of Helical Groove Structural Parameters on Plunger Head for Fuel Injection Accuracy

Abstract

The plunger head, as a critical element in high-pressure fuel pumps, often incorporates helical grooves to control fuel delivery and injection timing. The geometry of these grooves directly influences injection accuracy, pressure stability, and overall combustion efficiency. This paper investigates the influence of helical groove structural parameters on injection precision and establishes a multi-objective optimization framework to balance efficiency, stability, and durability.

1. Introduction

Accurate fuel injection is essential for meeting stringent emission regulations and achieving high thermal efficiency in modern diesel engines. The helical groove on the plunger head regulates the effective stroke length and fuel cut-off characteristics. However, improper groove geometry may result in pressure fluctuations, delayed injection timing, and poor repeatability. Therefore, a systematic optimization of helical groove parameters is necessary to improve injection performance.

2. Methodology

-

Geometric parameters studied: groove depth, width, lead angle, and helix pitch.

-

Numerical modeling: A three-dimensional CFD model coupled with plunger kinematics was developed to simulate transient flow, pressure evolution, and leakage in different groove designs.

-

Optimization approach: A multi-objective genetic algorithm (MOGA) was applied, considering injection quantity accuracy, response time, and wear resistance as key objectives.

-

Experimental validation: A high-pressure test bench equipped with displacement sensors and pressure transducers was used to evaluate optimized designs.

3. Results

-

Groove depth and width: Deeper grooves enhanced control flexibility but increased leakage, while narrower widths improved sealing at the cost of slower response.

-

Helix angle: A moderate angle provided better fuel delivery linearity, whereas excessively steep angles caused unstable injection timing.

-

Multi-objective outcomes: The optimization achieved a compromise design that reduced injection quantity deviation by 12% and improved pressure stability by 15% compared with conventional designs.

4. Discussion

The helical groove structure plays a dual role: regulating effective fuel delivery and influencing dynamic flow resistance. Multi-objective optimization proves effective in addressing the inherent trade-offs between precision, efficiency, and durability. Additionally, the combination of CFD-based analysis with evolutionary algorithms provides a robust method for capturing nonlinear interactions among parameters.

5. Conclusion

This study demonstrates that helical groove structural parameters on plunger heads significantly affect fuel injection accuracy. Multi-objective optimization offers a practical pathway to achieve balanced performance improvements. The findings provide valuable guidance for the design of advanced plunger systems in high-pressure fuel injection pumps, contributing to cleaner combustion and enhanced engine efficiency.