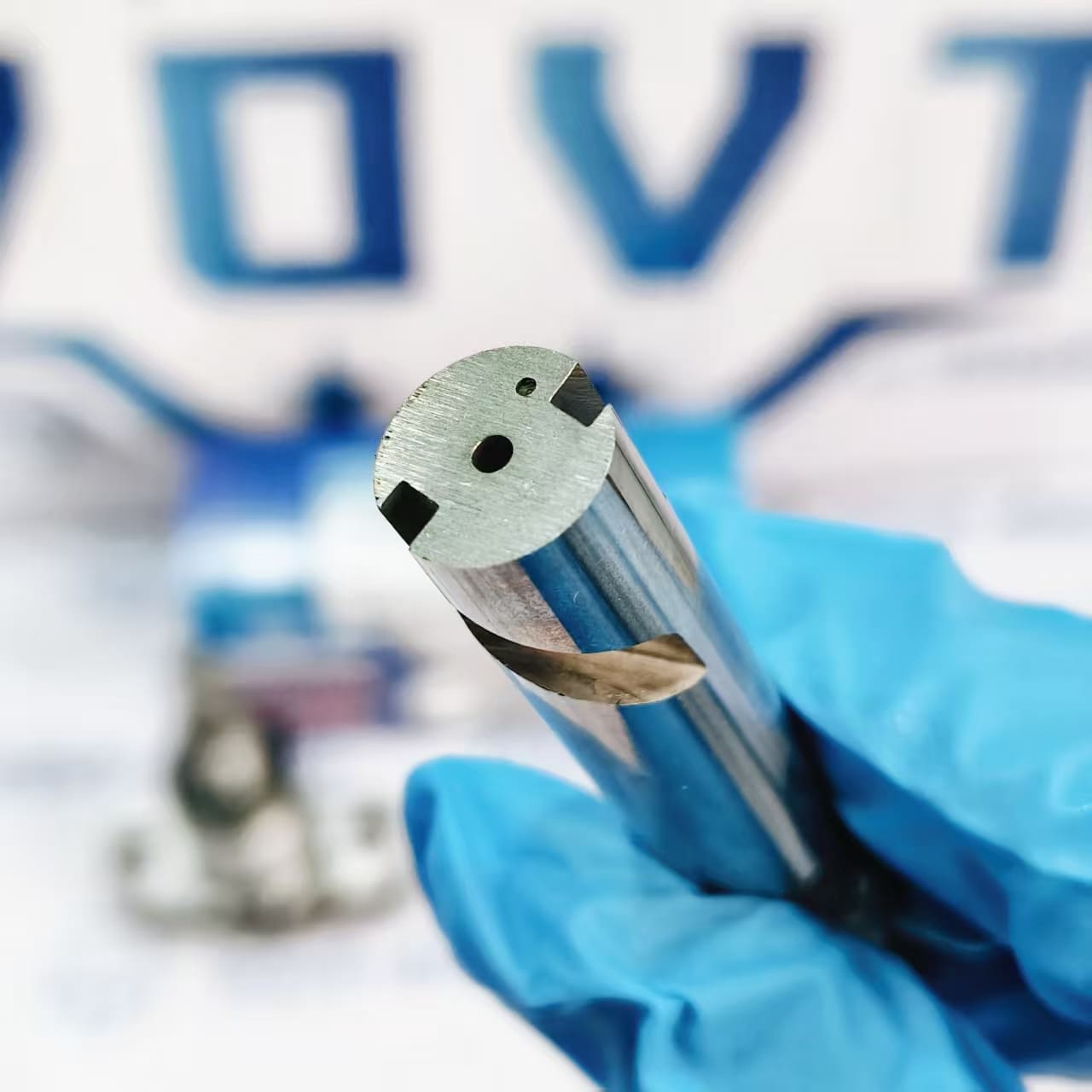

Made in China Fuel Injection Pump Plunger 733 9 412 366 454 Pump Elements Engine Accessories

products description

| Reference. Codes | 733 |

| OE/OEM Codes | / |

| Application | / |

| MOQ | 5 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Paypal, Western Union or as your requirement |

Dynamic Modeling and Vibration Noise Suppression Methods of Reciprocating Plunger Motion

Abstract

Reciprocating plunger mechanisms are widely used in high-pressure fuel pumps, hydraulic systems, and precision dosing devices. However, the alternating motion of the plunger induces severe dynamic impact, vibration, and noise, which deteriorate system stability and reduce service life. This paper presents a dynamic modeling approach for plunger reciprocating motion, analyzes the main sources of vibration and acoustic excitation, and proposes effective methods for vibration and noise suppression through structural optimization, damping control, and intelligent regulation.

1. Introduction

In high-pressure fuel injection systems, the plunger repeatedly performs suction and discharge strokes at high frequency. The rapid pressure variation inside the chamber and the alternating inertial forces generate complex vibration responses. These vibrations propagate through the housing and manifest as audible noise, negatively affecting system reliability and passenger comfort. Therefore, establishing an accurate dynamic model and developing targeted suppression strategies are of great significance for improving mechanical efficiency and noise control.

2. Dynamic Modeling of Plunger Motion

The plunger’s motion can be described by the nonlinear dynamic equation:

mx¨+cx˙+kx=Fp(t)+Fh(t)

where m is the plunger mass, c the damping coefficient, k the stiffness of elastic support, F_p(t) the pressure force, and F_h(t) the hydrodynamic reaction. The system exhibits strong coupling between mechanical and fluid dynamics. During suction, pressure drop causes cavitation-induced oscillations, while in compression, sudden pressure rise results in impact forces on the valve seat and pump head. Finite element analysis (FEA) and computational fluid dynamics (CFD) coupling are typically employed to simulate these transient interactions.

3. Sources of Vibration and Noise

-

Inertial Force Fluctuations: Non-sinusoidal motion profiles generate second- and third-order harmonic vibrations.

-

Hydraulic Pressure Pulsation: Rapid pressure transitions lead to acoustic excitation within the fuel chamber.

-

Structural Resonance: Matching between plunger reciprocation frequency and natural frequency of the housing amplifies vibration amplitude.

-

Valve Impact: Repeated contact between plunger and valve components produces mechanical impulse noise.

4. Vibration and Noise Suppression Methods

-

Profile Optimization: Designing smoother cam or servo drive profiles reduces acceleration peaks and inertial impacts.

-

Hydraulic Damping: Introducing damping chambers or flexible accumulators smooths pressure pulsations.

-

Material and Structural Design: Using high-damping composite materials and isolating support mounts lowers transmission of vibration energy.

-

Active Control Strategies: Implementing real-time control algorithms to modulate plunger motion trajectory based on feedback signals effectively minimizes resonance excitation.

-

Acoustic Optimization: Applying sound-absorbing coatings or structural enclosures reduces radiated noise in the audible frequency range.

5. Conclusion

Dynamic modeling and vibration suppression of reciprocating plungers are critical for achieving high-performance and low-noise operation in modern fuel and hydraulic systems. By integrating mechanical design optimization, coupled fluid–structure simulation, and adaptive control techniques, vibration energy can be effectively reduced and system reliability enhanced. Future work should focus on intelligent self-adaptive damping systems and advanced material applications to further mitigate noise and extend the service life of high-pressure reciprocating mechanisms.