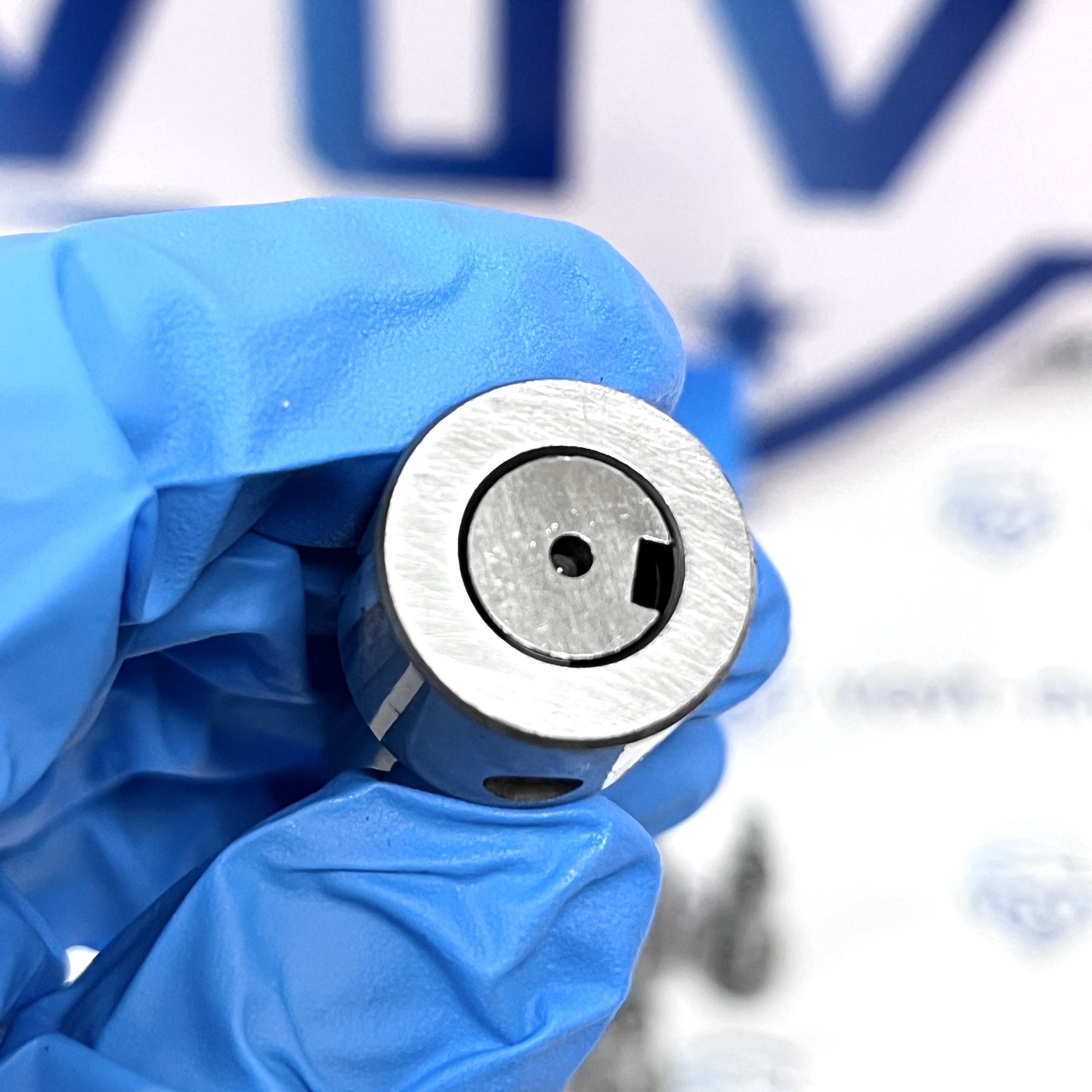

Made in China Fuel Injection Pump Plunger A160 Pump Elements Engine Accessories

products description

| Reference. Codes | A160 |

| OE/OEM Codes | / |

| Application | / |

| MOQ | 5 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Paypal, Western Union or as your requirement |

Study on the Dynamic Sealing Mechanism of the Plunger–Cylinder Clearance in High-Pressure Plunger Pumps

Abstract

In high-pressure plunger pumps, the microscopic clearance between the plunger and the cylinder liner is not only essential for relative sliding motion but also serves as the key factor ensuring effective high-pressure sealing. With working pressures exceeding 200 MPa, the transient flow behavior, thermal effects, and lubrication state of fuel within the clearance significantly affect volumetric efficiency, leakage control, and component durability. Based on fluid dynamics and elastohydrodynamic lubrication theory, this paper investigates the dynamic sealing mechanism of the plunger–cylinder clearance and explores critical parameters for optimized design.

1. Introduction

High-pressure plunger pumps are widely employed in diesel engine fuel injection systems, where their performance directly influences combustion efficiency and emission levels. The plunger–cylinder pair, as the core friction pair, must simultaneously maintain sufficient sealing capacity and adequate lubrication during high-pressure fuel delivery. Achieving a balance between micro-scale sealing and frictional loss within a clearance of only a few microns is a major challenge in plunger pump design.

2. Analysis of the Dynamic Sealing Mechanism

The clearance between the plunger and cylinder liner typically ranges from 1–3 μm. Under high-pressure operation, fuel flow within the clearance demonstrates a coupling of viscous flow and pressure-driven flow. The dynamic sealing mechanism can be summarized as follows:

-

Hydrodynamic effect: The reciprocating motion of the plunger generates oil film pressure, which suppresses high-pressure fuel leakage.

-

Pressure gradient barrier: The axial pressure distribution forms a sealing barrier that resists leakage.

-

Elastic deformation effect: High pressure induces slight elastic deformation in both the plunger and liner, altering clearance distribution and enhancing sealing performance.

-

Thermal coupling effect: Friction and high-pressure flow increase the fuel temperature, modifying viscosity and consequently influencing sealing effectiveness.

3. Numerical Simulation and Experimental Validation

A CFD model of the plunger–cylinder clearance flow was developed, incorporating dynamic meshing to capture the impact of plunger reciprocation on the clearance flow field. Results indicate that clearance geometry directly determines leakage rate and oil film load capacity. As plunger velocity increases, dynamic oil film pressure rises, thereby enhancing sealing capability; however, frictional energy losses also increase correspondingly. Experimental results validated the simulation findings, confirming that optimized clearance can achieve a balance between sealing effectiveness and efficiency within a specific pressure range.

4. Structural Optimization and Design Considerations

To address leakage and wear issues under ultra-high pressure, the following design strategies are proposed:

-

Optimized clearance control: Maintain clearance within 1–2 μm to balance sealing and lubrication.

-

Surface texturing design: Introduce micro-dimples or helical grooves on the plunger surface to stabilize oil film and improve lubrication.

-

Advanced materials and coatings: Apply low-friction coatings such as DLC to enhance wear resistance and prevent scuffing.

-

Thermal management: Incorporate cooling and flow channel optimization to minimize adverse thermal effects on sealing performance.

5. Conclusion

The dynamic sealing mechanism of the plunger–cylinder clearance in high-pressure plunger pumps is governed by the combined influences of fluid dynamics, elastic deformation, and thermal effects. Proper clearance control, surface engineering techniques, and material optimization can significantly improve sealing performance and operational stability. This study provides theoretical insights and engineering guidance for the efficient and durable design of high-pressure plunger pumps.