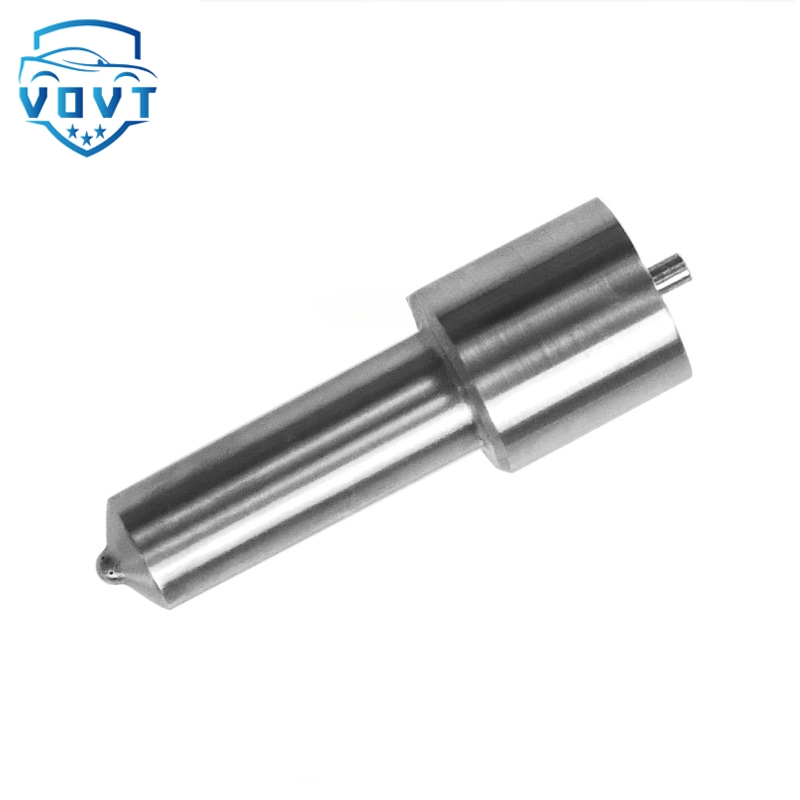

High Quality Common Rail Diesel /Fuel Injector Nozzle DLLA146SM224

| Produce Name | DLLA146SM224 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

How to clean the nozzle

1. Use the "bottle" method for cleaning. This method is simple and easy, only need to insert the appropriate cleaning agent into the special equipment, according to the provisions of the connecting pipe respectively into the inlet and the inlet pipe, let the engine run for 20 minutes. Cleaning process because to wash the carbon in the cylinder, in terms of environmental protection, exhaust emissions will certainly temporarily exceed the standard.

2. Clean with a removable cleaner. The cleaning principle of the no-disassembly cleaning machine is to use the pressure and circulation network of the original engine system, clean the carbon in the cylinder with cleaning agent instead of oil combustion, and then discharge by the discharge system. The advantage of free cleaning is convenient and fast, and the cleaning effect of the nozzle is obvious; Can eliminate engine weakness, poor acceleration, improve car power and driving performance.

The disadvantage of the above method is that the front section of the inlet can not be cleaned.

3. Free cleaning method. It should be noted that there are many kinds of cleaning agents on the market at present, and different specifications. The cleaning agent with poor quality is easy to damage the inlet and exhaust valve, piston and cylinder wall in the cleaning process because of the different calorific value. The nozzle and sealing ring of fuel injector, three - way catalyst are damaged to some extent.

4. Car friends with strong hands-on ability can buy a can of good quality carburetor cleaning agent, two wires, and find a helper. Connect the positive and negative electrodes of the battery with the wire respectively, and the other end is connected to the two poles of the nozzle plug respectively. Wrap some insulation tape to separate it, and pay attention to the possibility of short circuit. Then the carburetor cleaning agent nozzle is wrapped with raw tape, and the top is on the oil inlet of the nozzle, and the top is tight as far as possible. Spray cleaning agent while pulsed power on and off.

At present, the common use is ultrasonic cleaning machine for cleaning, need to remove the nozzle. Its advantage is that it can be used to detect whether the nozzle atomization, response degree, switching sensitivity, whether the oil leakage, etc. For blind holes, uneven places can be evenly cleaned to reduce the cost of cleaning and labor damage.