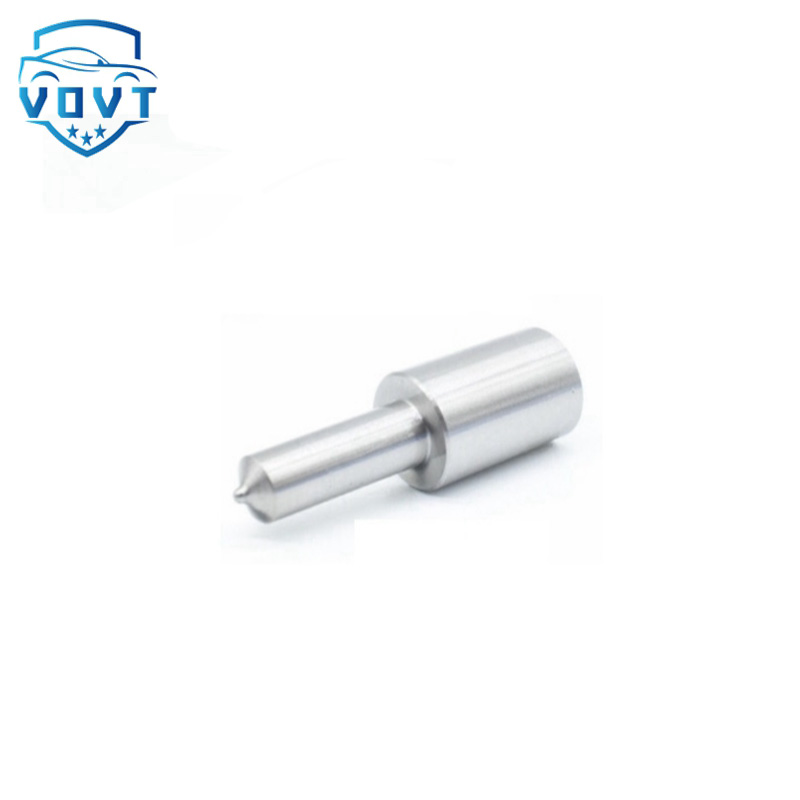

High Quality Common Rail Diesel /Fuel Injector Nozzle DLLA145P014

| Produce Name | DLLA145P014 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Disassembly and Inspection of Injector Head and Grinding Repair Skills of Needle Valve Coupling (part 1)

The fuel injector is one of the important parts of the diesel engine, and its working performance directly affects the power, economy, reliability and emission of the diesel engine.

When the diesel engine is running at high speed, the fuel injected into the cylinder from the fuel injector must be ignited as soon as possible, and burn quickly at the best time, so as to convert the chemical energy of the fuel into the mechanical energy that drives the engine to the maximum extent. To achieve this, the injector should meet the following requirements:

(1) The fuel injector should have a certain injection pressure and range.

The injection pressure of the injector is set by the pressure regulating spring, and the range is not only related to the injection pressure and the back pressure of the combustion chamber, but also related to structural factors such as the diameter of the nozzle hole and the shape of the needle valve.

(2) There must be a suitable injection direction and injection cone angle that match the shape of the combustion chamber.

(3) There must be good atomization performance, which is to ensure that the injected fuel can be quickly and evenly mixed with air to obtain sufficient combustion.

(4) The timing of stopping the fuel injection is neat, that is to say, the fuel supply can be cut off quickly and completely at the end of the fuel injection, and no fuel leakage is allowed.

(5) It should be able to withstand severe conditions such as high temperature and high pressure, so that it can be used safely for a long time. Because the fuel injector is exposed to high temperature and high pressure gas, the temperature and pressure change suddenly, and the high speed fuel flow scours, the fuel impurities wear and the corrosive gas (sulfur dioxide) produced in the fuel corrodes and wears.

Therefore, in order to keep the fuel injector in good working condition, it is necessary to strengthen the regular inspection and maintenance of the engine combustion chamber components and the fuel system.