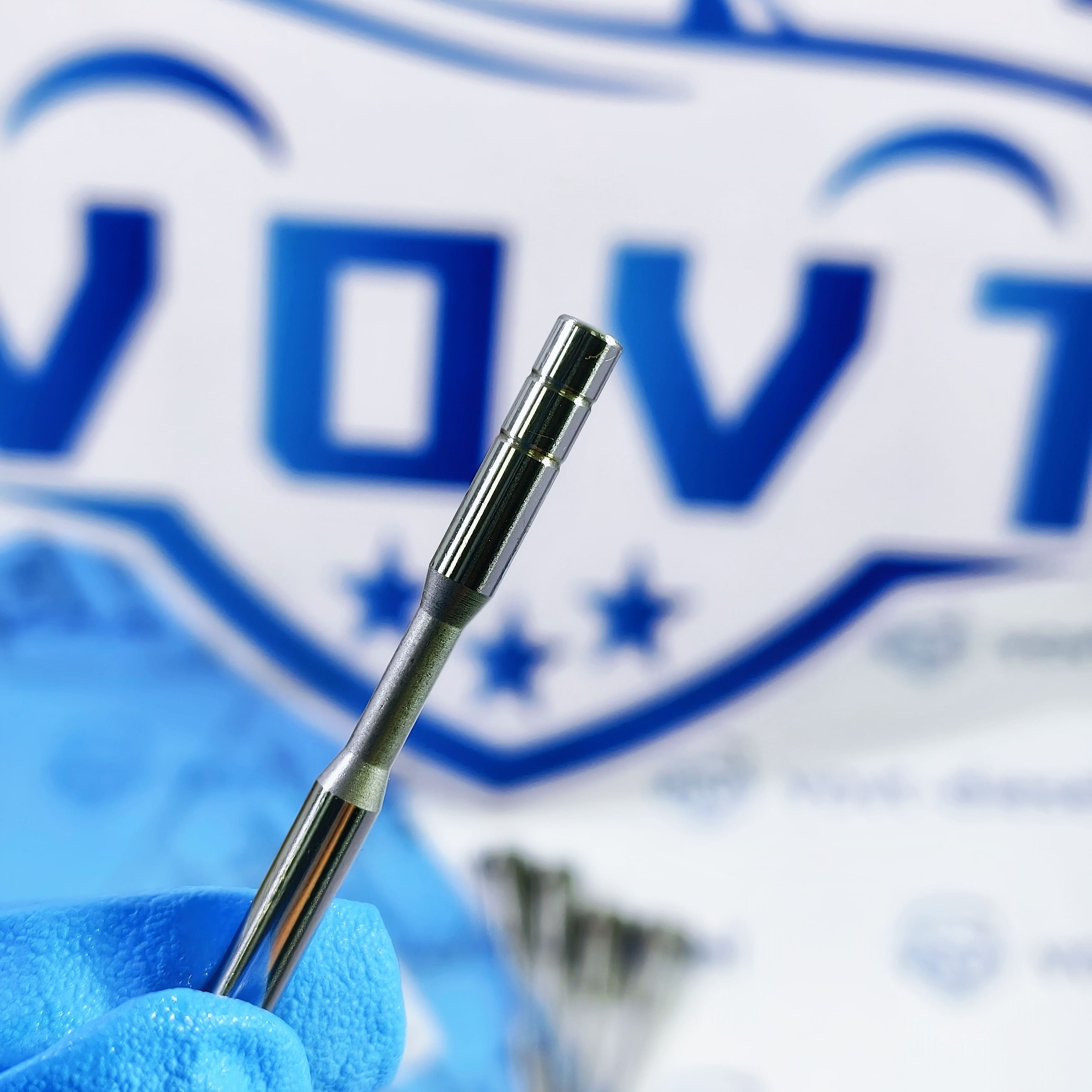

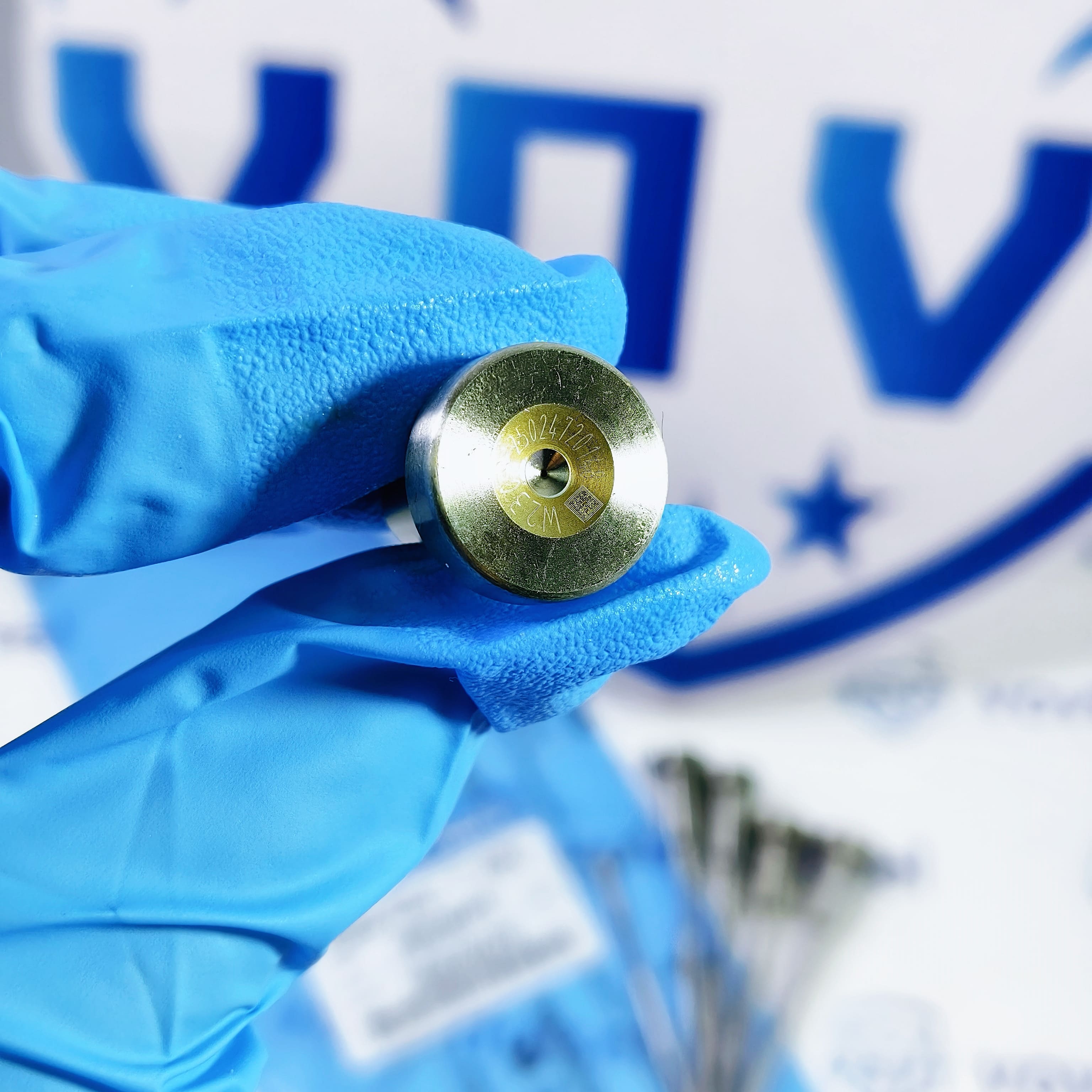

High Precision New Diesel Injector Control Valve F00RJ02472 Valve Assembly for Fuel Injector Engine Spare Parts

Products Description

| Reference Codes | F00RJ02472 |

| Application | / |

| MOQ | 6 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Failure Mechanism and Life Prediction of Sealing Materials in Valve Assemblies under High-Pressure Environments

Abstract

Valve assemblies are widely used in hydraulic control and fuel injection systems, where sealing reliability is crucial for maintaining high efficiency and pressure stability. In high-pressure environments, sealing materials are exposed to severe mechanical, thermal, and chemical stresses, leading to degradation and eventual failure. This study investigates the failure mechanisms of sealing materials in valve assemblies and explores life prediction approaches based on material properties, stress conditions, and experimental validation.

1. Introduction

With the continuous increase in system operating pressure in modern hydraulic and fuel injection technology, the demand for sealing reliability in valve assemblies has grown significantly. Failures of sealing materials not only lead to leakage and efficiency loss but may also induce catastrophic system damage. Therefore, understanding failure mechanisms and establishing accurate life prediction models are essential for ensuring long-term reliability.

2. Failure Mechanisms of Sealing Materials

The failure of sealing materials in high-pressure valve assemblies is influenced by multiple factors:

-

Mechanical fatigue: Repeated high-pressure cycles induce crack initiation and propagation, reducing sealing integrity.

-

Thermal degradation: High operating temperatures accelerate aging of elastomeric seals, resulting in hardening, shrinkage, and loss of elasticity.

-

Chemical attack: Long-term exposure to hydraulic oils or fuels causes swelling, corrosion, or chemical softening of the sealing material.

-

Creep and stress relaxation: Under constant high pressure, polymer-based seals may undergo viscoelastic deformation, leading to permanent loss of sealing capability.

-

Abrasive wear: Micro-gap flow carries particles that erode sealing surfaces, accelerating failure.

3. Life Prediction Approaches

Life prediction of sealing materials under high-pressure conditions can be achieved through combined experimental and theoretical methods:

-

Empirical models: Based on accelerated aging tests under controlled pressure, temperature, and chemical environments, empirical life equations can be established.

-

Fracture mechanics: By analyzing crack growth rates under cyclic loading, fatigue life of sealing materials can be predicted.

-

Viscoelastic models: Time-dependent creep and stress relaxation behavior can be described using rheological models such as the Maxwell or Burgers model.

-

Numerical simulation: Finite element analysis (FEA) and multiphysics coupling methods enable detailed stress distribution analysis, providing insights into critical failure locations.

-

Data-driven prediction: Machine learning models trained with historical failure data can enhance prediction accuracy under complex working conditions.

4. Engineering Strategies for Reliability Enhancement

To extend sealing material life in high-pressure valve assemblies, several engineering measures can be implemented:

-

Selection of advanced composite or nano-reinforced elastomers with higher strength and chemical resistance.

-

Surface treatment and coating technologies to reduce abrasive wear and chemical interaction.

-

Optimization of valve geometry to achieve uniform stress distribution and minimize local concentration.

-

Adaptive maintenance schedules based on real-time monitoring of leakage and seal deformation.

5. Conclusion

Sealing materials in valve assemblies face complex degradation mechanisms under high-pressure environments, including mechanical fatigue, thermal aging, chemical corrosion, and creep deformation. Life prediction requires an integrated approach combining experimental testing, theoretical modeling, and advanced simulations. By developing more robust materials and employing predictive maintenance strategies, the reliability and service life of valve assemblies can be significantly improved.