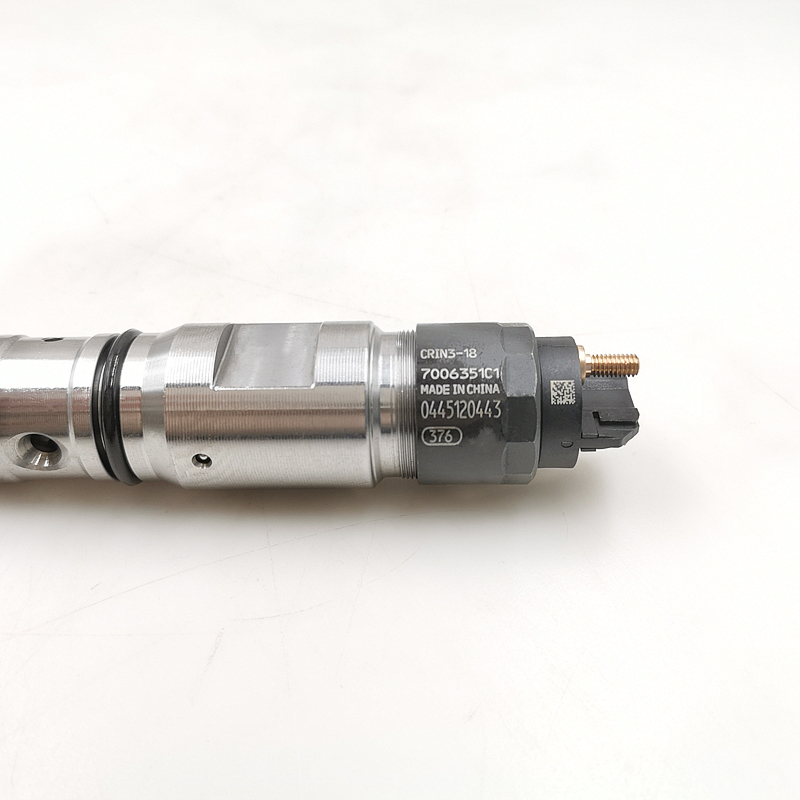

Diesel Injector Fuel Injector 0445120443 compatible with injector BMW 525 E60 / E61 2.5 L M57 I6

| Produce Name | 0445120443 |

| Engine Model | BMW 2.5L M57 I6 |

| Application | BMW 525 E60 / E61 |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Reasons for the decrease in service life of common rail injectors

1) During the manual repair of the high-pressure common rail injector, the maintenance specification is not clear, and the debugging is not carried out according to the maintenance specification. With formal training, it is not clear how to adjust and what the function of each adjustment point is. Blind adjustment will lead to a decrease in the service life of the injector. Through investigation, it was found that many maintenance personnel found that the full-load fuel injection volume was not within the set value during maintenance, and blindly adjusted the armature lift. If the armature lift adjustment exceeds the set value, the impact force of the valve ball on the valve seat becomes larger, and the valve The risk of cavitation on the seat surface increases, resulting in excessive oil return and functional failure of the injector after a period of use.

2) The traditional manual repair process is not standardized, the repairers are very random and there is no standard process, and some vulnerable parts are subjectively felt that they can continue to be used and will not be replaced (such as steel balls, sealing rings, filter elements, etc., as shown in Figure 4) , At the same time, the cleanliness during the repair process is also very poor. It is only necessary to repair it as soon as possible and restore it to use. This will cause the injector to be easily damaged again. Repairers sometimes use sub-factory parts in order to maximize profits. The processing accuracy and material problems of sub-factory parts will seriously affect the performance of the injector