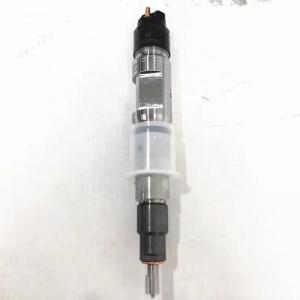

Diesel Injector Fuel Injector 0445120383 compatible with Bosch injector Cummins ISDe ISBe

| Produce Name | 0445120383 |

| Engine Model | Cummins ISDe ISBe |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

The prevention and control measures are in the needle valve parts of the sealing surface coated with an appropriate amount of alumina grinding paste for grinding (grinding process pay attention to do not sprinkle the grinding paste needle valve or needle valve body guide part), then clean with diesel. (2) The needle valve and the needle valve body bite. This is because there are particle impurities in the fuel, so that the couple wear in the process of relative motion, so that the injection pressure drops, poor atomization, insufficient combustion, carbon accumulation near the nozzle gradually plug the needle valve hole, and finally lead to the couple bite, resulting in loss. Working performance, so that the diesel engine power down or starting difficult or even can not start. The prevention and control method is to take out the bitten needle valve couple, soak in hot diesel oil for 1-2 hours, and then use the pliers pad to clamp the needle valve with copper leather shake around, so that the needle valve is slowly extracted from the valve body, then respectively clean with diesel oil. Installed after checking qualified. (3) Corrosion rust on the guide surface of the needle valve and the needle valve body. It is mainly due to the corrosive effect of acid and moisture contained in the fuel. equalizing

Dry fit clearance becomes larger, so that the diesel engine power decreases, the prevention method is to choose high quality oil, fuel oil, on the rust needle

Valve for grinding. (4) The nozzle hole is deformed by the impact of oil pressure, and the aperture becomes larger. Resulting in poor spray oil atomization, pressure drop, range is not enough, the injection Angle becomes smaller. Fuel combustion worsens and economy decreases. (5) Serious ablative surface of needle valve couple parts. The main reason is that the cooling system effect is not good, the temperature in the combustion chamber is too high, so that the surface of the needle valve couple parts is ablated. The latter two damaged needle valve pairs are not easy to continue to use for a long time, need to replace a new needle valve pairs, otherwise it will affect the economy and power of the engine.