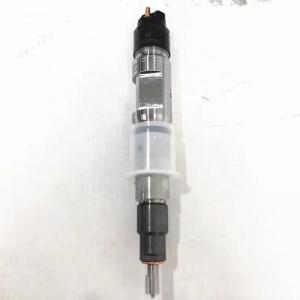

Diesel Injector Fuel Injector 0445120369 Bosch for TATA motors CUMMINS ENGINES

| Produce Name | 0445120369 |

| Engine Model | CUMMINS ENGINES |

| Application | TATA motors |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Correctly disassemble and assemble the fuel injector

The disassembly of the fuel injector should be done in a top-down order, and requires the use of a bench vise and a wrench. The specific steps are: first clamp the nozzle of the fuel injector downwards on the bench vise, and clamp it on a soft metal protection Put it on to prevent extrusion deformation; remove the pressure regulating screw cap, pressure regulating screw and pressure regulating spring in sequence: then fix the injector on the bench vise in reverse, loosen the fastening nut, and take it out Needle valve couple 3]

The dismantled small parts and precision couplings should not be piled up randomly, but should be placed in groups and cleaned and stored in clean diesel oil, and the needle valve couplings should be cleaned by twitching. Then check the parts in turn to determine the maintenance plan. Installation is the reverse process of disassembly. It is worth noting that the oil passage holes should be aligned, and the pressure adjusting screw does not need to be tightened too tightly, so as to facilitate the inspection operation in the later stage.

Correctly select diesel oil according to the operation manual of the diesel engine to ensure the cleanliness of the diesel oil, and absolutely no mechanical impurities are allowed. Mechanical impurities are extremely harmful to the wear of precision coupling parts such as the needle valve and valve seat of the fuel injector and the plunger and plunger sleeve of the fuel injection pump. In severe cases, this type of matching coupling parts will be stuck. Therefore, it is required to use diesel oil that meets the quality requirements and strengthen the management and maintenance of diesel oil filters. The diesel engine is not allowed to run for a long time with overload or no load for a long time, otherwise it will lead to poor fuel injection quality and rapid carbon deposits, resulting in the seizure of the fuel injector.