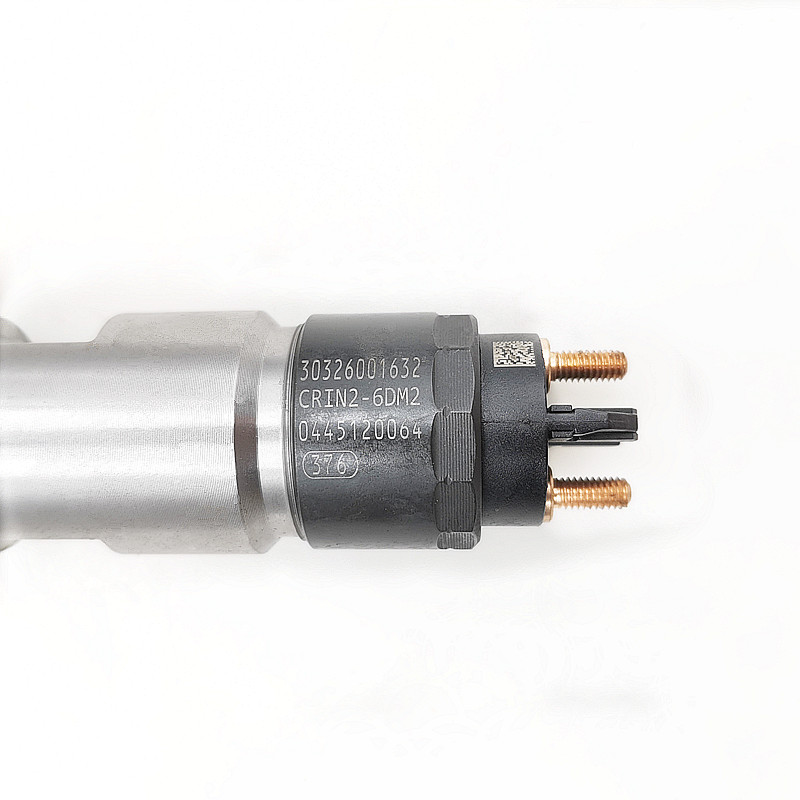

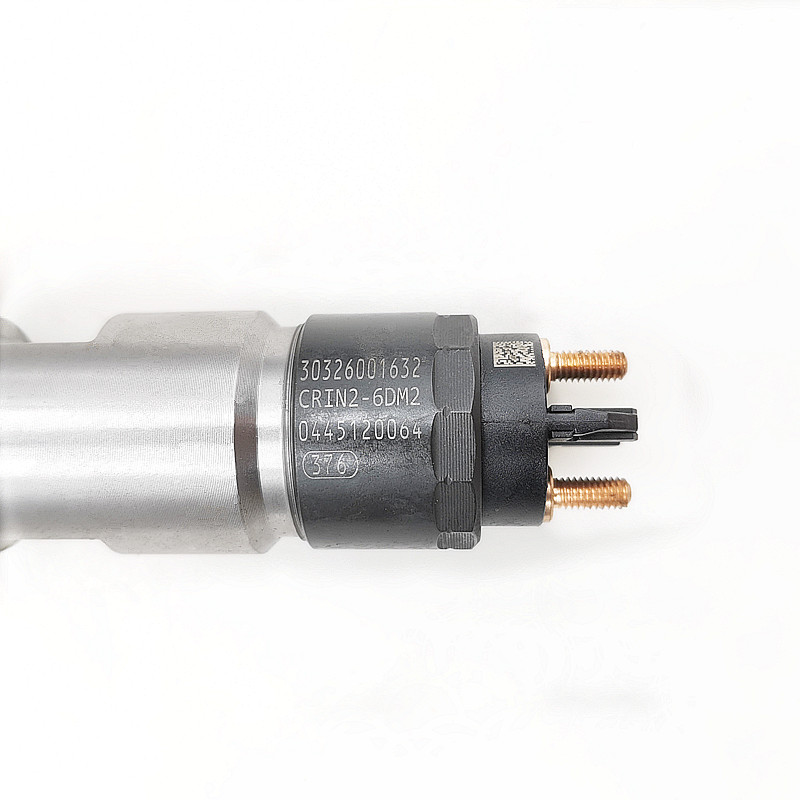

Diesel Injector Fuel Injector 0445120064 0445120136 0445120137 Bosch for Renault Engine 240 Premium II

| Produce Name | 0445120064 0445120136 0445120137 |

| Engine Model | Renault Engine 240 Premium II |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Small hardness of shot peening particles makes the spring surface treatment not pass; · Fatigue fracture accounts for about 1.7% of the total failures, and the rest are fatigue relaxation. · Fatigue relaxation has always been a problem perplexing the spring industry. Since metals are not completely elastomer, micro-deformation (creep) will occur even under the action of stress below the elastic limit, and the influence of permanent deformation on the opening pressure drop of the injector is generally 0.5 Beyond MPa, the pressure drop is mainly caused by the wear of the steel ball or sphere in the tail of the needle valve and the ejector rod, and its influence on the pressure drop is between 0.5 and 2.5 MPa.

(2) Wear of flat gaskets: (1) Flat gaskets have burrs, up to 0.4mm; ② Flat gasket material is soft, ordinary low carbon steel, and hardness HRC47 ~ 54 spring end contact easy to wear and deformation

(3) jacking rod. Pressure regulating screw (or screw sleeve) and pressure regulating screw two end face contact plane wear :40% of the fuel injector appears obvious wear here. There are two reasons :① the contact surface processing is too rough,Ra 12.50 Hn, resulting in a pressure drop of more than 1 MPa; (2) The contact plane is uneven, resulting in uneven spring end face causing bright belt wear, wear maximum depth up to 0.15mm.

(4) Influence of cleanliness of fuel injector: Because the deburring effect of fuel injector deburring equipment of many domestic manufacturers cannot keep up with the requirements of national standards, there is a certain amount of hair and processing abrasive in the fuel injector body, which causes abnormal wear of fuel injector coupling parts, leading to the increase of fit clearance, seal deterioration and pressure drop