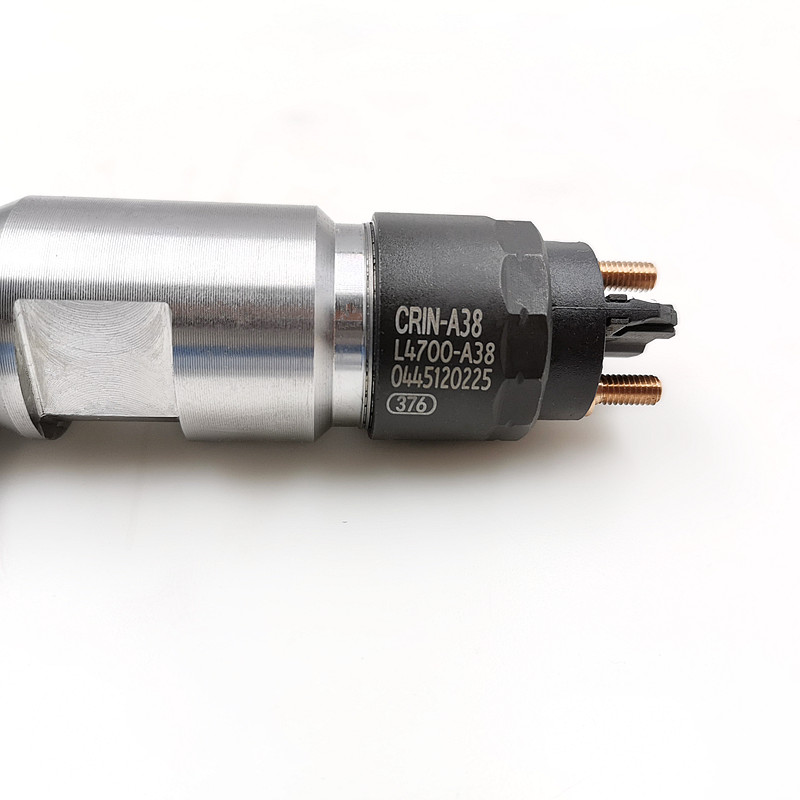

Diesel Injector Fuel Injector 0445120225 0445120439 Boshc Yuchai Yc4g Engine

products detail

Used in Vehicles / Engines

| Product Code | 0445120225 |

| Engine Model | / |

| Application | Gaz Deutz Yamz Engine |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

| Delivery Method | DHL, TNT, UPS, FedEx, EMS or Requested |

The main cause of the stuck needle valve in the fuel injector

- (1) The fuel contains water or acidic substances, causing the needle valve of the injector to corrode and get stuck.

(2) Diesel oil containing solid particulate impurities is used. The impurities accumulate on the inner wall of the needle valve along with the reciprocating movement of the needle valve, causing the needle valve to be stuck.

(3) The oil leakage on the cone surface of the needle valve of the fuel injector is not tightly sealed, causing the surface to burn, and the carbon deposit near the injection hole is serious, causing the needle valve to be stuck.

(4) The copper gasket between the fuel injector and the cylinder head mounting hole is not tightly sealed or the fuel injector is installed skewed. Gas leakage and oil leakage during work will cause the local temperature of the fuel injection nozzle to be too high, causing the needle valve to burn out, deform and get stuck.

In view of the above situation, clean diesel oil with the specified label should be used, and rain, snow or a large amount of dust in the air should be prevented from mixing during the refueling process. At the same time, pay attention to cleaning and replacing the fuel filter on time. During the installation process of the fuel injector, the fixed fuel injector nut should be tightened to ensure that the copper gasket is flat, and materials such as asbestos boards should not be used instead to avoid poor heat dissipation or no sealing effect.

When the needle valve is stuck, immerse the injector assembly in 80C hot diesel oil and let it stand for about 15 minutes. After taking it out, hold the tail of the needle valve with a hand wrapped in a soft cloth and slowly pull it out. Clean and grind it. If the fuel injector test fails, the fuel injector assembly should be replaced. When replacing a new coupler, first immerse the new coupler in 80C diesel oil for about 10 seconds to completely dissolve the anti-rust oil on the surface, and then clean it with clean diesel oil to avoid sticking of the needle valve due to the melting of the anti-rust oil during work. live.

Write your message here and send it to us