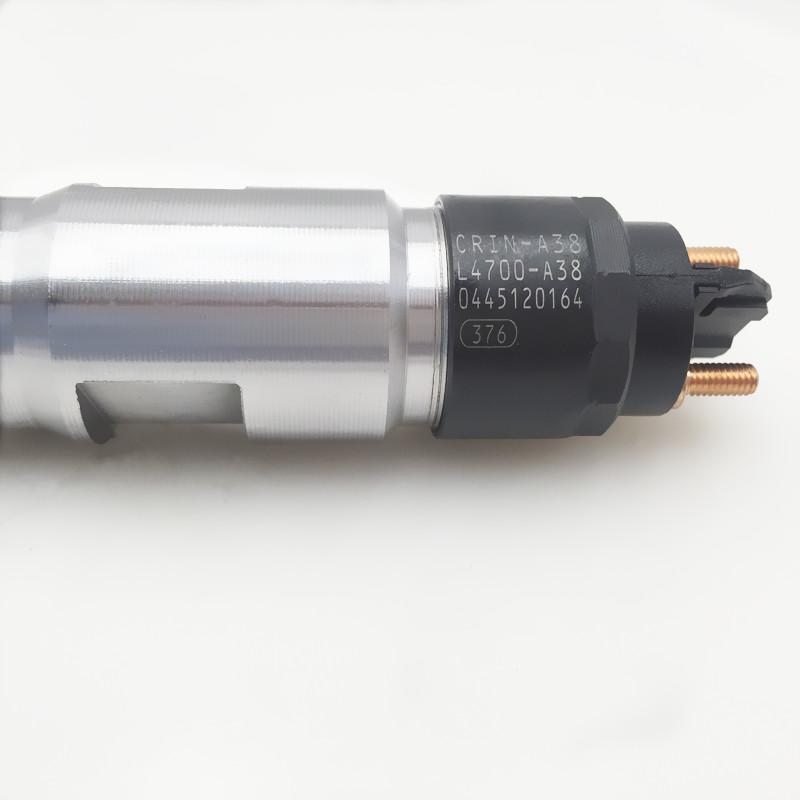

Diesel Injector Fuel Injector 0445120164 Bosch for Yuchai 6g Engine

products detail

Used in Vehicles / Engines

| Product Code | 0445120164 |

| Engine Model | / |

| Application | Gaz Deutz Yamz Engine |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

| Delivery Method | DHL, TNT, UPS, FedEx, EMS or Requested |

Our advantage

- Developing the Model of Fuel Injection Process Efficiency Analysis for Injector for Diesel Engines (part 6)

3.Conclusions

1. It has been demonstrated that when modeling diesel injectors in the ICE in LMS Imagine.Lab AMESim it is possible to preliminarilarily assess the quality of fuel atomization following the results of the analysis of processes in these systems without three-dimensional modeling of fuel spray formation processes.

2. The following design characteristics are proposed as the tools for analyzing the effect of

processes in fuel systems caused on the fuel atomizing quality of the injector:

- distribution of the shares of cycle delivery over the pressure spectrum upstream the injector

nozzles;- change of the mean pressure values upstream the injector nozzles.

3. The blocks for calculating the mean diameter of drops and the range of the spray were modeled as the tools for preliminary assessment of fuel atomization quality.

4. The represented tools allow avoiding the use of labor-intensive three-dimensional calculation and analysing the fuel atomization quality based on modelling the dynamics of atomizers.Based on the simulation results, it can be concluded that it is necessary to increase the injection pressure to reduce the drop mean diameter and increase the spray range. In this connection, the research shall be continued with respect to the rest of the factors and optimization of their values to obtain the maximum high fuel injection quality.Acknowledgements

This work was supported by the Ministry of Education and Science of the Russian Federation in the framework of the implementation of the Program «Research and development on priority directions of scientific-technological complex of Russia for 2014– 2020».References

[1] Reif K. (Hrsg.) 1998, 2002, 2004, 2012 Dieselmotor-Management: Systeme, Komponenten, Steuerung und Regelung 5 Auflage. Vieweg+Teubner (Verlag Springer Fachmedien Wiesbaden) p.544

[2] Grekhov L V, Ivashchenko N A and Markov V A 2013 Fuel equipment and diesel engine

control system: Textbook for Universities (Publishing House of the Legion-Avtodata) p.344

[3] Harun M I, Hoon K Ng and Suyin G 2012 Evaluation of non-premixed combustion and fuel

spray models for in-cylinder diesel engine simulation Applied Energy vol 90 pp 271-279

[4] LMS Imagine.Lab / Web-page: http://www.plm.automation.siemens.com/ru_ru/ products / lms / imagine-lab / amesim /

[5] LMS Imagine.Lab Amesim 2015. LMS Amesim 14 Tutorial guide. p.181