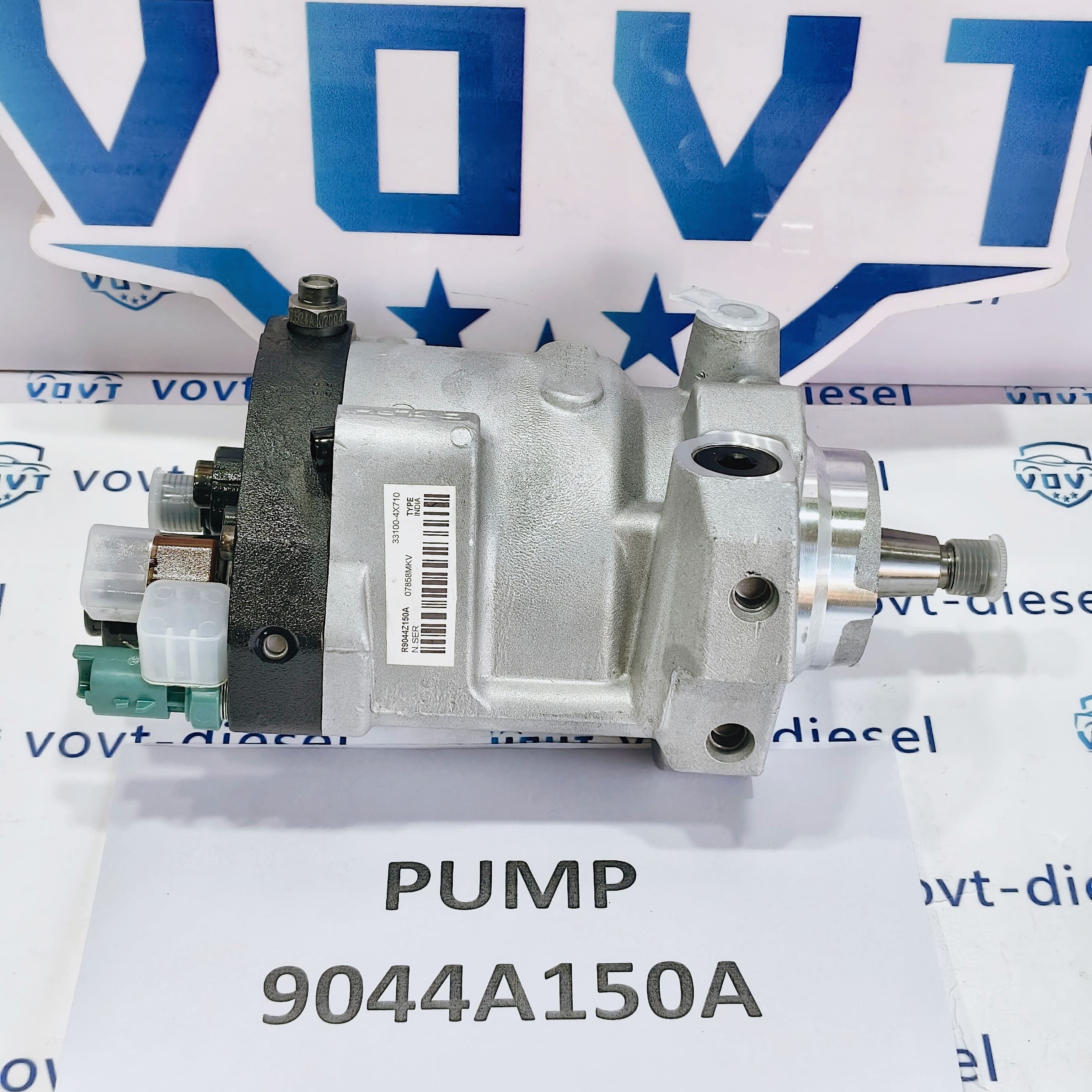

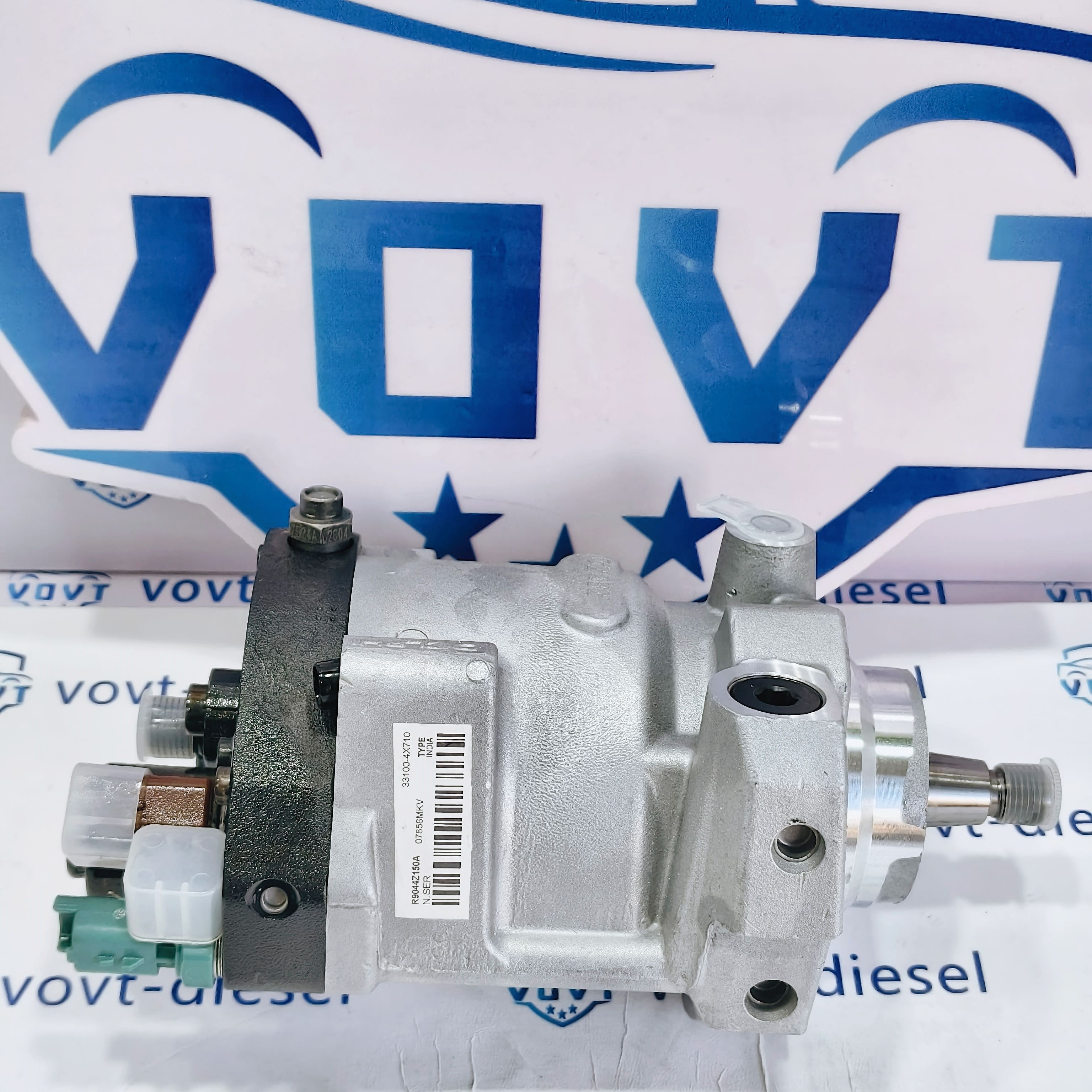

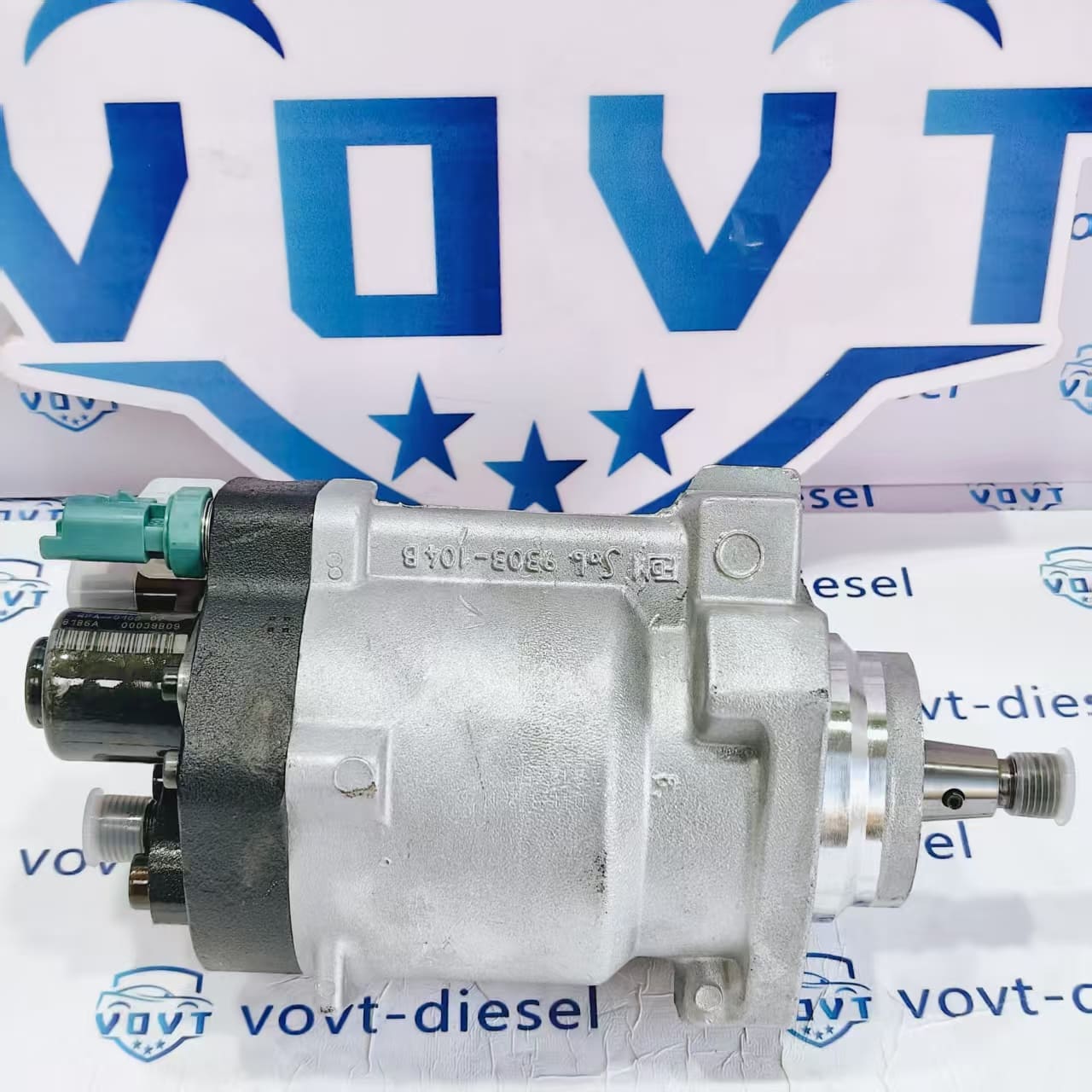

Diesel Fuel Injection Pump 9044A150A Engine Auto Engine Part

products description

| Reference Code | 9044A150A |

| MOQ | 1 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Western Union, Money Gram, Paypal, Alipay, Wechat |

Performance Optimization of Engine Oil Pump under Cold Start Conditions

Abstract

Cold start is one of the most severe operating conditions for internal combustion engines, as oil viscosity remains high at low temperatures, resulting in delayed lubrication, increased friction, and accelerated wear. The engine oil pump, as the key component responsible for oil circulation, plays a decisive role in ensuring lubrication efficiency and mechanical reliability during cold starts. This paper analyzes the challenges faced by oil pumps under cold start conditions, explores optimization methods in structural design, material selection, and control strategies, and proposes feasible pathways for improving performance and durability.

1. Introduction

During cold start, engine oil exhibits poor fluidity due to elevated viscosity, which increases hydraulic resistance in oil passages and delays pressure buildup. Insufficient lubrication in the early seconds of operation significantly accelerates wear of bearings, pistons, and valve trains. Therefore, optimizing oil pump performance under cold start conditions is essential for improving fuel economy, durability, and user experience.

2. Challenges of Cold Start for Oil Pumps

-

High Viscous Resistance: Thickened oil leads to reduced volumetric efficiency and delayed flow response.

-

Slow Pressure Build-Up: Increased resistance prolongs the time required for the pump to establish nominal pressure levels.

-

Leakage and Bypass Activation: Pressure fluctuations may trigger bypass valve opening, reducing effective delivery to critical components.

-

Energy Loss: Elevated torque demand during start-up increases energy consumption and imposes additional load on the starter system.

3. Optimization Strategies

-

Structural Improvements:

-

Adopting variable displacement oil pumps to adjust flow according to real-time demand.

-

Refining internal clearances and port geometry to reduce leakage and enhance low-speed priming capability.

-

-

Material and Coating Selection:

-

Utilizing low-friction coatings such as DLC on pump gears and sliding interfaces to minimize resistance.

-

Employing lightweight, thermally stable alloys to reduce inertia and enhance cold adaptability.

-

-

Control Strategies:

-

Integrating electronic control for active regulation of pump displacement during cold start.

-

Coordinating with engine management systems to increase pump speed in the initial seconds.

-

-

Lubricant Compatibility:

-

Designing pumps to match low-viscosity or multi-grade oils, which maintain better flow at subzero temperatures.

-

4. Simulation and Experimental Validation

Computational Fluid Dynamics (CFD) combined with thermal–viscous modeling enables accurate prediction of cold-start flow behavior. Experimental testing with cold chambers and high-speed pressure sensors is essential to validate priming time, pressure rise rate, and leakage performance. Comparative studies between conventional and optimized pumps can quantify improvements in start-up lubrication.

5. Conclusion

The performance of engine oil pumps under cold start conditions is primarily constrained by oil viscosity, hydraulic resistance, and structural leakage. Through integrated optimization in structural design, materials, coatings, and control strategies, oil delivery efficiency and pressure response can be significantly improved. Future research should focus on intelligent, electronically controlled oil pumps that adapt to transient cold-start conditions, thereby reducing engine wear, enhancing durability, and contributing to higher energy efficiency in modern vehicles.