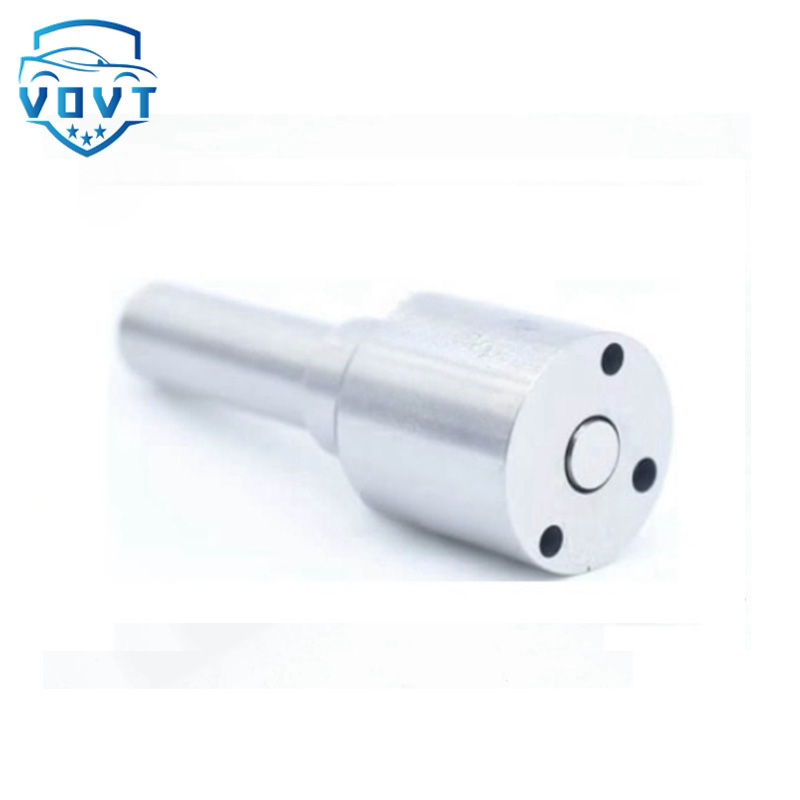

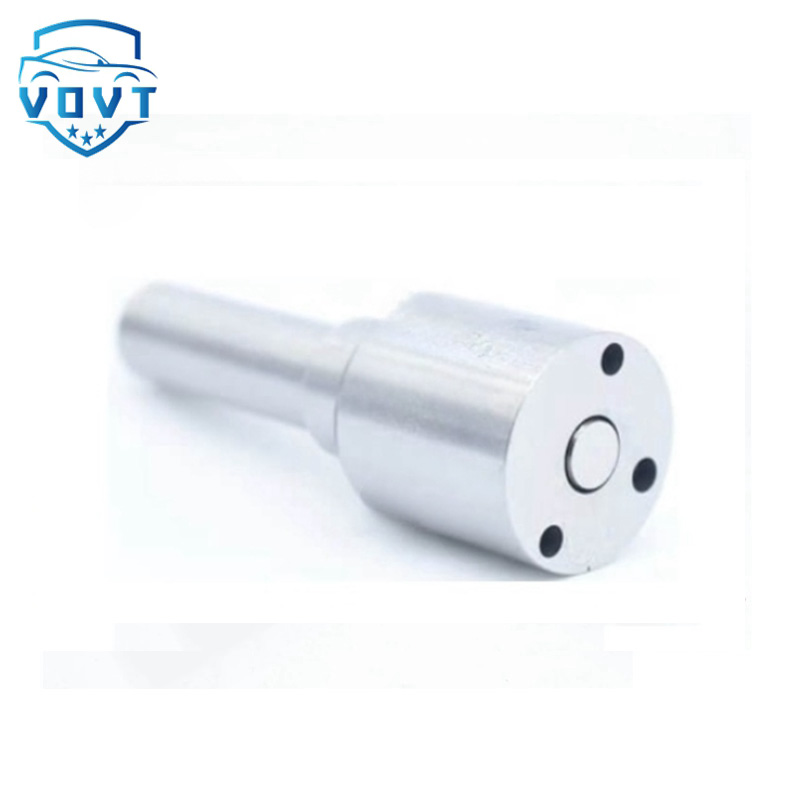

High Quality Common Rail Diesel /Fuel Injector NozzleDLLA148P168

| Produce Name | DLLA148P168 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

High Speed Flow Simulation in Fuel Injector Nozzles (part 6 )

The small size, high speed and a limited time scale makes it very difficult to study the behavior experimentally. Modeling cavitation can be helpful in simulating flow in real size injector nozzles and studying the internal nozzle characteristics, which affect the flow inside a nozzle.

The construction of any simulation of cavitating injector nozzles begins with the fundamental assumptions of which phenomenon to include and which will be neglected [12]. To date, there has been no consensus about whether it is acceptable to assume that small, high-speed cavitating nozzles are in thermal or inertial equilibrium. If one assumes that the nozzle is in thermal equilibrium, then there is presumably no significant delay in bubble growth or collapse due to heat transfer. Heat transfer is infinitely fast and inertial effects limit phase change. The assumption of inertial equilibrium means that the two phases have negligible slip velocity.

Alternatively, on the sub-grid scale level, one may also consider the possibility of small bubbles whose size respond to changes in pressure. This diversity of opinions leads to a variety of modeling approaches. Simulations of cavitating atomizer nozzles invariably require simplifying assumptions. These assumptions should be sufficient to render the problem tractable without producing unacceptable errors. The objective of this work is to construct a three-dimensional CFD solver to simulate flow in a small, high-speed cavitating nozzle using the homogeneous equilibrium model (HEM). The HEM used in this work extends the model described by Schmidt et al. [1,2] in a multidimensional and parallelized framework. The model is extended to simulate the non-linear effects of the pure phase in the flow and the numerical approach differs from the work by Schmidt et al.