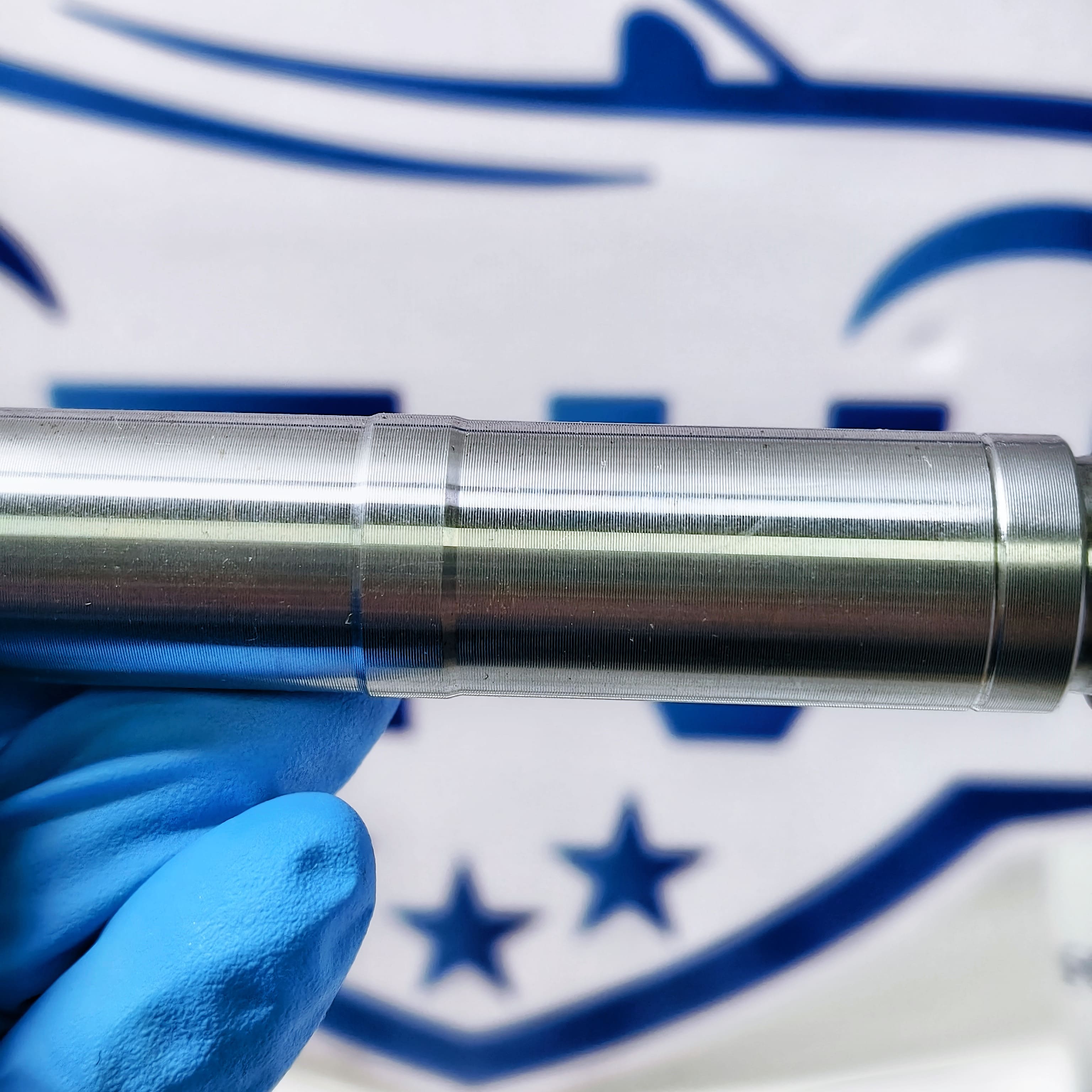

Professional Manufacture 0 445 110 317 Diesel Injector Common Rail Injector Engine Parts Vehicle Parts 0445110317

products description

| Reference. Codes | 0 445 110 317 |

| Application | / |

| MOQ | 4PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Feasibility and Precision Control of 3D Printing for Manufacturing Complex Injector Flow Channels

Abstract

Additive manufacturing (AM, or 3D printing) offers unprecedented geometric freedom for producing complex internal flow channels in fuel injectors, enabling integrated features that are difficult or impossible with conventional machining. This paper reviews the feasibility of using metal and polymer AM technologies for injector flow-path fabrication and summarizes practical strategies to control dimensional accuracy, surface quality, and functional reliability.

1. Technology candidates and feasibility

-

Metal powder-bed fusion (PBF) techniques—Selective Laser Melting (SLM) / Laser Powder Bed Fusion (L-PBF) / Direct Metal Laser Sintering (DMLS)—are the most promising for metallic injector components. They can realize monolithic, highly complex internal channels in high-strength steels, stainless alloys, and nickel-base superalloys used in injector bodies.

-

Electron Beam Melting (EBM) is applicable for certain alloys but offers coarser surface finish.

-

Binder jetting + sintering can produce near-net shapes for some steels with post-sinter densification.

-

Polymeric AM (SLA, two-photon lithography) can prototype microchannels and support optical/flow studies; combined with metal replication techniques it can be useful in R&D.

Feasibility is high for prototyping and low-to-medium volume production provided that the AM process and downstream steps (powder removal, heat treatment, finishing) are engineered for injector requirements.

2. Key challenges specific to injector flow channels

-

Internal surface roughness: As-built Ra from PBF is typically 5–20 µm, which increases hydraulic losses, promotes cavitation nucleation, and affects atomization.

-

Dimensional tolerance and geometric fidelity: Warpage, shrinkage, and residual stress induce dimensional deviations—critical for tight-fit valve seats and orifice alignments.

-

Trapped powder and support removal: Small-diameter or blind channels trap powder; inaccessible powder compromises flow and cleanliness.

-

Porosity and micro-defects: Unmelted particles and lack-of-fusion defects can be leak sources or initiation sites for erosion.

-

Material properties: AM microstructure may differ from wrought equivalents—affecting fatigue, corrosion, and hardness.

3. Precision control and mitigation strategies

-

Design-for-AM (DfAM): Avoid blind cavities; use continuous sweep channels, access ports, and sacrificial escape channels. Incorporate minimum feature sizes and slope limits based on process capability.

-

Process parameter optimization: Optimize laser power, scan speed, hatch spacing, layer thickness, and scan strategy to minimize lack-of-fusion, reduce surface ripples, and lower residual stress.

-

Support and powder management: Design removable or soluble supports; include powder escape channels sized for efficient evacuation; use vibration + pressure wash + ultrasonic cleaning to extract powder.

-

Post-processing for surface & dimensional fidelity:

-

Hot Isostatic Pressing (HIP) to close internal porosity.

-

Thermal stress relief followed by precision machining of critical interfaces (seats, orifice bores).

-

Abrasive Flow Machining (AFM), chemical etching, or electropolishing for internal surface smoothing. AFM is particularly effective for internal passages.

-

Coatings (e.g., PVD/DLC, ceramic) applied after smoothing provide wear/corrosion resistance.

-

-

Metrology & quality assurance: Use industrial CT scanning for internal geometry and porosity assessment, optical CMM for external features, profilometry for surface roughness, and flow-bench testing for hydraulic validation. Statistical process control (SPC) on powder and machine parameters is essential.

-

Hybrid manufacturing: Combine AM for complex features with conventional machining for critical sealing surfaces—machining datum surfaces after AM ensures tight tolerances where needed.

4. Recommendations & application scope

-

Use metal PBF for rapid development and low-/medium-volume injector prototypes with careful DfAM and post-processing.

-

For production components, adopt a validated chain: optimized PBF recipe → HIP → stress relief → precision machining of critical interfaces → internal smoothing (AFM) → coating → CT-based QA.

-

Early-stage testing should include flowbench, cavitation evaluation, and endurance tests with representative fuels.

Conclusion

3D printing is a feasible and powerful route for manufacturing complex injector flow channels, but success depends on an integrated workflow that addresses roughness, trapped powder, porosity, and dimensional control. With appropriate DfAM, process optimization, post-processing, and rigorous metrology, AM can deliver functional injector components with novel internal architectures and competitive performance.

Related products

| 1 | 5WS40200 | 11 | A2C59514909/ | 21 | 31336585 |

| 2 | FA2C53252642 | 12 | A2C59511602 | 22 | 36001726 |

| 3 | 1685796 | 13 | A2C59513556 | 23 | 1709667 |

| 4 | 31303994 | 14 | 5ws40677 | 24 | 36001727 |

| 5 | 50274V05 | 15 | 50274V0 | 25 | 9445R |

| 6 | 5WS40087 | 16 | 5WS40677 | 26 | 00Q1T |

| 7 | 16600-00Q1T | 17 | AV6Q9F593-AB | 27 | 5WS40007 |

| 8 | 00Q0H | 18 | AV6Q9F593-AA | 28 | A2C59513997 |

| 9 | 5WS40148-Z | 19 | A2C59511606 | 29 | 5WS40250 |

| 10 | 2S6Q-9F593-AB | 20 | 16600-00Q0P | 30 | A2C59514912 |