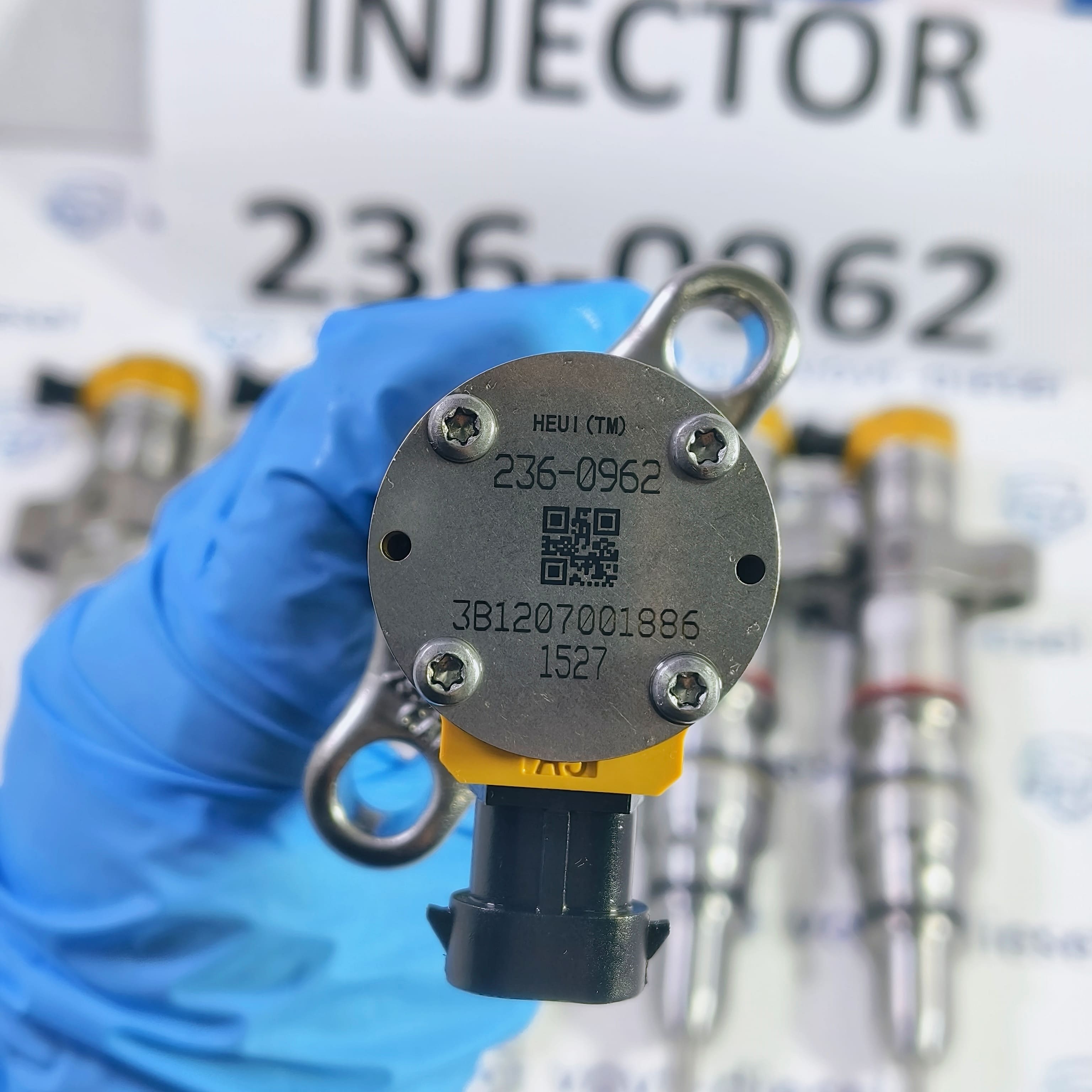

New High Quality Diesel Injector 236-0962 2360962 For CAT

Products Description

| Reference. Codes | 236-0962 |

| Application | 236-0962 |

| MOQ | 4PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~10 working days |

| Payment | T/T, L/C, Paypal, Western Union, MoneyGram or as your requirement |

Synergistic Regulation Mechanism of Different Injection Strategies (Pilot / Main / Post) on Diesel Engine Combustion Process

Abstract

Injection strategies play a decisive role in determining diesel engine combustion efficiency, emissions, and noise. Among them, pilot, main, and post injections form a synergistic control framework to optimize ignition delay, combustion phasing, and pollutant formation. This paper explores the cooperative mechanism of different injection strategies, supported by experimental analysis and computational modeling, with the aim of revealing how injection timing and quantity distribution regulate in-cylinder processes.

1. Introduction

Modern diesel engines operate under stringent emission regulations while maintaining high thermal efficiency. Injection strategy optimization has become one of the most effective approaches to achieving clean combustion. Instead of a single main injection, multiple injections—pilot, main, and post—allow better control of combustion dynamics. Their coordinated use reduces noise, improves atomization, and mitigates the formation of nitrogen oxides (NOx) and particulate matter (PM).

2. Pilot Injection

Pilot injection introduces a small amount of fuel before the main injection event. This process shortens ignition delay by raising in-cylinder temperature and pressure, leading to smoother combustion onset. Experimental results show that pilot injection reduces pressure rise rate and engine noise by 20–30%. However, excessive pilot quantity may cause incomplete combustion and increased hydrocarbon emissions, highlighting the importance of precise control.

3. Main Injection

The main injection delivers the majority of the fuel, directly shaping combustion phasing and thermal efficiency. Its timing relative to top dead center (TDC) determines the balance between efficiency and NOx formation. Earlier main injections increase cylinder pressure and efficiency but may lead to higher NOx emissions, whereas later injections lower NOx but increase soot formation. Thus, main injection acts as the core balancing factor in the synergy mechanism.

4. Post Injection

Post injection introduces a small fuel quantity after the main combustion phase. It enhances oxidation of soot particles by raising local temperature and extending residence time of reactive species. Additionally, post injection contributes to diesel particulate filter (DPF) regeneration in after-treatment systems. However, improper post injection timing may increase fuel consumption and hydrocarbon slip.

5. Synergistic Mechanism

The combined effect of pilot, main, and post injections lies in their complementary roles:

-

Pilot injection stabilizes ignition and reduces noise.

-

Main injection ensures efficient energy conversion.

-

Post injection promotes soot oxidation and supports emission after-treatment.

Through coordinated calibration, multiple injections form a closed-loop control of combustion dynamics, enabling simultaneous reduction of NOx and PM without sacrificing efficiency.

6. Conclusion

Different injection strategies exert distinct yet interconnected influences on diesel engine combustion. Pilot injection improves ignition stability, main injection governs efficiency, and post injection mitigates soot emissions. Their synergistic regulation provides an effective pathway to meet the dual goals of high performance and low emissions in modern diesel engines. Future research should focus on adaptive injection strategies combined with intelligent control systems for real-time optimization under transient operating conditions.