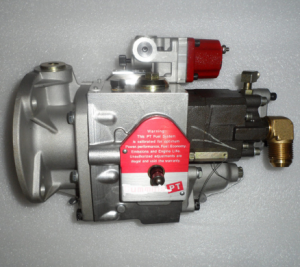

Good Price Diesel Pump Head Rotor 7185-044L Fuel Injection Pump Elements Engine Spare Parts

products description

| Reference. Codes | 7185-044L |

| Application | / |

| MOQ | 2PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, L/C, Paypal, Western Union or as your requirement |

What are the structural components of the pump head?

Role in diesel engine fuel system (taking plunger pump as an example)

1. Generate high-pressure fuel to meet injection requirements

Working principle:

The plunger reciprocates in the pump head, and the volume change of the plunger cavity realizes oil suction and oil compression. When the plunger moves downward, the fuel is sucked in through the inlet valve; when the plunger moves upward, the fuel is compressed (the pressure can reach 100-200MPa or more) and delivered to the injector through the outlet valve.

Key role:

High-pressure fuel can generate sufficient atomization energy at the injector nozzle (for example, the diesel engine injection pressure needs to reach more than 120MPa to atomize the fuel into 5-20μm particles).

The diameter and stroke of the pump head plunger directly affect the fuel supply (for example, the plunger diameter of a heavy truck diesel engine is about 8-10mm, and the stroke determines the single injection amount).

2. Control injection timing and oil distribution

Timing control:

The cam shape of the pump head camshaft determines the phase of the plunger movement, thereby controlling the start and end of the injection (e.g. the diesel engine injection advance angle needs to be accurate to ±1° crankshaft angle).

Oil volume adjustment:

By adjusting the effective stroke of the plunger (such as the rack or solenoid valve control of the diesel engine injection pump), the volume of each pump oil is changed to achieve precise control of the oil volume when the load changes (e.g. the oil supply at idle speed is only 10%-20% of the full load).

3. Maintain stable pressure in the fuel system

The pressure relief ring of the pump head oil outlet valve (similar to the oil outlet valve structure) quickly reduces the pressure in the high-pressure oil pipe when the plunger stops supplying oil, preventing the injector from dripping or secondary injection (e.g. the pressure relief volume is usually 0.5-1.5mm³).

Role in gasoline engine fuel system (taking high-pressure fuel pump as an example)

1. Provide high-pressure fuel for direct injection in cylinder

Working principle:

Gasoline engine high-pressure fuel pump (such as direct injection system in cylinder) is usually plunger type or gear type, driven by camshaft, pressurizing fuel from low-pressure oil circuit (0.3-0.5MPa) to 5-20MPa (adjusted according to working conditions).

Key role:

High-pressure fuel is directly injected into the cylinder through the injector during the compression stroke, and stratified combustion is achieved in conjunction with the shape of the combustion chamber (such as injection pressure of about 5MPa at idle speed and 20MPa at full load).

2. Cooperate with ECU to realize on-demand fuel supply

The pressure regulating valve (PCV valve) in the pump head adjusts the fuel supply pressure according to the ECU signal:

Reduce pressure at low load (reduce energy consumption), increase pressure at high load (ensure atomization quality), and avoid overheating and gasification of fuel (gas blockage).

Auxiliary functions and structural design of pump head

1. Fuel filtration and lubrication

A filter or oil inlet filter is usually set inside the pump head (such as the precision of the oil inlet filter of a diesel engine injection pump is about 50μm) to prevent impurities from entering the plunger pair (the matching clearance is only 3-5μm) to avoid abnormal wear.

When the fuel flows in the pump head, it also has a lubricating effect (such as the oil film formed between the diesel engine plunger and the plunger sleeve by the fuel, and the fuel must contain an appropriate amount of lubricating components).

2. Sealing and high-pressure resistance design

The pump head housing is made of high-strength alloy material (such as ductile iron or aluminum alloy), with precision machined sealing surface (such as the flatness of the plunger sleeve and pump head joint surface ≤10μm) to prevent high-pressure fuel leakage.

Key seals (such as O-rings, oil seals) are made of oil-resistant rubber (such as fluororubber) to adapt to fuel corrosion and high temperature environment (working temperature can reach 120-150℃).

Impact of pump head failure on the system and maintenance points

1. Common failures and consequences

Plunger wear: leads to insufficient fuel supply pressure, difficulty in starting the diesel engine, and power reduction (such as increased leakage after wear of the plunger pair, and a significant impact on performance when the fuel supply is reduced by more than 10%).

Poor sealing of the oil outlet valve: The pressure holding capacity in the high-pressure oil pipe decreases, and the injector drips oil, resulting in incomplete combustion and black smoke from the exhaust pipe.

Abnormal noise of gasoline engine high-pressure oil pump: Camshaft wear or air in the fuel may cause abnormal wear of the pump head and even cause fuel leakage (check whether the fuel filter is blocked).

2. Maintenance key

Diesel engine pump head: Regularly replace the fuel filter (filtration accuracy ≤5μm), avoid using inferior fuel (sulfur content >0.05% is easy to corrode the plunger surface); perform pump head calibration every 50,000-100,000 kilometers (such as adjusting the fuel supply timing and plunger stroke).

Gasoline engine high-pressure fuel pump: avoid running at low fuel volume (to prevent the fuel pump from overheating); pay attention to compatibility when changing fuel (e.g. ethanol gasoline requires the use of alcohol-resistant seals); and promptly check the pump head pressure when a start-up delay occurs (the standard pressure can be read through a diagnostic instrument).