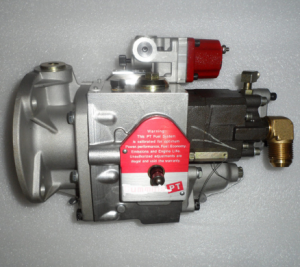

Good Price Diesel Pump Head Rotor 7180-340W Fuel Injection Pump Elements Engine Spare Parts

products description

| Reference. Codes | 146402-0920 |

| Application | / |

| MOQ | 2PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, L/C, Paypal, Western Union or as your requirement |

Research on the structural characteristics, performance optimization and fault diagnosis of diesel pump heads

Abstract

As the core component of the diesel engine fuel injection system, the diesel pump head undertakes the key functions of fuel pressurization, metering and precise delivery. Its performance directly affects the engine's power output, fuel economy and emission indicators. This paper takes the diesel pump head as the research object, systematically analyzes its structural composition and working principle, explores the key factors affecting its performance, proposes a diagnostic method based on typical fault cases, and explains the technology upgrade path from three dimensions: material innovation, structural optimization and intelligent control. The study shows that the adaptability of the diesel pump head can be significantly improved by improving the matching accuracy of the parts through precision manufacturing processes, extending the service life by using wear-resistant and anti-corrosion materials, and realizing dynamic adjustment by integrating the electronic control system, providing technical support for meeting the National VI and Euro VII emission regulations.

1. Introduction

In the diesel engine power system, the accuracy of the fuel injection system determines the combustion efficiency and emission level, and the diesel pump head, as the "pressure core" of the system, pressurizes the low-pressure fuel to 1000-2000bar through mechanical or electronic control methods, and accurately distributes it to each cylinder according to the engine working conditions. With the advancement of the "dual carbon" goal and the implementation of stringent emission regulations such as National VI b and Euro VII, traditional mechanical pump heads can no longer meet the requirements of high precision and low emissions, pushing pump head technology towards high pressure, electronic control and integration.

The technical iteration of diesel pump heads needs to balance three core contradictions: one is the contradiction between high pressure and structural reliability (high pressure can easily lead to increased wear of components); the second is the contradiction between metering accuracy and response speed (high precision requires more complex control mechanisms); the third is the contradiction between cost control and performance improvement (new materials and precision manufacturing will increase costs). This article analyzes the relationship between the structure and performance of the pump head to provide a theoretical reference for its design optimization and troubleshooting.

2. Structural composition and working principle of diesel pump heads

(I) Core structural composition

The structure of the diesel pump head must meet the requirements of high-pressure sealing, precise metering and wear resistance, and is mainly composed of the following key components:

Plunger pair

It consists of a plunger and a plunger sleeve, and is the core unit for fuel pressurization. The plunger surface is processed with spiral grooves or bevel grooves, which can change the effective stroke by rotation (mechanical pump) or control the stroke by a solenoid valve (electronic control pump) to achieve fuel supply adjustment. The clearance between the two must be controlled within 0.001-0.003mm to ensure high-pressure sealing and reduce friction and wear. The material is mostly chromium tungsten manganese steel after nitriding treatment, and the surface hardness reaches HRC60 or above.

Oil outlet valve pair

Includes the oil outlet valve and the valve seat, which realizes high-pressure cutoff through the conical sealing surface. Its pressure relief ring can quickly reduce the residual pressure of the high-pressure oil pipe after the oil supply is completed to avoid dripping of the injector. The matching accuracy of the inner hole of the valve seat and the pressure relief ring directly affects the pressure relief effect. After wear, it will cause "secondary injection" and increase fuel consumption and emissions.

Drive and transmission mechanism

It is composed of camshaft and tappet assembly. The cam profile (lift, phase) determines the movement law of the plunger: the near rest section ensures sufficient oil suction, the far rest section ensures stable oil pressure, and the transition section reduces impact. On this basis, the electronically controlled pump head adds a solenoid valve or piezoelectric actuator to realize electronic control of the oil supply time.

Oil quantity control mechanism

The mechanical pump head adjusts the oil supply through the rack and fork linkage plunger rotation; the electronic control pump head is controlled by the ECU to control the opening of the solenoid valve, accurately adjust the flow of the fuel metering unit (FMU), and the response time can be less than 0.5ms to meet the needs of multi-stage injection.

(II) Working principle

The working process of the diesel pump head can be divided into four stages: oil suction - oil pressure - oil supply - pressure relief. Take the electronic control high-pressure common rail pump head as an example:

Oil suction stage: The camshaft drives the tappet downward, and the plunger moves downward accordingly. The volume of the pump chamber increases to form a negative pressure. The low-pressure fuel enters the pump chamber through the inlet valve. At this time, the outlet valve is closed under the action of the spring force to prevent backflow.

Oil pressure stage: The cam lifts the tappet, the plunger moves upward to compress the fuel, and the pressure in the pump chamber rises suddenly. When the pressure exceeds the preload of the outlet valve spring, the outlet valve opens, and the high-pressure fuel enters the common rail pipe through the oil channel.

Fuel supply stage: ECU adjusts the opening of the solenoid valve according to the speed and load signal, controls the effective stroke of the plunger, accurately measures the fuel supply, and realizes closed-loop control through the feedback of the common rail pressure sensor, and controls the pressure fluctuation within ±5bar.

Pressure relief stage: Before the plunger moves down to the end point, the solenoid valve is powered off, the oil outlet valve is closed, the pressure relief ring cuts off the high-pressure oil circuit, and the pump chamber pressure drops sharply, preparing for the next oil suction, avoiding the residual pressure from affecting the injection accuracy.

III. Key factors affecting the performance of diesel pump heads

(I) Influence of structural parameters

Plunger matching accuracy: For every 0.001mm increase in matching clearance, the volumetric efficiency decreases by 1.2%-1.5%, and the high-pressure fuel scouring is aggravated, resulting in a shortening of the matching life by more than 30%. Experiments show that reducing the clearance from 0.003mm to 0.002mm can improve the pump head pressure stability by 25%.

Cam profile design: Symmetrical cams (such as equal acceleration-equal deceleration curves) can reduce plunger impact and reduce pressure fluctuations by 15%; asymmetric cams are more suitable for high-speed conditions, and the oil supply deviation can be controlled within ±2% at 4000r/min.

Oil outlet valve pressure relief ring size: When the ring diameter increases by 0.02mm, the residual pressure drops by about 30bar, but too large will cause oil supply lag; shortening the ring length will speed up the pressure relief speed, which is easy to cause "early injection", and needs to be matched according to the model (such as the ring length of heavy-duty diesel engines is mostly 1.5-2mm).

(II) Fuel quality and working environment

Fuel impurities and viscosity: Mechanical impurities in fuel (particle size > 5μm) will cause the wear rate of plunger pairs to increase by 5 times, and excessive sulfur content (> 500ppm) will aggravate the corrosion of the oil outlet valve sealing surface. In a low temperature environment (-20℃), the viscosity of diesel increases to more than 40mm²/s, the oil absorption resistance increases, and cavitation is easy to cause.

Temperature and vibration load: After the engine is heated up, the temperature of the pump head can reach 120-150℃, causing thermal expansion of the material and a change in the clearance of 0.001-0.002mm; long-term vibration (amplitude>0.5mm) will aggravate the contact fatigue between the cam and the tappet, resulting in pitting and peeling.

(III) Optimization of control strategy

The performance of the electronically controlled pump head depends on the ECU control algorithm: "small pulse width high frequency injection" (pulse width 0.8-1.2ms) is used in idle conditions, which can reduce emissions by 30%; "large pulse width steady flow injection" is switched at high speed and high load to ensure power output. Test data shows that the fuzzy PID algorithm is used to adjust the common rail pressure, and the response speed is 40% higher than that of the traditional PID, and the dynamic error is <3%.

IV. Common faults and diagnostic methods of diesel pump heads

(I) Typical fault analysis

Insufficient pressure: manifested as reduced engine power and black smoke. The main reasons include: wear of plunger pairs (fit clearance>0.005mm), poor sealing of the oil outlet valve, and insufficient lift caused by wear of the cam profile. In one case, piston wear caused the pump pressure to drop from 1800 bar to 1500 bar, and fuel consumption increased by 8%.

Leakage failure: Leakage at the joint surface between the piston sleeve and the pump body is mostly due to aging of the sealing copper gasket; leakage at the oil outlet valve seat is caused by scratches on the sealing cone surface, which needs to be repaired by grinding (the roughness needs to be below Ra0.02μm).

Uneven oil supply: When the oil supply deviation of each cylinder of the multi-cylinder pump head is greater than 3%, the engine will experience idle jitter, which is mainly caused by rack jamming, plunger spiral groove processing error or inconsistent solenoid valve response, and needs to be calibrated by the test bench (the deviation is controlled within ±1.5%).

(II) Diagnostic technology

Pressure waveform analysis method: The pressure waveform of the pump head oil outlet is collected by an oscilloscope. The normal waveform should be "trapezoidal" (fast pressure increase, flat pressure stabilization, and steep pressure relief); if "sawtooth fluctuations" appear, it means that the plunger pair is worn; "slow pressure relief" indicates that the pressure relief ring belt has failed.

Precision measurement method: Use a three-coordinate measuring instrument to detect the straightness of the plunger (≤0.002mm/100mm) and the roundness of the oil outlet valve (≤0.001mm). Parts that exceed the tolerance must be replaced.

Bench test verification: On the fuel injection pump test bench, simulate the full working condition test (speed 800-4000r/min), record the fuel supply and pressure stability under each working condition, and unqualified pump heads need to be disassembled and repaired.

V. Optimization design and technology upgrade of diesel pump heads

(I) Innovation of materials and manufacturing processes

Application of wear-resistant materials: The plunger pair is made of tungsten carbide-based cemented carbide (WC-Co), and the surface is sprayed with diamond-like coating (DLC), with a hardness of more than HV2500 and a wear resistance of 5 times; the pump body is made of isothermal quenching ductile iron (ADI), with a strength of 1200MPa and a weight reduction of 20% compared with the steel pump body.

Precision manufacturing technology: The plunger hole is processed by ultra-precision honing process, and the surface roughness is reduced to Ra0.01μm; 3D printing technology is used to manufacture the oil valve seat, realizing the integrated molding of complex flow channels, reducing the flow resistance by 15%, and reducing the pressure loss by 8%.

(II) Structural optimization

Multi-plunger collaborative design: The four-plunger pump head is arranged with a phase difference of 90°, and the flow pulsation is reduced from ±8% to ±3%. With the common rail pressure storage chamber design, the pressure fluctuation is further reduced to ±2bar.

Integrated layout: The oil control unit, pressure sensor and pump head are integrated into one design to reduce pipeline connections, shorten the response time from 1.2ms to 0.6ms, and meet the requirements of Euro VII regulations for transient emissions.

(III) Intelligent upgrade

Adaptive control: Based on the deep learning algorithm, the ECU collects parameters such as fuel temperature, viscosity, rail pressure, etc. in real time, dynamically adjusts the injection pulse width and pressure, and controls the fuel supply error within ±1% in an environment of -30℃ to 50℃.

Predictive maintenance: Built-in vibration sensor and temperature sensor transmit data to the cloud through the Internet of Things, establish a life prediction model, and warn of plunger wear in advance (prediction accuracy > 90%), reducing downtime maintenance time.

VI. Conclusion and Outlook

The technological development of diesel pump heads has always been centered around the goal of "high pressure, high precision, and high reliability". Through the collaborative innovation of structural optimization, material innovation, and intelligent control, it has achieved a leap from mechanical control to electronic control closed loop. In the future, with the promotion of alternative fuels (such as biodiesel and methanol), pump heads need to further improve corrosion resistance (using special materials such as Hastelloy); at the same time, collaborative control with hybrid systems (such as maintaining common rail pressure during shutdown) will become a new research direction. Through continuous technological breakthroughs, diesel pump heads will play a more critical role in the efficient and clean combustion of diesel engines, providing core support for the realization of the "dual carbon" goals in the transportation field.