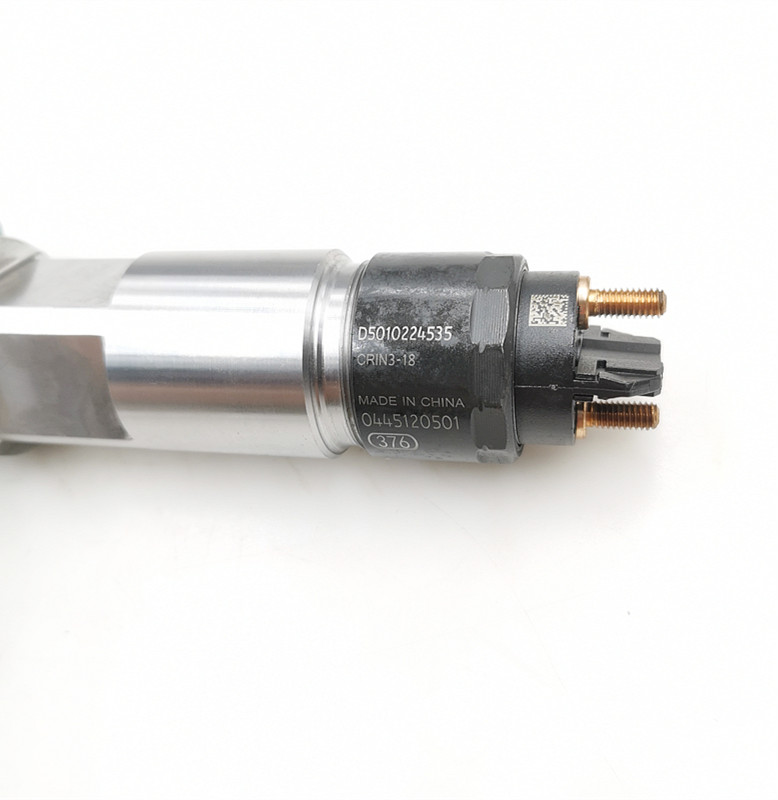

Diesel Injector Fuel Injector 0445120501 compatible with injector Truck D5010224535

| Produce Name | 0445120501 |

| Engine Model | / |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Of course, some achievements have also been made in China. Common optimization methods include: I} sensitivity analysis method. Peng Wen M optimized the layout and thickness of the column reinforcement plates of the machine tool as parameters, and took the number, thickness, width and position of the reinforcement plates as variables, and the optimization effect was quite ideal. Liu Cheng, Hua Jun et al. used the first order natural frequency of the bed as the objective function of structural optimization, and took the mass, stiffness and damping as the design variables respectively. Finally, the natural frequency was increased and the amplitude was reduced, and the optimization effect was obvious. In this paper, the sensitivity analysis method will be used in the follow-up structural dynamic analysis and lightweight design. 2) Energy balance method. Zhang Zonglan M established the concentrated mass model of the optical curve grinder, applied the mathematical model to the theoretical analysis and energy calculation of the machine tool, and then used the energy balance method to analyze and optimize the key components. Zheng Weizhong used the mass model to calculate the energy distribution of M1432A universal cylindrical grinding machine wheel frame, and found out the weak parts of the whole machine by the method of energy balance, which provided the foundation for the anti-vibration optimization design of the rear wheel frame components. 3) Topology optimization of machine tool components to improve stiffness and reduce quality. Based on the method of topology optimization, Wang Yan uses Optistmct to find out the key parts of grinding machine through modal analysis, and carries out dynamic optimization. Liu Chengying, Tan Feng et al. proposed a structural method based on topology optimization, reinforcement plate form selection, layout and size optimization, which finally effectively improved the natural frequency and reduced the resonance amplitude, with obvious optimization effect.