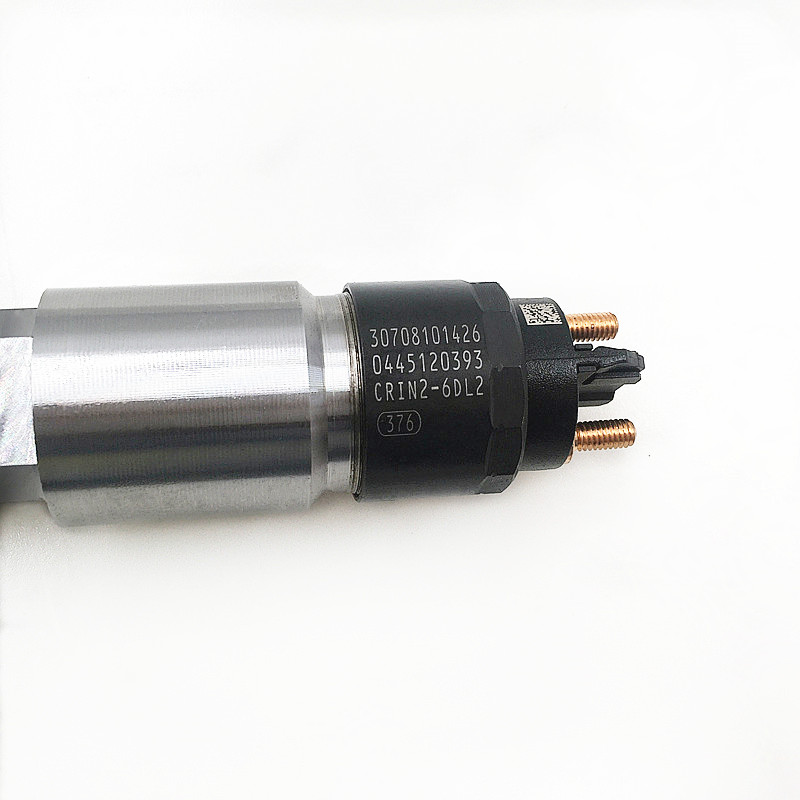

Diesel Injector Fuel Injector 0445120078 0445120393 Bosch for Soyat Car Wuxisida Engine Deutz 1112010630

| Produce Name | 0445120078 0445120393 |

| Engine Model | Deutz 1112010630 |

| Application | Soyat Car |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

a. The fuel consumption of the whole vehicle with the engine is 5.55L in 100 km under NEDC cycle condition. Compared with the actual fuel consumption of the whole vehicle of the original model of 5.50L in 100 km (actual test), the error is only.91%. It can be considered that the built Cruise vehicle model is a real model, and the matching calculation of the engine carrying the vehicle can be carried out on this model. b. The calculated and experimental curves are in good agreement, and the error is less than 5%. It can be considered that the built Boost engine model has a certain accuracy and reliability, can simulate the actual characteristics, and can be used for the optimization calculation of the engine. e. The self-developed valve mechanism software and EXCITE Timing Driver software were used to optimize and design two sets of valve mechanism configuration lines. The designed CAM profile met the kinematic requirements of valve mechanism, such as K series, spring margin and setting speed, and the contact stress of CAM tappt was within the allowable range. Within the range of calibrated speed, there are no phenomena such as flying off, bouncing back and spring coaming. d. Using the optimized CAM profile, with reasonable valve timing and VVT strategy, the engine fuel consumption is reduced. e. The optimized performance parameters were used for vehicle matching calculation, and the fuel consumption per 100 km was 5.36L in NEDC cycle condition, which was 3.4% lower than 5.55L in the prototype. f. Firstly, Cruise software is used to build the vehicle model, and some key working conditions of this gasoline engine in the vehicle test cycle are found out. Then, the optimization calculation of these working conditions is carried out by using Boost software, and the optimization direction is proposed. Then, the self-developed valve mechanism software and EXCITE Timing Driver software are used to optimize the valve mechanism design, and the results are returned to the Cruise vehicle model for verification. This simulation calculation process is effective for engine optimization design.