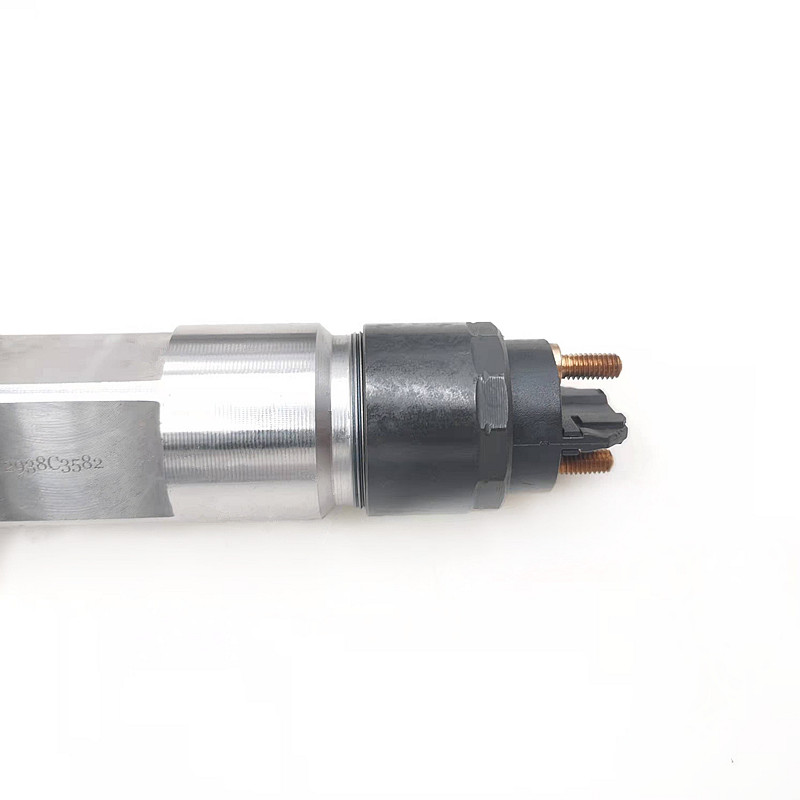

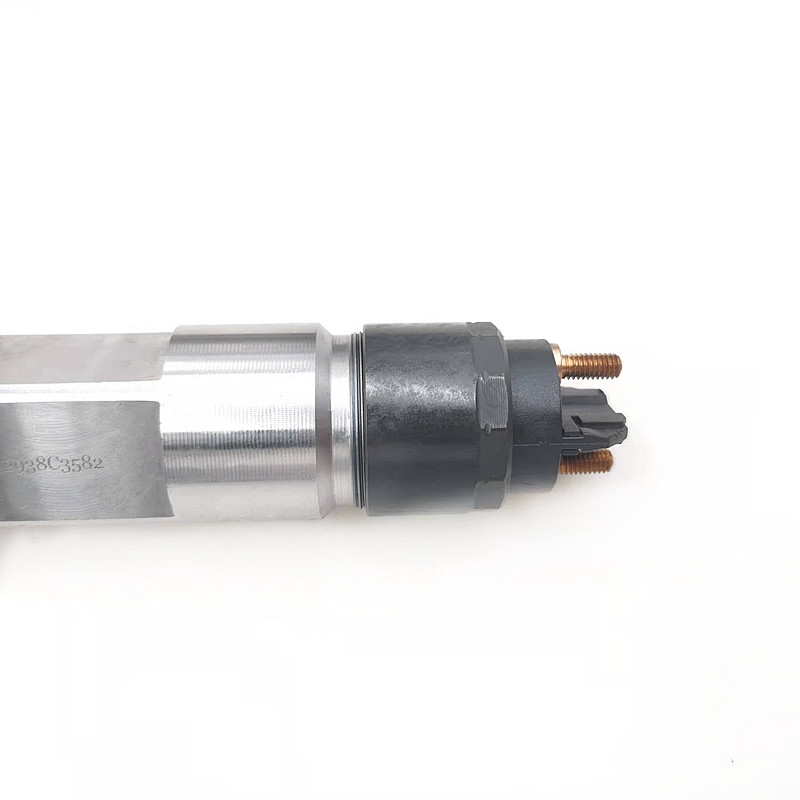

Diesel Injector Fuel Injector 0445120056 Bosch for Man Engine

| Produce Name | 0445120056 |

| Engine Model | MAN engine |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Dynamic cavitation inside a high performance diesel injector – an experimental and CFD investigation (part 1)

Abstract.

A combination of simulation and special experimental techniques has been used to investigate the transient flow and cavitation phenomena of a control device inside a high performance diesel injector. Dynamic cavitation behaviour was captured on a large scale transparent model, which was then used to develop and validate an advanced turbulence CFD model with Large Eddy Simulation. These techniques are used within Delphi to gain insight and optimise injector performance at real-size.

1 Introduction

The diesel injector is arguably the most important element in achieving premium engine performance with low emissions. It therefore follows that injectors for high performance engines must be controlled with precision. As a result, the hydraulic control valves and orifices must be designed and manufactured with high accuracy, and understanding their fundamental behaviour will provide an important contribution to the optimisation and fine-tuning process. Delphi uses a combination of simulation and special experimental techniques to investigate the flow characteristics of these devices.

As with all new injectors, a High Performance Diesel Injector under development at Delphi has been the subject of much simulation activity. Of particular interest to this paper, are the CFD investigations of the hydraulic control functions.

Flow cavitation is a familiar topic in diesel injection equipment; previous experimental experience showed that the industry standard Reynolds-Averaged Navier-Stokes (RANS) modelling was unable to give accurate results for dynamic cavitation behaviour. Hence in addition to the CFD work, large scale models (LSM) of different parts of the hydraulic control functions were commissioned. The use of transparent models of control valves and orifices at greatly increased scales enables a developed understanding of hydraulic performance [1] that is not easily achievable with other techniques. The hydraulic performance is sufficiently independent across all scales to be useful as a development tool [2].