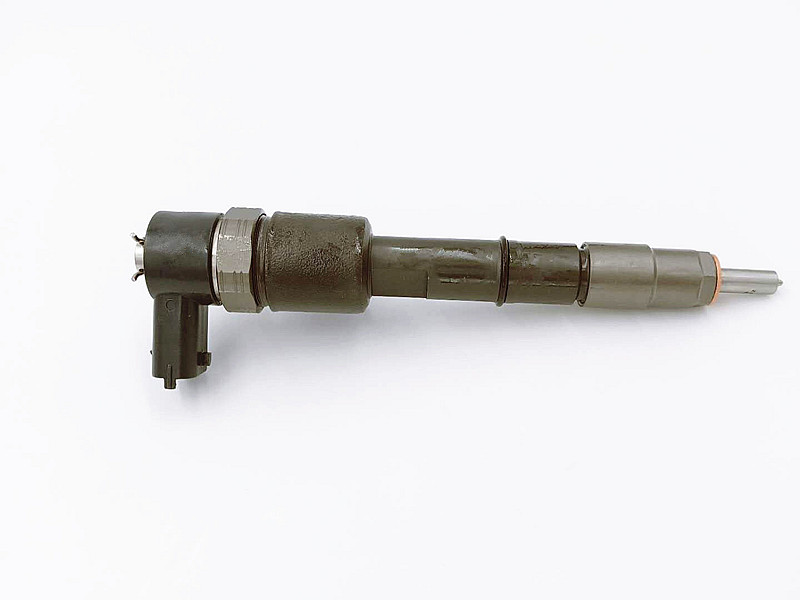

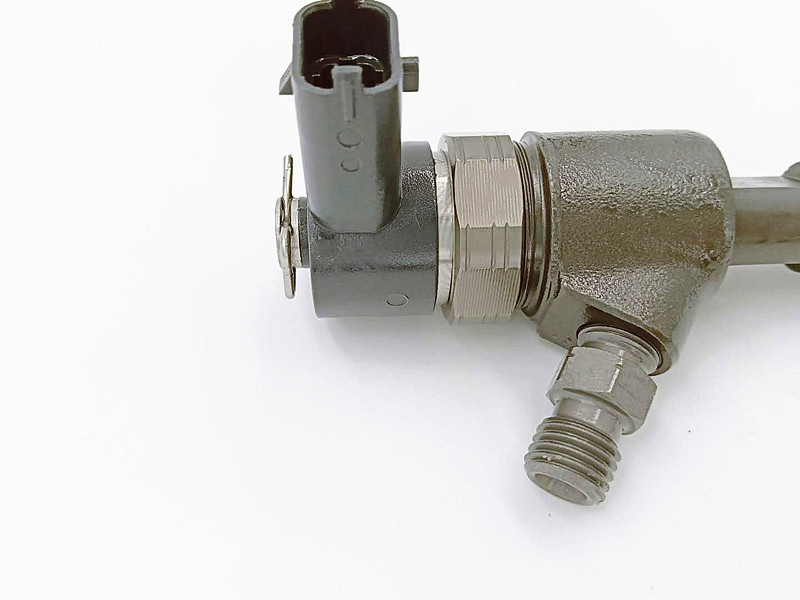

Diesel Injector Fuel Injector 0445110821 Bosch for FAW Jiefangfoton, XCMG, FAW Jiefang, Shacman, Sinotruk (CNHTC) , JAC

products detail

Used in Vehicles / Engines

| Product Code | 0445110821 |

| Engine Model | / |

| Application | FAW Jiefang Foton, XCMG, FAW Jiefang, Shacman, SINOTRUK (CNHTC), JAC |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Our advantage

- 1 Competitive price

- 2 Ready stock

- 3 Fast delivery

- 4 100% tested before shipped

- 5 Small order allowed

How DENSO common rail injectors work

DENSO leads the industry in increasing fuel pressure and maximizing the precision of injection timing and quantity, achieving cleaner emissions and more powerful engines. DENSO's common rail systems are supplied to a variety of vehicles including passenger cars and commercial vehicles.

Diesel engines combine excellent fuel economy and power, and their popularity is growing. The development of the common rail system is a landmark in significantly improving the diesel engine capabilities.

The common rail system accumulates high-pressure fuel in the common rail and injects the fuel into the engine cylinder at timing controlled by the engine ECU, allowing high-pressure injection independent from the engine speed. As a result, the common rail system can reduce harmful materials such as nitrogen oxides (NOx) and particulate matter (PM) in emissions and generates more engine power.

The diesel common rail system is now the most commonly used fuel injection system for diesel engines. First commercialised by DENSO, it enables the engine to have greater control over the pressure of fuel injection, leading to a more reliable and efficient combustion process.

After the fuel has been pressurised within the fuel pump, it is stored in the common rail system, also known as the accumulator, before being sprayed via the injectors into the combustion chambers. Each of these injectors can be adjusted within set limits depending on the required fuel pressure and timing for the delivery of fuel. Unaffected by the engine’s rotation speed, having multiple injectors available to send fuel to the engine at different pressures or times enables a greater level of flexibility in terms of the level of power, fuel consumption and emissions that are produced by the engine.