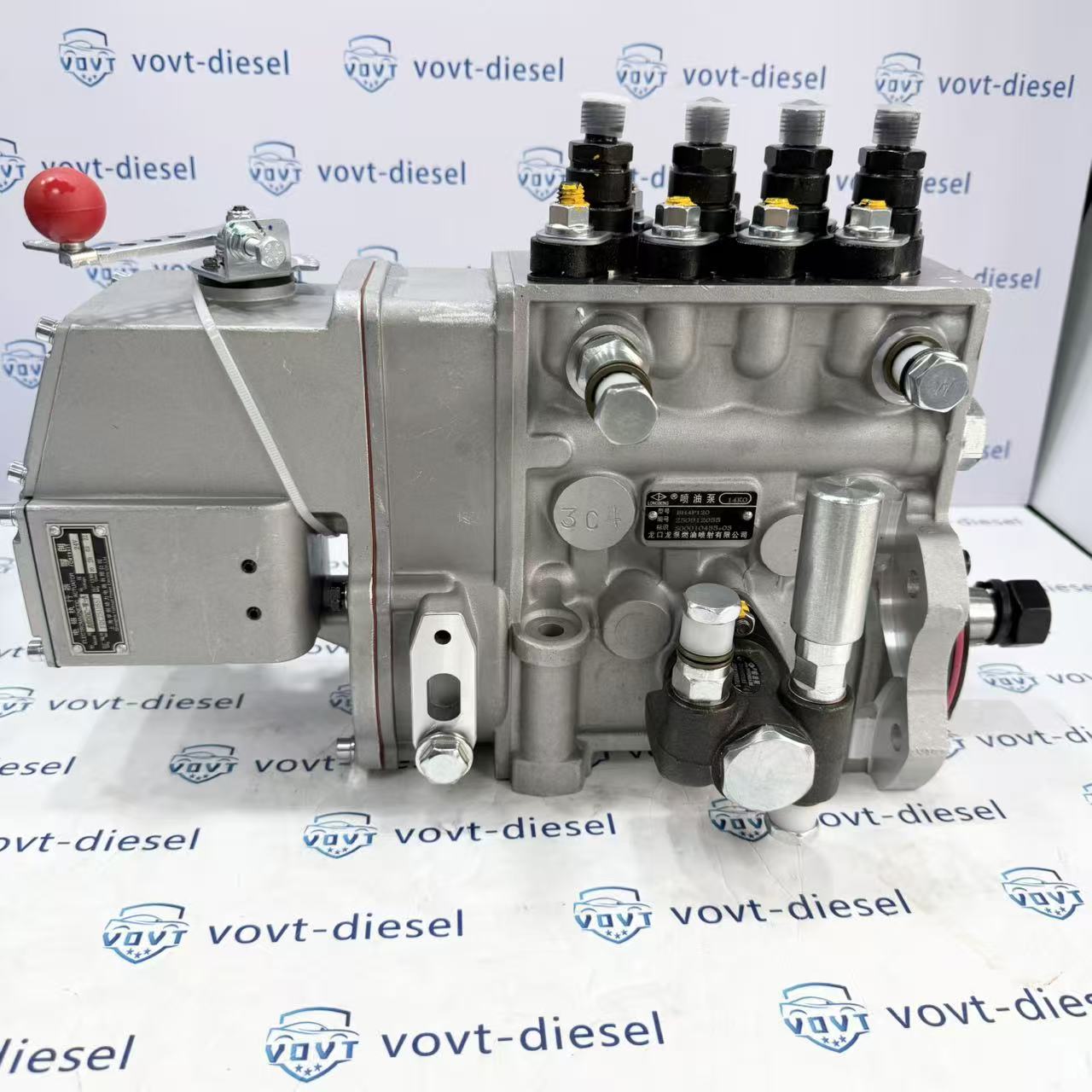

Diesel Fuel Injection Pump BH4P120 Engine Auto Engine Part

products description

| Reference Code | BH4P120 |

| MOQ | 1 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Western Union, Money Gram, Paypal, Alipay, Wechat |

Flow Rate Stability Analysis of Oil Pumps under Different Speed Conditions

Abstract

Oil pumps are critical components in automotive, construction machinery, and hydraulic systems, responsible for fuel delivery and pressure regulation. The stability of pump flow rate directly affects system efficiency, combustion uniformity, and overall reliability. Under varying rotational speeds, flow behavior is influenced by fluid dynamics, leakage, cavitation, and control mechanisms. This paper analyzes the mechanisms of flow instability at different speed conditions, outlines modeling and experimental verification methods, and discusses strategies for stabilizing flow fluctuations.

1. Characteristics of Flow Instability

Flow instability manifests differently depending on operating conditions:

-

Transient Pulsation: Periodic fluctuations that occur at the fundamental or harmonic frequency of the pump speed.

-

Low-Frequency Drift: Gradual deviations in flow rate caused by sudden load changes or step variations in rotational speed.

-

Random Disturbances: Stochastic oscillations induced by cavitation, trapped gas, or valve-induced turbulence.

These forms of instability, if not controlled, may result in increased vibration, reduced efficiency, or premature wear of system components.

2. Mechanistic Differences among Pump Types

-

Positive Displacement Pumps (gear and plunger pumps): Theoretical flow rate is determined by rotational speed and displacement per cycle

Qt=n⋅Vs, where n is rotational speed and V_s is swept volume. However, leakage, elastic deformation, and pressure ripple reduce effective stability at high speeds.

-

Dynamic Pumps (centrifugal pumps): Flow rate is more sensitive to speed due to velocity head,

Q∝n, but is also strongly influenced by hydraulic losses and cavitation at elevated rotational speeds.

3. Factors Influencing Flow Stability

-

Mechanical Inertia: Rapid acceleration or deceleration causes delay in flow response.

-

Leakage and Clearance Effects: Increased clearance under high pressure reduces volumetric efficiency and introduces unsteady leakage flow.

-

Fluid Compressibility and Cavitation: Entrained gas or vapor bubbles generate compressibility effects, amplifying pulsations at high speed.

-

Control System Characteristics: The response time of regulating valves or electronic control units affects dynamic stabilization.

4. Modeling and Experimental Approaches

Computational Fluid Dynamics (CFD) is widely applied to capture internal flow distribution and pulsation patterns. Coupled structural–fluid simulations can reflect deformation-induced leakage effects. On the experimental side, high-frequency flow sensors and pressure transducers are used to measure pulsation amplitude under variable-speed test rigs, enabling validation of numerical predictions.

5. Strategies for Flow Stabilization

-

Structural Optimization: Reducing dead volumes, improving valve geometry, and enhancing sealing interfaces to minimize leakage and pulsation.

-

Speed Control Algorithms: Adaptive PID or model predictive control can smooth transient responses when rotational speed changes.

-

Auxiliary Components: Use of accumulators or damping chambers to absorb pressure fluctuations.

-

Material and Coating Improvements: Enhancing wear resistance of contact surfaces to ensure long-term dimensional stability and flow consistency.

Conclusion

The stability of oil pump flow rate under varying speed conditions is governed by the interplay of mechanical, hydraulic, and control factors. Understanding the mechanisms of pulsation, drift, and random disturbances is essential for system optimization. Through integrated numerical simulation, experimental validation, and design refinement, the negative effects of flow instability can be effectively mitigated, thereby improving reliability and service life of modern fuel and hydraulic systems.