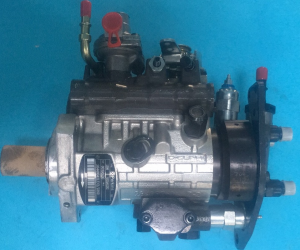

Diesel Fuel Injection Pump 729932-51400 Engine Auto Engine Part

products description

| Reference Code | 729932-51400 |

| MOQ | 1 PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, Western Union, Money Gram, Paypal, Alipay, Wechat |

Reliability Enhancement of Oil Pumps under Transient and Abnormal Operating Conditions

Oil pumps are essential components in lubrication and hydraulic systems, where stable operation is critical for ensuring mechanical reliability. In practical applications, oil pumps frequently encounter transient and abnormal operating conditions, such as sudden speed changes, oil aeration, cavitation, and short-term oil starvation. These conditions can significantly degrade pump performance and accelerate component failure. This study investigates methods to enhance oil pump reliability under such non-ideal operating environments.

The research first analyzes the influence of oil aeration on pump suction characteristics. Entrained air reduces effective oil bulk modulus, leading to unstable pressure build-up and increased flow fluctuations. A modified inlet structure incorporating an air–oil separation chamber is proposed to improve suction stability. Simulation results indicate that the optimized inlet design reduces pressure fluctuation amplitude by approximately 25% during aerated oil operation.

Cavitation is another major threat to oil pump durability, particularly during high-speed or cold-start conditions. To mitigate cavitation erosion, the study evaluates the effectiveness of pressure-equalizing grooves and anti-cavitation relief channels integrated into the pump housing. Experimental observations show a noticeable reduction in cavitation-induced vibration and surface damage compared with conventional designs.

In addition, short-term oil starvation caused by aggressive vehicle maneuvers or uneven oil distribution is examined. A passive oil reserve mechanism is introduced, allowing temporary compensation for oil supply interruptions. Bench tests demonstrate that the mechanism can sustain minimum lubrication pressure for several seconds, significantly reducing the risk of scuffing and bearing damage.

The study also addresses abnormal load scenarios by introducing condition-based monitoring using vibration and pressure signal features. Early detection of abnormal operating states enables preventive control actions, such as speed limitation or flow redistribution, to protect the pump and connected components. Compared with traditional protection strategies, this approach provides earlier fault recognition and improved system resilience.

Overall, the results show that enhancing oil pump reliability under transient and abnormal conditions requires a combination of structural optimization, flow control strategies, and intelligent monitoring. The proposed solutions improve operational robustness without significantly increasing system complexity, offering practical value for automotive and industrial oil pump applications.